Leading trailing shoe drum brake applying force through trailing shoe giant magnetostictive and method thereof

A giant magnetostrictive, drum brake technology, applied in drum brakes, brake types, gear shifting mechanisms, etc., can solve the problem that the two-way double leading shoe brake cannot be equipped with a parking brake, the shoe braking efficiency is low, Problems such as poor braking stability, to achieve the effect of convenient arrangement of parking brake mechanism, good compression performance and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

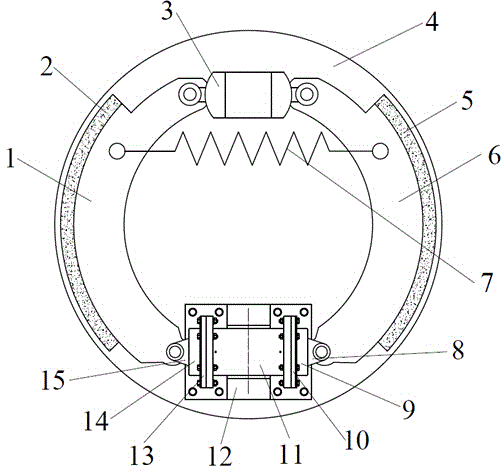

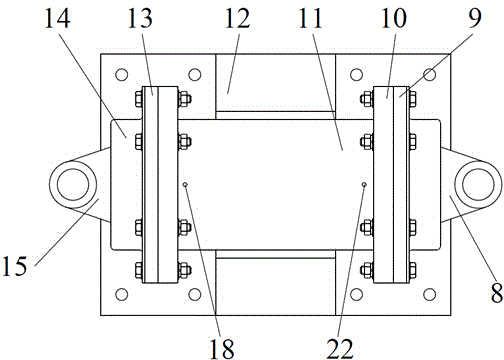

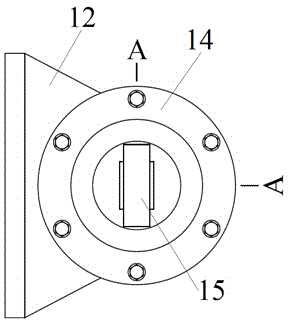

[0033] Such as figure 1 , 2 , shown in 3, 4, 5, a kind of lead-slave drum-type brake that adds force from hoof supermagnetostriction comprises left brake shoe 1, left brake pad 2, brake wheel cylinder 3, brake drum 4, Right brake pad 5, right brake shoe 6, return spring 7, super magnetostrictive booster from the shoe, the super magnetostrictive booster from the shoe includes right connector 8, right limit cover 9, right coil fixation Cover 10, booster shell 11, booster base 12, left coil fixing cover 13, left limit cover 14, left connector 15, left elastic rubber washer 16, left adjusting gasket 17, left outlet hole 18, Giant magnetostrictive column 19, excitation coil 20, coil bobbin 21, right outlet hole 22, right adjusting pad 23, right elastic rubber washer 24, from the hoof giant magnetostrictive booster through the booster base 12 fixed on the system Below the inside of the moving drum 4, the brake wheel cylinder 3 is fixed above the inside of the brake drum 4, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com