Tightening torque applying device

A technology of tightening torque and sun gear, applied in transmission, gear transmission, metal processing, etc., can solve the problems of metal sealing ring damage, slow screw assembly and loading speed, uneven force on metal sealing ring, etc. Assembly process, shortening assembly time, the effect of increasing assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

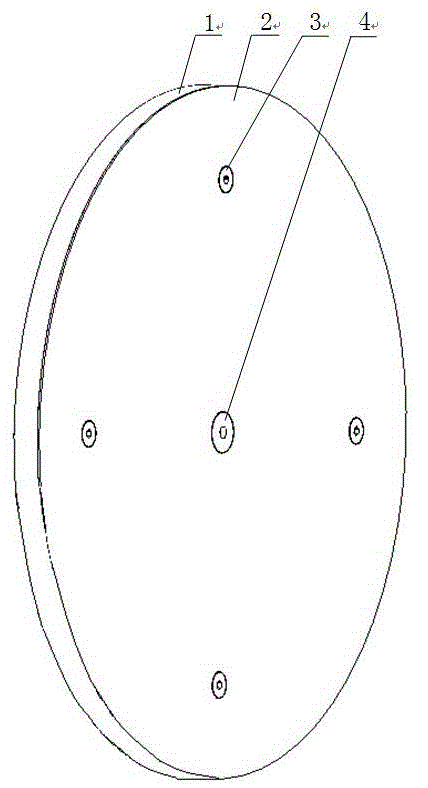

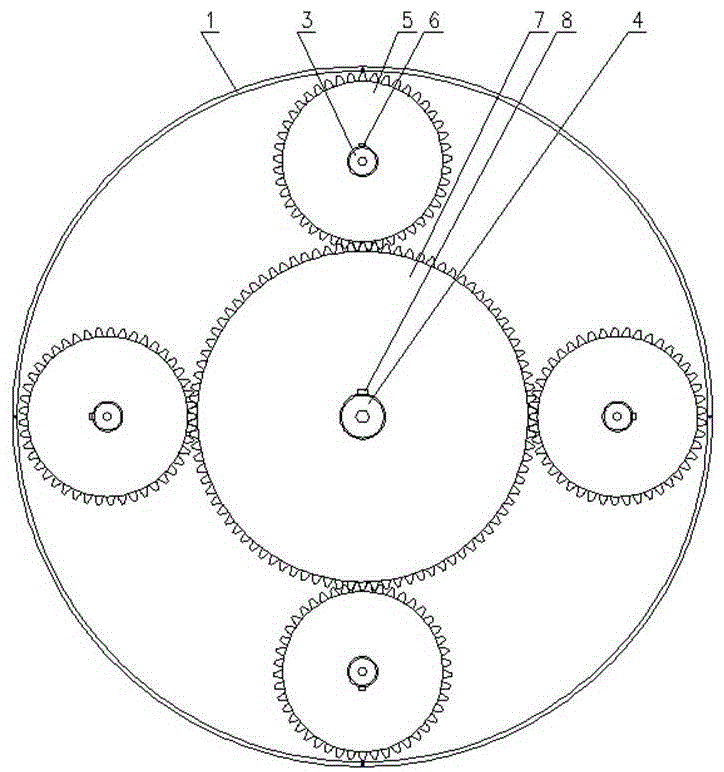

[0016] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a schematic diagram of the internal structure of the present invention after removing the end cap. exist figure 1 , figure 2 Among them, the device for applying tightening torque of the present invention includes a sun gear 7, four planetary gears 5 with the same diameter, a sun gear shaft 4, four planetary gear shafts 3, a flat key, and an end cover 2. Its connection relationship is that the center of the disc-shaped bracket 1 is provided with a sun gear shaft 4, and the periphery of the sun gear shaft 4 is evenly arranged with four planetary gear shafts 3, and the sun gear shaft 4 is provided with a sun gear flat key 8, and on the four planetary gear shafts 3 All are respectively provided with planetary wheel flat key 6. The sun gear 7 is mounted on the center of the disc-shaped bracket 1 through the sun gear shaft 4 , and the four planetary gears 5 are evenly di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com