A tensioned belt drive

A belt drive, belt tensioning technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of heavy weight, prone to failure, large volume, etc., to achieve compact structure, light weight, low speed The effect of no-load startup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

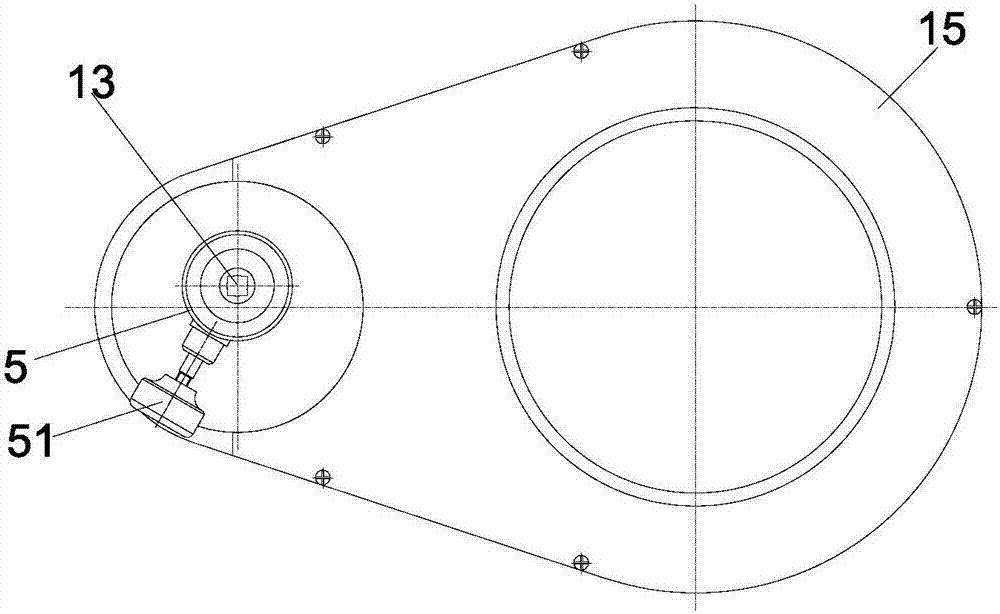

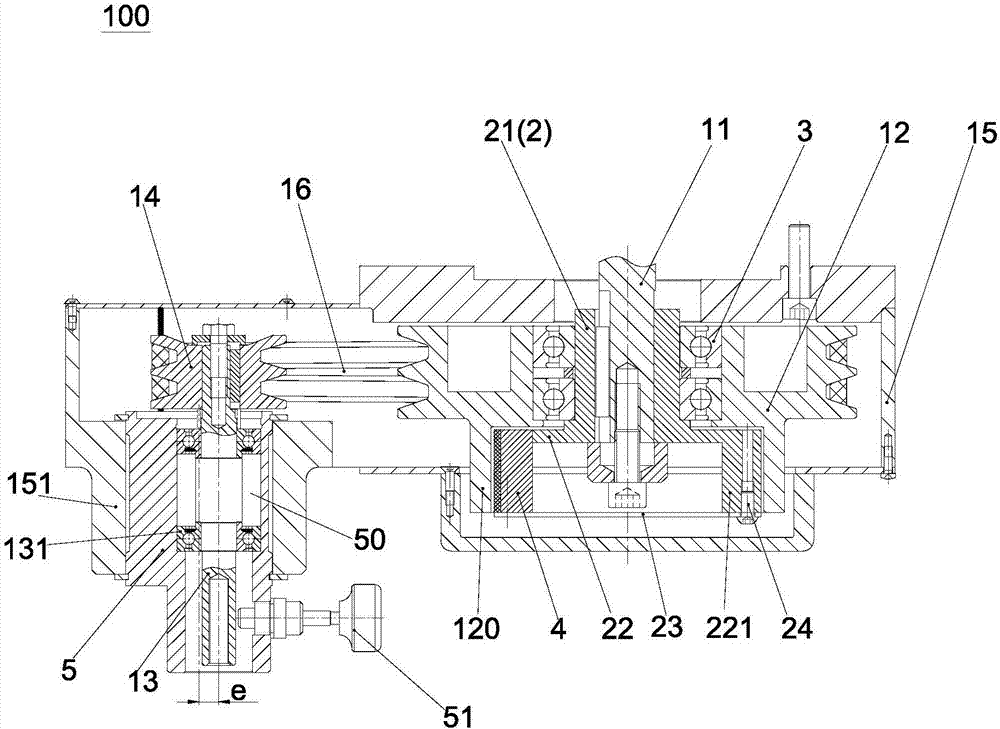

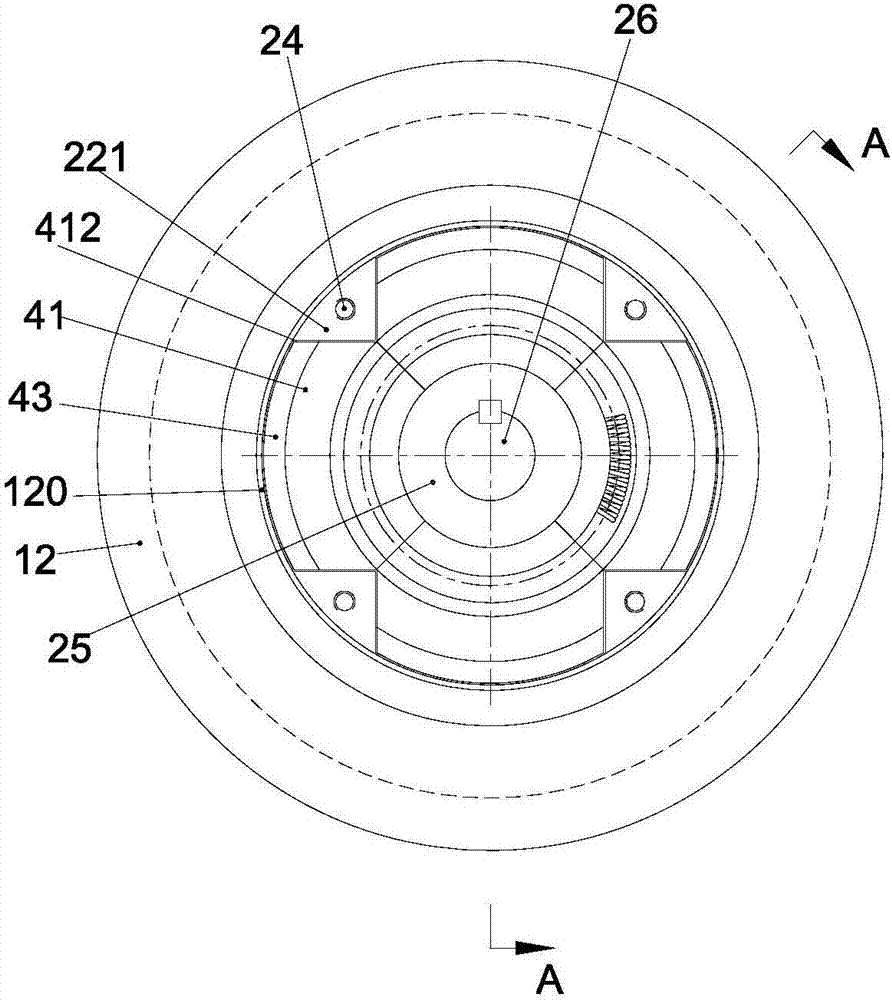

[0040] The present invention proposes a tensioned belt transmission device, which is provided with a driving shaft, a driving wheel, a driven shaft and a driven wheel, the driving wheel and the driven wheel are placed in a casing, and the front section is sleeved On the driving shaft, the driven wheel is sheathed and fixed on the front section of the driven shaft, and the driving wheel and the driven wheel are connected by a transmission belt. It is characterized in that the driving shaft and the driving A transmission disc is arranged between the wheels, the shaft sleeve at the front end of the transmission disc is sleeved and fixed on the drive shaft, the outer side of the shaft sleeve is sleeved with a driving wheel bearing, and the front section of the driving wheel is sleeved and fixed On the driving wheel bearing, a radially expandable clutch device is sheathed on the outer peripheral surface of the ring ear at the rear end of the transmission disc, and the clutch device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com