Water outburst and mud outburst testing device for high pressure-bearing tunnel

A test device and high pressure-bearing technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unsatisfactory and difficult to maintain pressure in the pressurized system, and achieve high pressure, good sealing, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

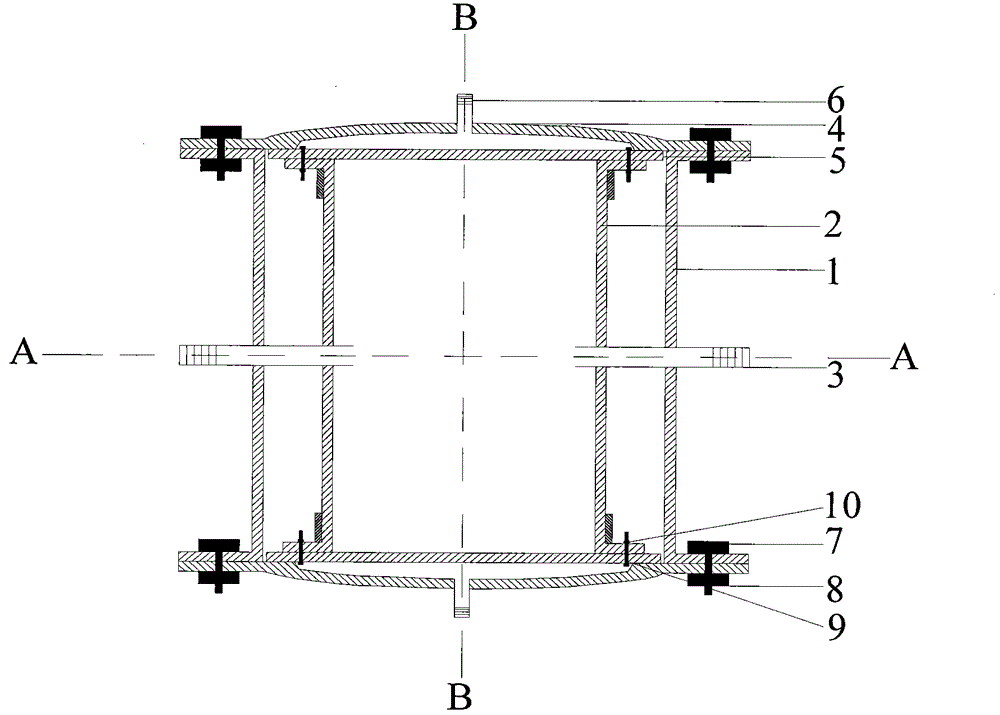

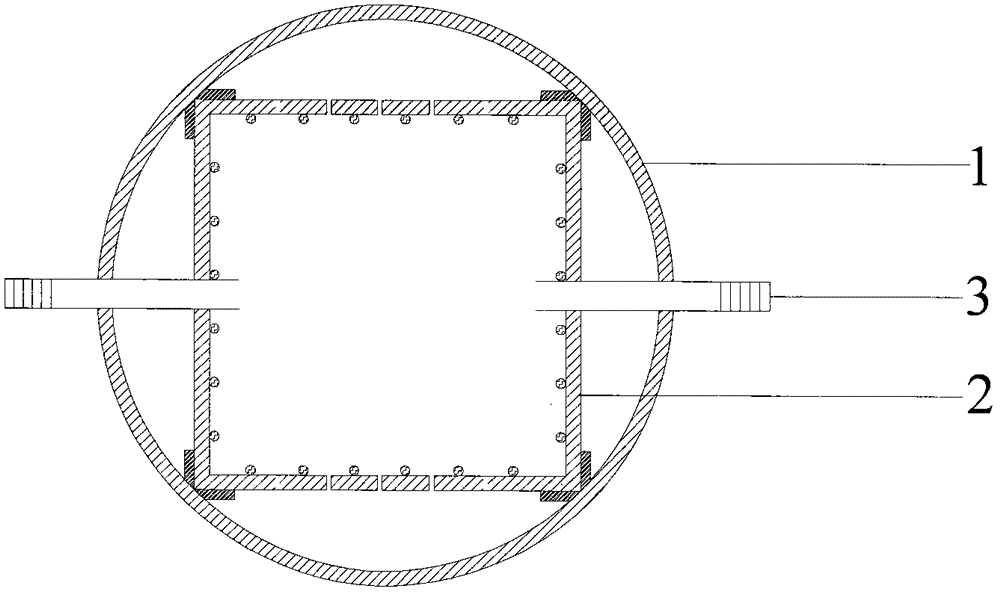

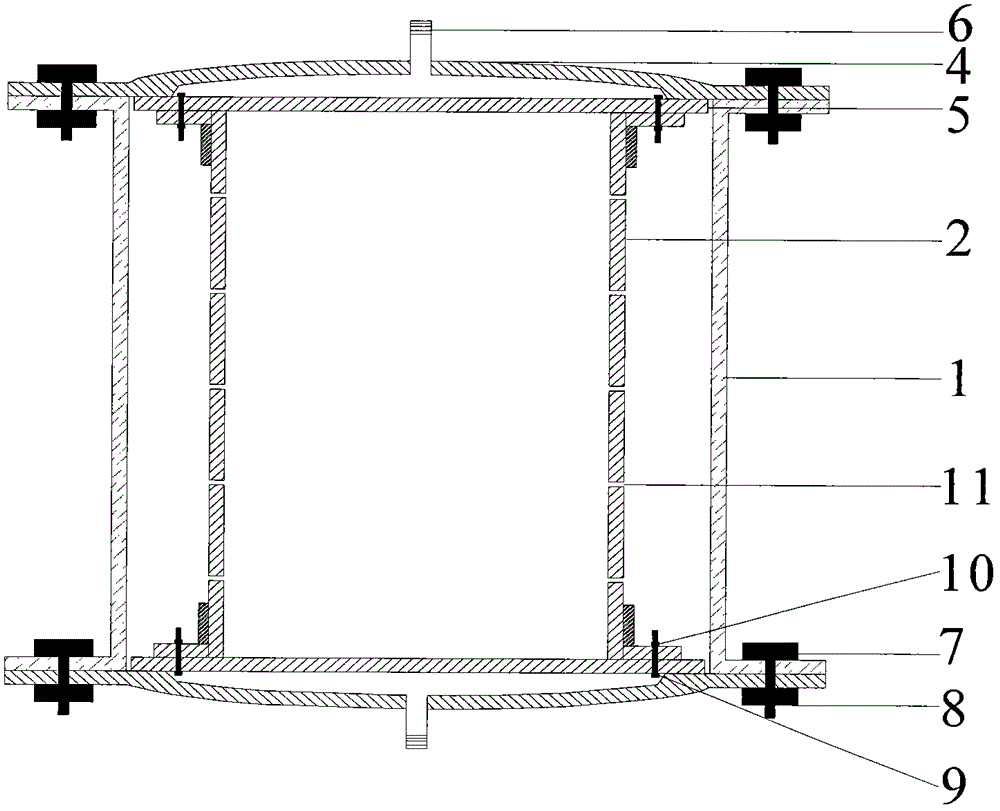

[0023] attached figure 1 It is the front view of the model test bench, with figure 2 And attached image 3 to attach figure 1 A-A and B-B sectional views. The pressure-bearing outer wall (1) is processed by high-strength thick seamless steel pipe, in a cylindrical shape, and the wall thickness is greater than 20mm. attached Figure 4 It is the front view of the inner shelter, and the inner shelter (2) is welded by high-strength thick steel plates, and uniformly distributed water inlet holes (9) are processed on the opposite side of the shelter. The tunnel opening (3) is made of steel pipe and welded with the pressure-bearing outer wall (1) and the inner shelter (2). The outer wall of the tunnel opening is processed with standard threads, which can be connected to high-pressure valves.

[0024] attached Figure 5 It is a top view of the outer wall cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com