Voice coil stretching molding machine

A molding machine, voice coil technology, applied in electrical components, sensors, etc., can solve the problems of high cost, low efficiency, uneven coil winding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

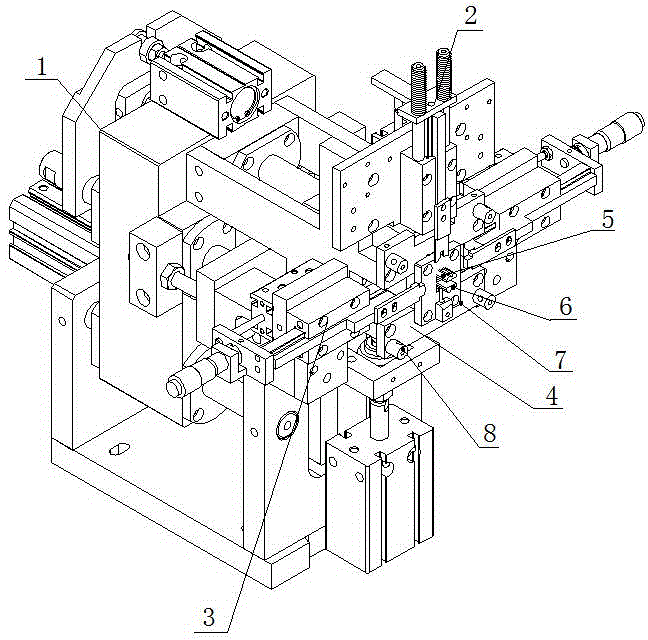

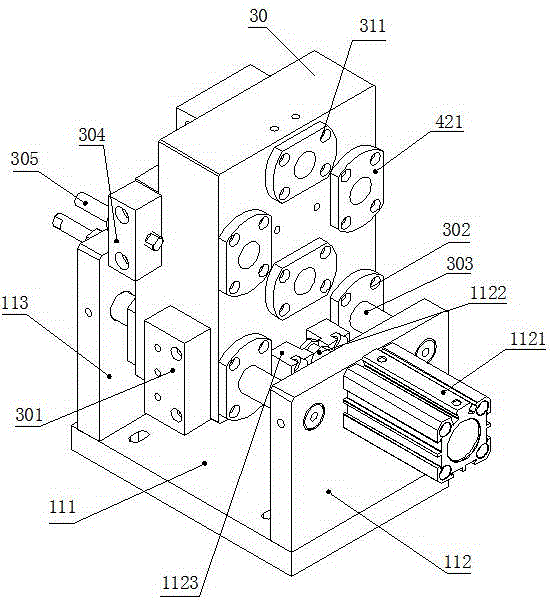

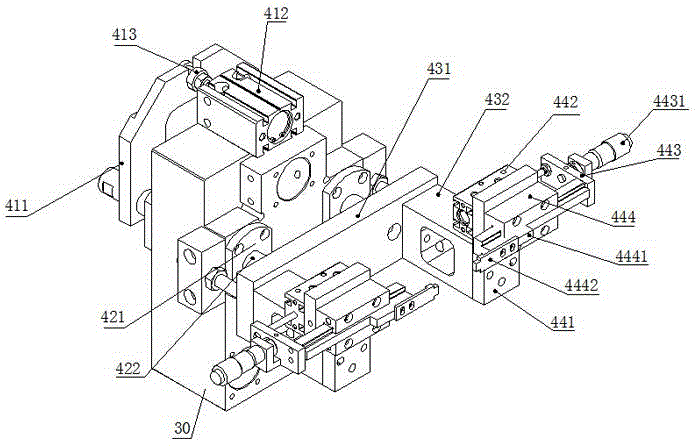

[0017] In this example, if Figure 1 to Figure 5 As shown, a voice coil stretching molding machine of the present invention includes a voice coil stretching base 1 that can be moved back and forth and stretched, and a voice coil stretching core pulling mechanism 4 connected to the voice coil stretching base 1 , and the voice coil stretching and pressing mechanism 2 connected to the upper end of the voice coil stretching core pulling mechanism 4, and the voice coil stretching shaping mechanism 3 connected to the two ends of the voice coil stretching core pulling mechanism 4, And the stretching block 7 installed and connected with the voice coil stretching core pulling mechanism 4, and the upper stretching fixture 5 arranged at the center of the stretching block 7, and the lower stretching fixture 6 arranged below the upper stretching fixture 5; The voice coil stretching and shaping mechanism 3 is connected with the voice coil stretching core pulling mechanism 4 and is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com