Crash sensor and intelligent dust collector robot

A technology of collision sensor and robot body, which is applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc., to achieve the effect of sensitive collision detection, simple structure, random installation position and fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

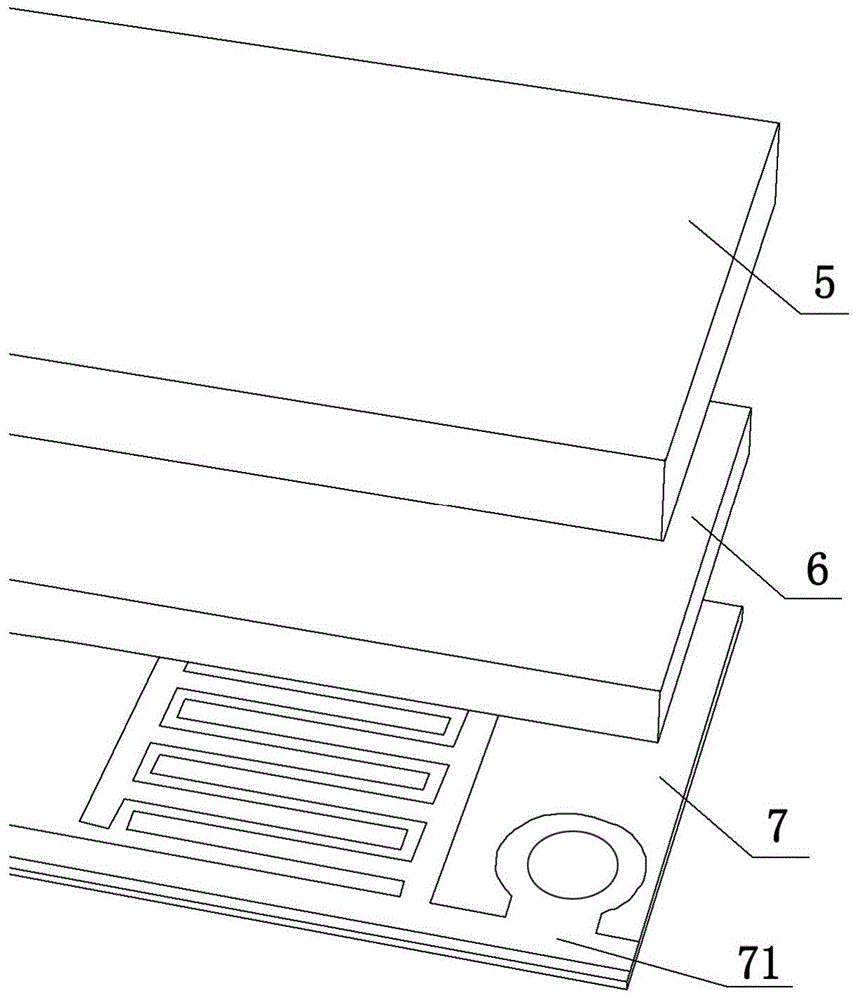

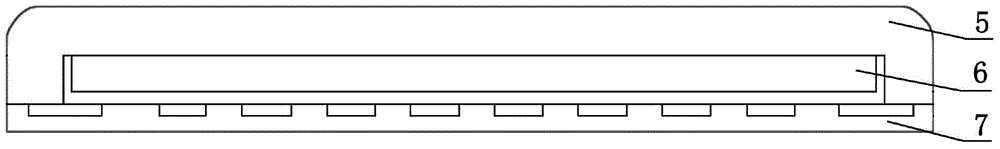

[0022] The basic structure of a collision sensor provided by the embodiment of the present invention consists of three parts, such as figure 2 As shown, from the outer layer to the inner layer are ordinary rubber 5 , conductive rubber 6 and flexible circuit board 7 . The flexible circuit board 7 is provided with two independent conductive loops 71 , one side of the conductive rubber 6 is fixed on the ordinary rubber 5 , and the other side of the conductive rubber 6 faces the flexible circuit board 7 .

[0023] Ordinary rubber 5 is used as a buffer part in contact with obstacles during a collision, and its shape is designed to be a smooth shape, such as image 3 As shown, the edges and corners of the outer surface have smooth chamfers, which are beautiful and will not damage other objects in the event of a collision. A groove is designed in the middle of the inner surface of the ordinary rubber 5 for fixing the conductive rubber 6 . The guide rubber 6 is used as a conductive...

Embodiment 2

[0027] The present invention can be applied to intelligent vacuum cleaner robots, replacing the traditional form of detecting collisions through micro switches.

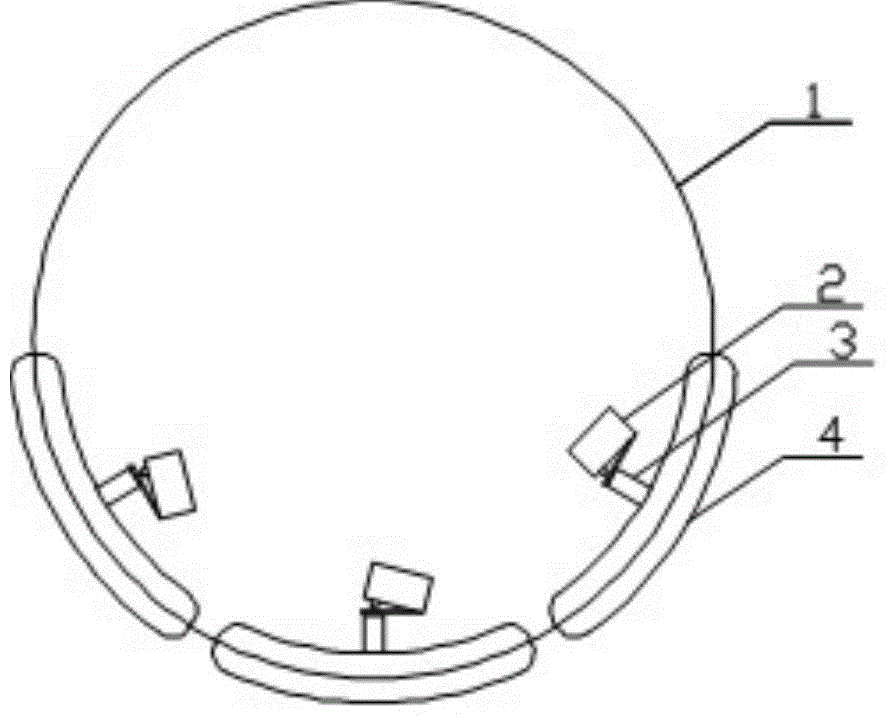

[0028] Such as Image 6 As shown, an intelligent vacuum cleaner robot provided by an embodiment of the present invention includes a robot body 91 and a plurality of collision sensors 92 . The robot body 91 is a cylinder, and the plurality of collision sensors 92 are installed around the side of the robot body.

[0029] In the embodiment of the present invention, six collision sensors 92 are installed around the robot body 91 , so that when the intelligent vacuum cleaner robot collides with an obstacle, it can make a corresponding response by distinguishing the location of the collision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com