Tissue engineered nerve graft with suspension fiber scaffold and preparation method thereof

A fibrous scaffold and tissue engineering technology, applied in the fields of medicine and biomedical engineering, can solve the problems such as the difficulty of uniform distribution of microfilaments, the limited effect of directional guidance, and the influence of treatment effects, so as to improve the success rate, low cost, avoid Effects of immune tissue response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

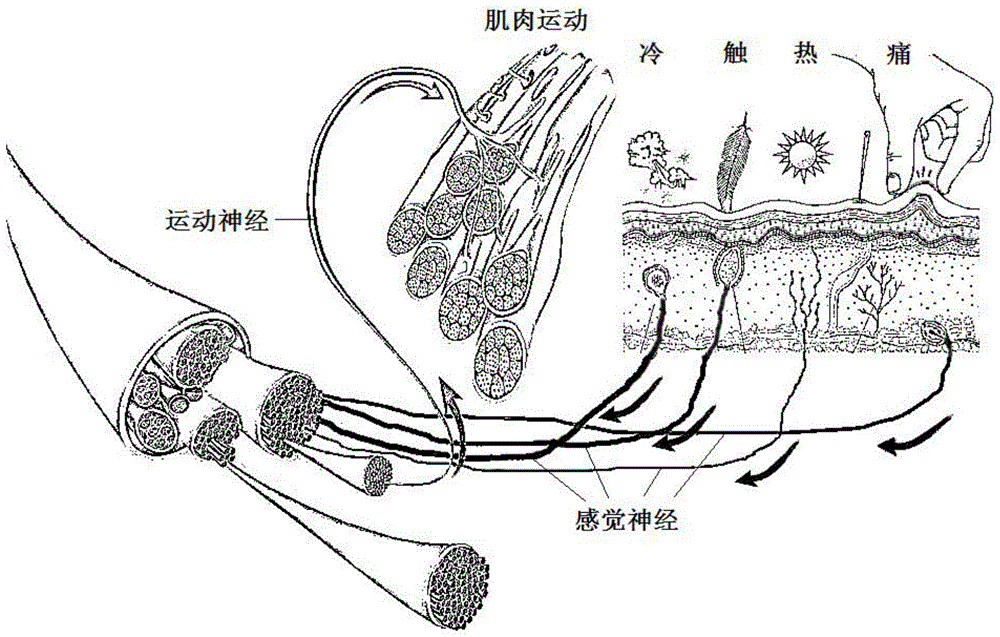

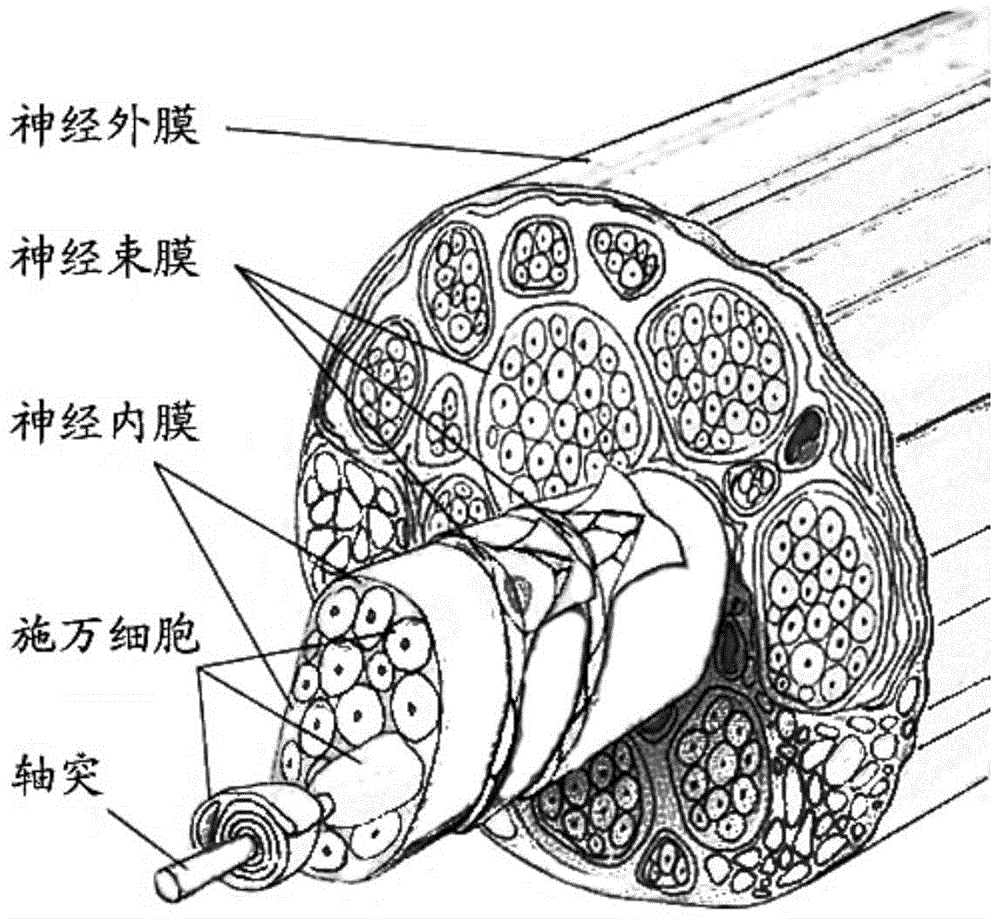

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) the benzoic acid solution 50ml (benzoic acid solution concentration of 0.1mol / L) of preparation 3% polylactic acid is contained in the ink cartridge that model is HP51626A;

[0053] (2) Adjust the printer nozzle needle diameter to 2μm, the number of needles to 4, the distance from the nozzle to the bottom layer to 10mm, and the booster pulse frequency to 1v;

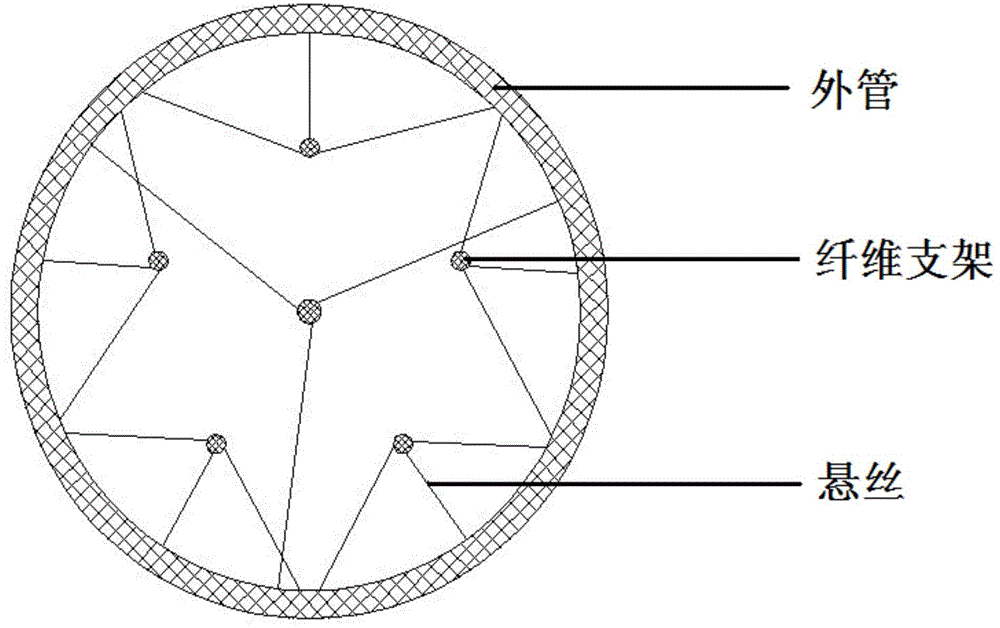

[0054] (3) Accurately simulate the three-dimensional spatial structure of different nerves, compile corresponding control programs, preset the three-dimensional model of the printer, and design the shape of tissue-engineered nerve grafts: tissue-engineered nerve grafts include catheters and intratube fiber scaffolds, such as image 3 , Figure 4 As shown, each fiber support is provided with a number of suspension wires along the fiber length direction to connect with the inner wall of the catheter, and the fiber support is suspended in the catheter through the distribution of suspension wires. The connection ...

Embodiment 2

[0062] (1) 50ml of citric acid solution (concentration of citric acid solution is 0.05mol / L) of preparing 5% sodium alginate is contained in the ink cartridge that model is HP51626A;

[0063] (2) Adjust the printer nozzle needle diameter to 100 μm, the number of needles to 16, the distance from the nozzle to the bottom layer to 25mm, and the booster pulse frequency to 15v;

[0064] (3) Accurately simulate the three-dimensional spatial structure of different nerves, compile corresponding control programs, preset the three-dimensional model of the printer, and design the shape of tissue-engineered nerve grafts: tissue-engineered nerve grafts include catheters and intratube fiber scaffolds, such as image 3 , Figure 4As shown, each fiber support is provided with a number of suspension wires along the fiber length direction to connect with the inner wall of the catheter, and the fiber support is suspended in the catheter through the distribution of suspension wires. The connecti...

Embodiment 3

[0072] (1) 50ml of acetic acid solution (concentration of acetic acid solution is 0.1mol / L) of preparing 5% chitosan is contained in the ink cartridge that model is HP51626A;

[0073] (2) Adjust the printer nozzle needle diameter to 50 μm, the number of needles to 9, the distance from the nozzle to the bottom layer to 40mm, and the booster pulse frequency to 10v;

[0074] (3) Accurately simulate the three-dimensional spatial structure of different nerves, compile corresponding control programs, preset the three-dimensional model of the printer, and design the shape of tissue-engineered nerve grafts: tissue-engineered nerve grafts include catheters and intratube fiber scaffolds, such as image 3 , Figure 4 As shown, each fiber support is provided with a number of suspension wires along the fiber length direction to connect with the inner wall of the catheter, and the fiber support is suspended in the catheter through the distribution of suspension wires. The connection positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com