A passive automatic detection system and detection method for a mixing production line

An automatic detection and production line technology, applied in mixer accessories, chemical instruments and methods, dissolution and other directions, can solve the problems of affecting production line work, short service life, waste of manpower and material resources, etc., to improve the level of industrial automation, overcome manpower and material resources. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

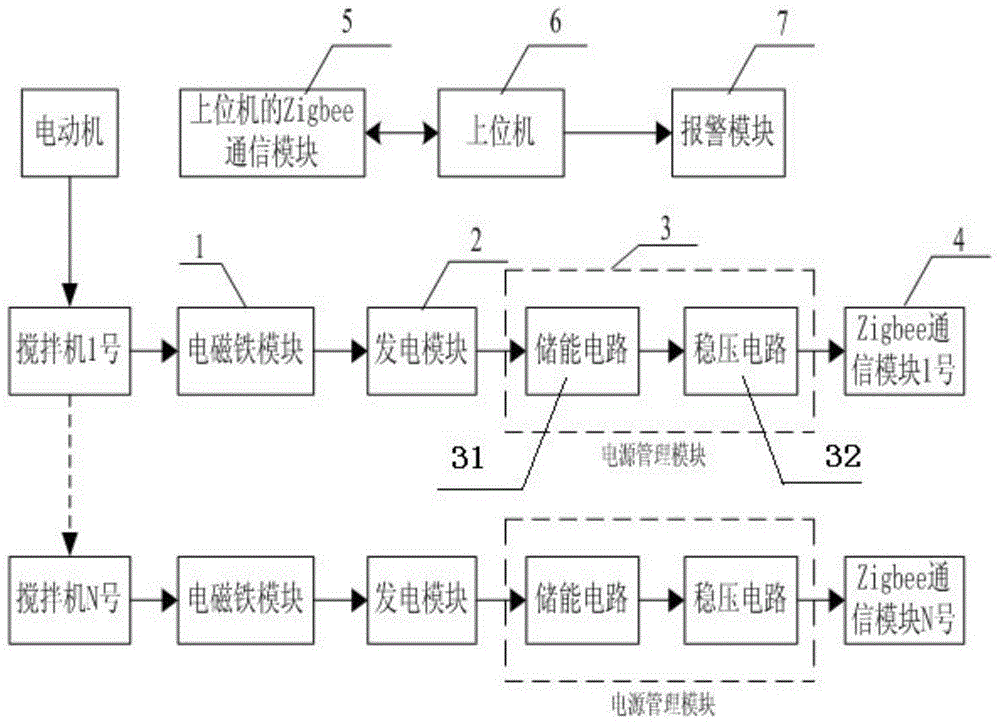

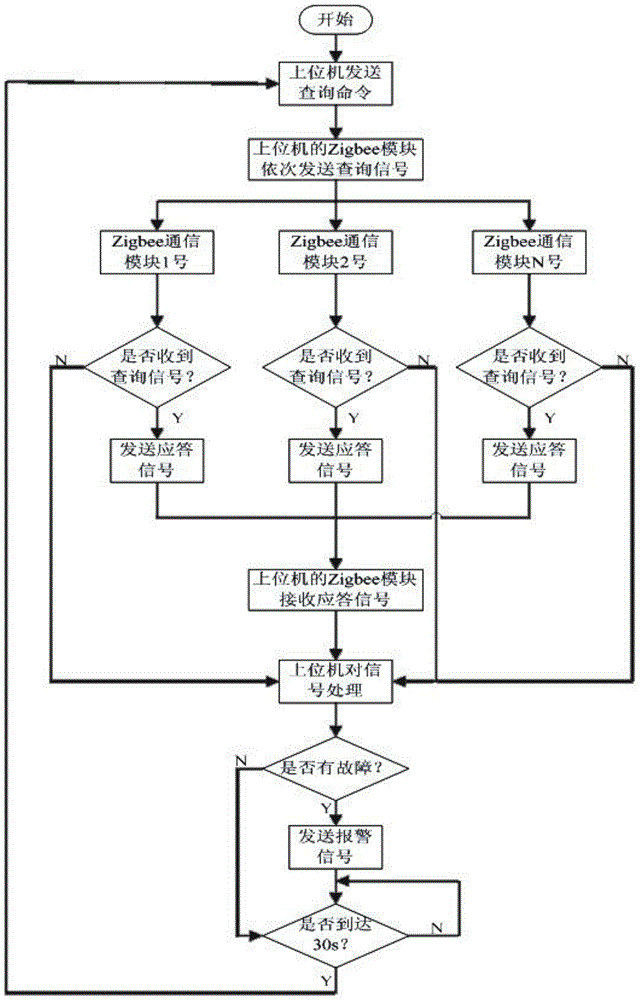

[0042] Such as figure 1 with 2 As shown, a passive automatic detection system for a mixing production line includes multiple sets of signal detection devices, an upper computer communication module 5, an upper computer 6 and an alarm module 7. Each group of signal detection devices includes an electromagnet module 1, a power generation module 2. Power management module 3 and lower computer communication module 4.

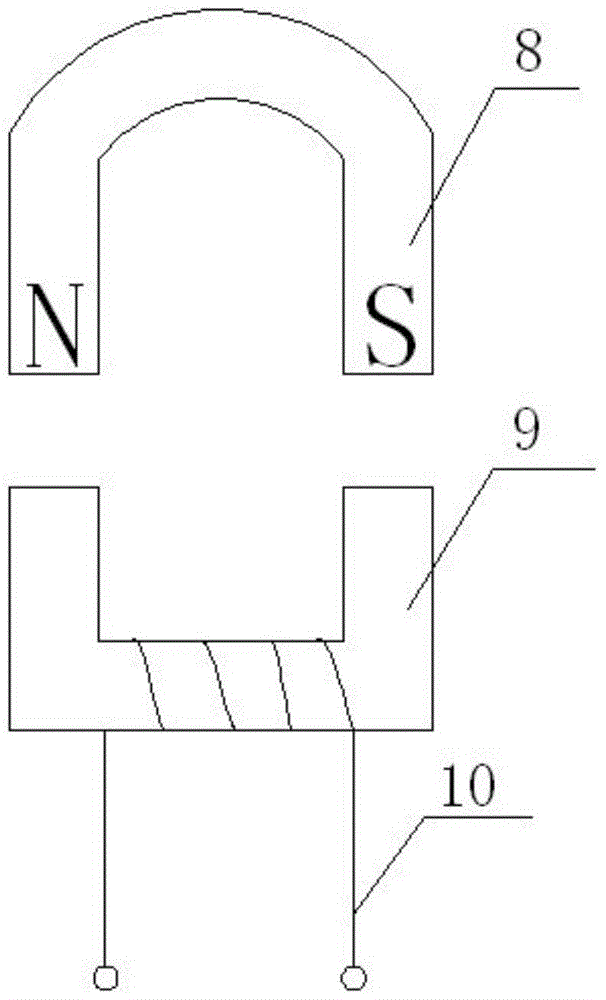

[0043] The electromagnet module 1 is installed on a bearing of a mixer, and is used to rotate with the rotation of the mixer, and a changing magnetic field is generated during the rotation;

[0044] The power generation module 2 is fixed in the changing magnetic field, and is used to generate a voltage through the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com