A kind of forging mold and forging method

A mold and model technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of poor tissue mechanical properties, low production efficiency, cutting of metal flow lines, etc., and achieve shortening Effects of forging cycle, improved utilization rate, and small margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

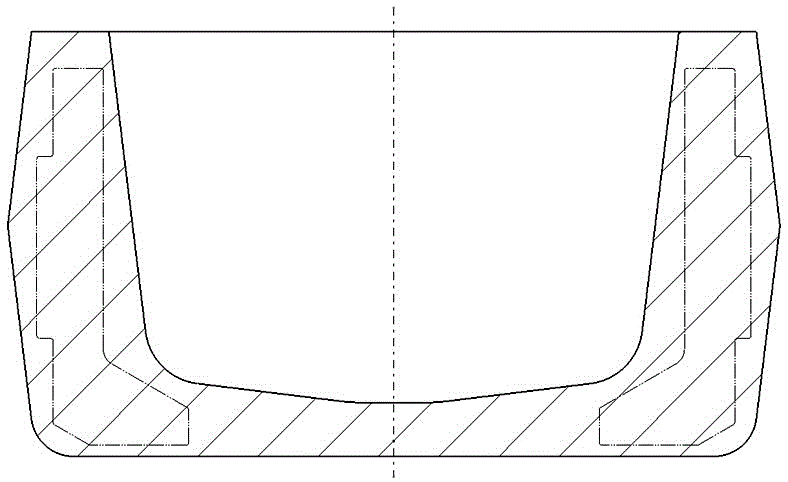

[0028] refer to figure 1 , figure 1 The large deep cylindrical forging shown in is processed by conventional die forging in the prior art, figure 1 The dotted line in is the rough machined part further processed from the forging. The flow line of the forging is not ideal, and the metal flow line will be cut off during the machining process; moreover, the side walls of the forging have a large draft angle, the forging allowance is large, and the material utilization rate during processing is low.

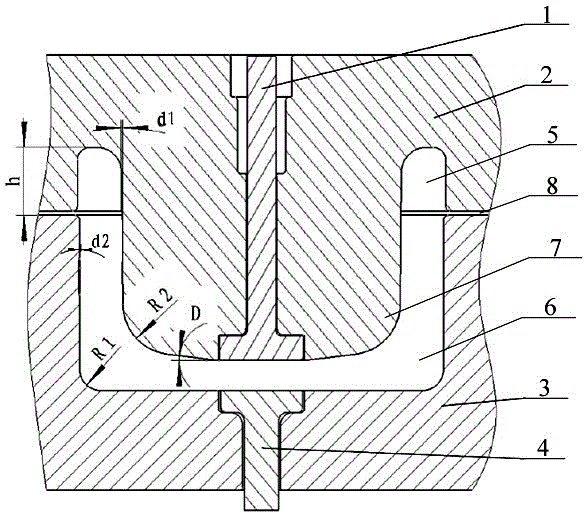

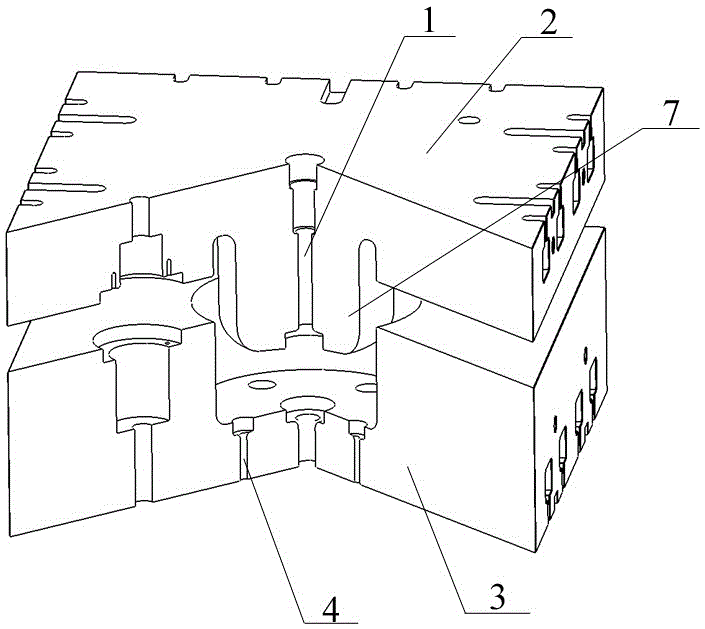

[0029] refer to figure 2 and image 3 , the embodiment of the present invention provides a forging die, which is generally used for the processing of large deep cylindrical forgings, including an upper die 2 and a lower die 3 that match ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com