A method of processing wood with a tapered cylinder tool

The technology of a conical cylinder and tool is applied in the field of processing wood by using a turning conical cylinder tool, which can solve the problems such as material can not be reused, material waste processing cost, etc., so as to increase the utilization rate, reduce the processing cost, and increase the friction force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

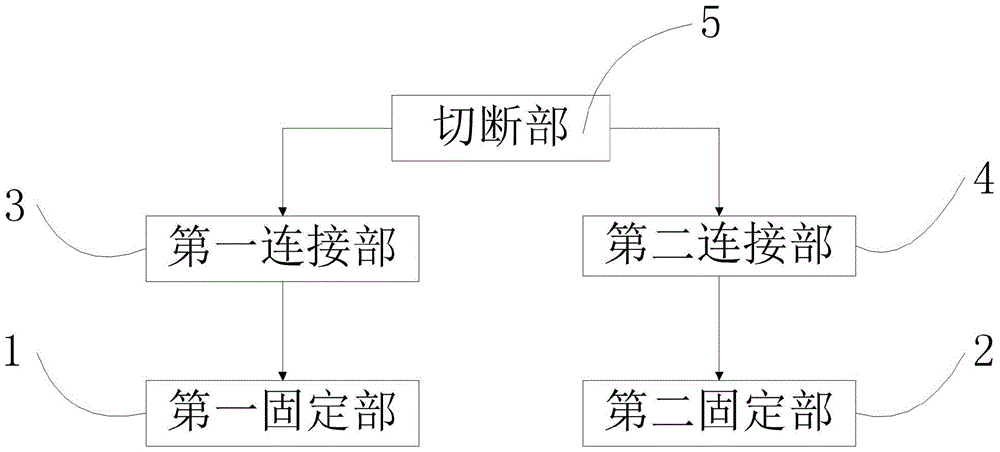

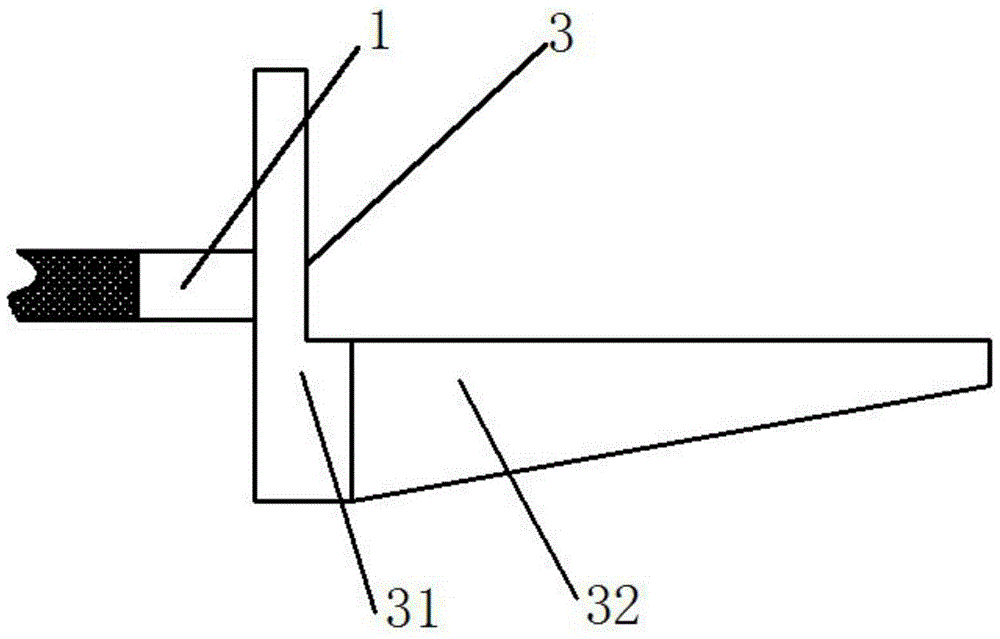

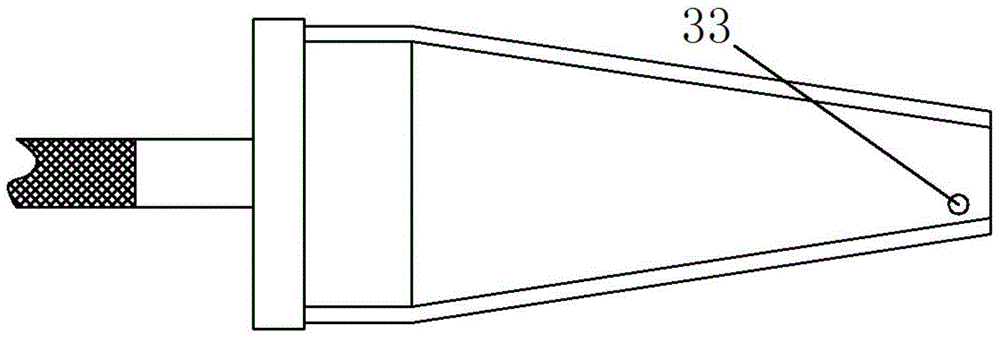

[0044] refer to figure 2 Shown, it is the left front view of Embodiment 1 in the car tapered cylinder tool of the present invention; image 3 As shown, it is the left top view of Embodiment 1 in the car tapered cylinder tool of the present invention; and Figure 4As shown, it is the left isometric view of Embodiment 1 of the conical cylindrical tool of the present invention; the difference between this embodiment and the above-mentioned conical cylindrical tool is that the first fixing part 1 is a cylinder, one end of the cylinder is connected to the first connecting part 3, and the surface of the other end has a layer of knurling, and the knurling is used to increase the distance between the fixed part and the lathe The friction force between the fixed frames makes the fixed part more firmly inserted in the fixed frame of the lathe, the first connecting part 3 is a stepped curved surface, and the stepped curved surface includes the first The stepped portion 31 and the seco...

Embodiment 2

[0050] refer to Figure 6 As shown, it is the left isometric view of Embodiment 2 in the conical cylindrical tool of the present invention; the difference between this embodiment and the above-mentioned conical cylindrical tool is that the first The connecting portion 3 is a square prism, and the tapered cylindrical tool of the car also includes a first cutting portion 6, and the first cutting portion 6 is connected with the first connecting portion 3 for use in the described first cutting portion 6. A tapered notch is cut on the inside of the wood, and the circular hole 33 is installed on the cutting part.

[0051] When using the tool, at first the first fixed part 1 is installed on the fixed frame of the lathe, the wood is installed on the other side of the lathe, and the first cutting part 6 Form a certain cutting angle with the wood, then start the lathe to cut, form the tapered notch on the inner side of the wood, then open the distance between the cutting part and the w...

Embodiment 3

[0053] refer to Figure 7 As shown, it is an axonometric view of the left fixing part in Embodiment 3 of the tapered cylinder tool of the present invention; Figure 8 As shown, it is the front view of the left connecting part in Embodiment 3 in the car tapered cylinder tool of the present invention; and Figure 9 As shown, it is a top view of the left connecting part in Embodiment 3 of the tapered cylindrical tool of the present invention; the difference between this embodiment and the above-mentioned tapered cylindrical tool is that the first The fixing part 1 and the first connecting part 3 are connected by threads, the first fixing part 1 is a cylinder, one end of the cylinder has an internal thread, and one end of the first connecting part 3 has a The protrusion has an external thread, and the other end is an arched square cylinder. One side of the outer surface of the arched square cylinder is a plane, and the corresponding side is a smooth concave surface. There is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com