Air duct for concrete aggregate silo

A concrete aggregate and air duct technology, which is applied in the field of air ducts, can solve the problems such as the difficulty of achieving heat exchange effect in the wind field, and achieve the effects of significant heat exchange effect, reduced wind resistance, and uniform wind flow field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

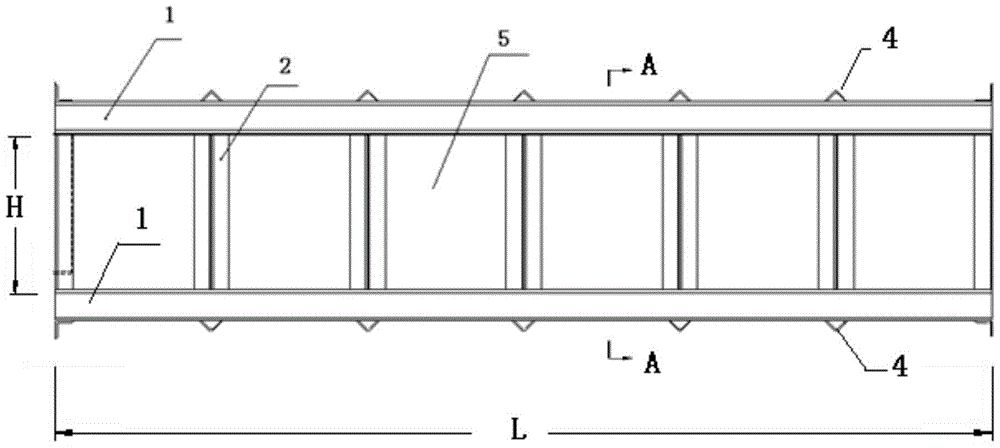

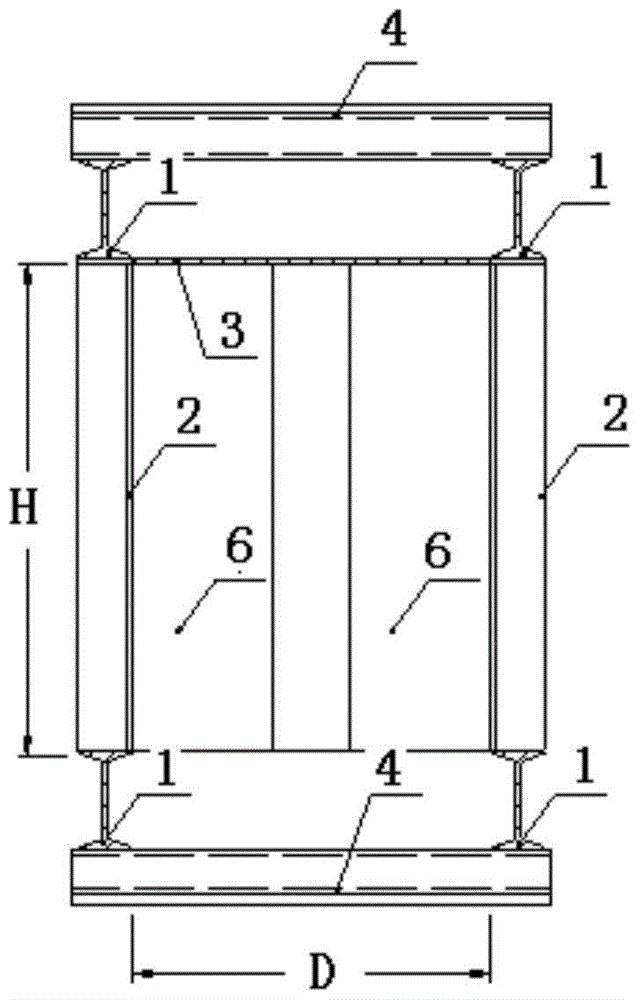

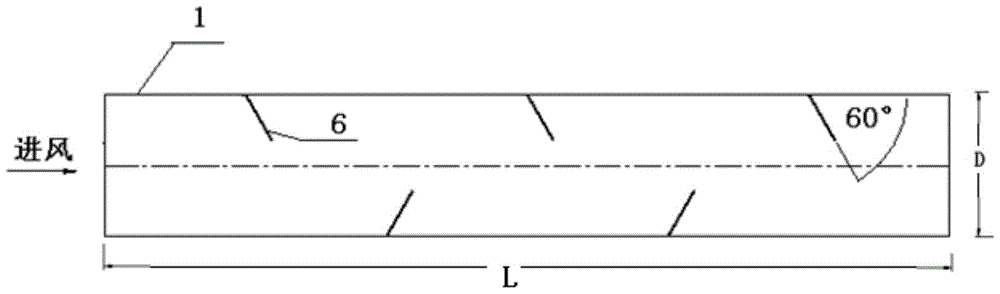

[0023] Embodiment 1, a kind of air duct for concrete aggregate silo, see figure 1 , figure 2 with image 3 , with the rectangular frame as the skeleton of the air duct, the size of the air duct (that is, the internal dimension of the rectangular frame) is L (length) × D (width) × H (height) = 6m × 1m × 1.2m. The inner two sides of the rectangular frame are provided with deflectors 6 obliquely at intervals along the direction of the wind, there is a gap between the two rows of deflectors 6, louvers 5 are arranged between the vertical stiffeners 2 of the rectangular frame, and the top surface of the rectangular frame is provided with There is a top plate 3, the bottom surface is not closed.

[0024] see Figure 7 , the plane size of the silo is a (length) × b (width) = 6m × 4m (b is not marked in the figure); during the operation of the silo, the air duct is always buried in the aggregate, and the bottom surface is formed by accumulation of aggregate. The cross-section of ...

Embodiment 2

[0027] Example 2, see figure 2 , on the basis of Embodiment 1, in order to ensure that the air duct is sufficient to withstand the impact force and lateral pressure caused by the slow decline of the aggregate in the silo, the rectangular frame of this embodiment is composed of four main beams 1 and the gap between the main beams 1 The vertical stiffeners 2 and transverse stiffeners 4 are formed. The vertical stiffeners 2 are spaced between the upper and lower sides of the main beam 1, and the transverse stiffeners 4 are spaced between the upper two outer sides and the lower two outer sides of the main beam 1.

[0028] In order to further improve the rigidity of the air duct, the main girder 1 is made of I-beam, the vertical stiffener 2 is made of double-angle steel with a distance of 1m, and the transverse stiffener 4 is made of single-angle steel with a distance of 1m. The steel types selected for main girder 1, vertical stiffener 2, and transverse stiffener 4 should be dete...

Embodiment 3

[0029] Example 3, see Figure 4 , The air duct of the present invention is buried in the silo, and the particle size range of the finished aggregate in hydropower projects is 150mm-80mm, 80mm-40mm, 40mm-20mm, and 20mm-5mm. On the basis of Examples 1 and 2, for the aggregates in the silo with aggregate particle sizes of 150mm-80mm, 80mm-40mm, and 40mm-20mm, air outlet holes 7 are evenly arranged on the top plate 3 . In this embodiment, the air outlet holes 7 are circular, with a diameter of ф10, arranged in a quincunx shape, with a pitch of 100 mm and a row pitch of 100 mm, and the row pitch is staggered.

[0030] An air outlet hole 7 with a diameter of ф10 is set on the top plate 3, arranged in a quincunx shape, which can prevent large-grained aggregates from falling into the air duct, and the wind can diffuse upwards into the silo through the air outlet hole 7.

[0031] For aggregates with a particle size of 20mm ~ 5mm, no air outlet 7 is provided on the top plate to prevent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com