Oversize storage tank construction platform system and forward-erection construction method thereof

A construction platform and extra-large technology, applied in the direction of floating buildings, etc., can solve the problems of unfavorable large plate installation, long construction period, slow lifting of floating plate, etc., to shorten construction period, save measures and materials, and strengthen welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

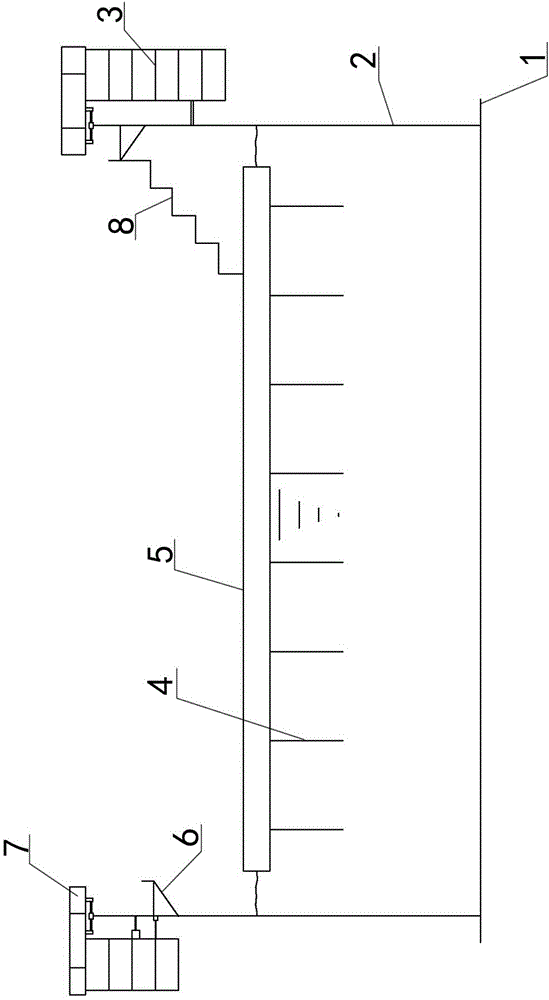

[0041] The embodiment is a storage tank with a single volume equal to 100,000 cubic meters. Its structure is a vertical storage tank with a double-disk outer floating roof in the cabin. The diameter of the tank is Φ80m, the height of the tank is 21.97m, and the total weight of the tank is 2062 tons. The floating roof weighs 476 tons, and the tank wall has nine rings of panels.

[0042] see figure 1As shown, the construction platform system of this extra-large storage tank includes the installed floating roof 5 of the storage tank and the construction platform used in conjunction with it and fixed on the tank wall plate 2, the two are connected by a ladder 8, and the construction The platform is divided into inner and outer sides of the tank body, including a cantilever support platform 6 inside the tank body and wall-attached sliding frames 3 distributed on the outside of the tank body at intervals.

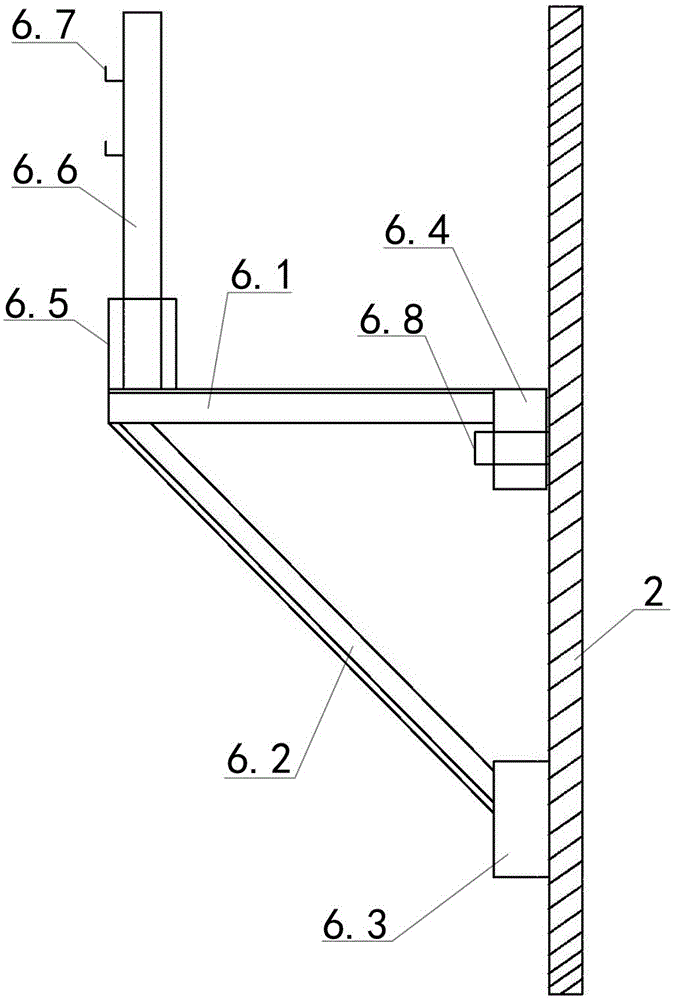

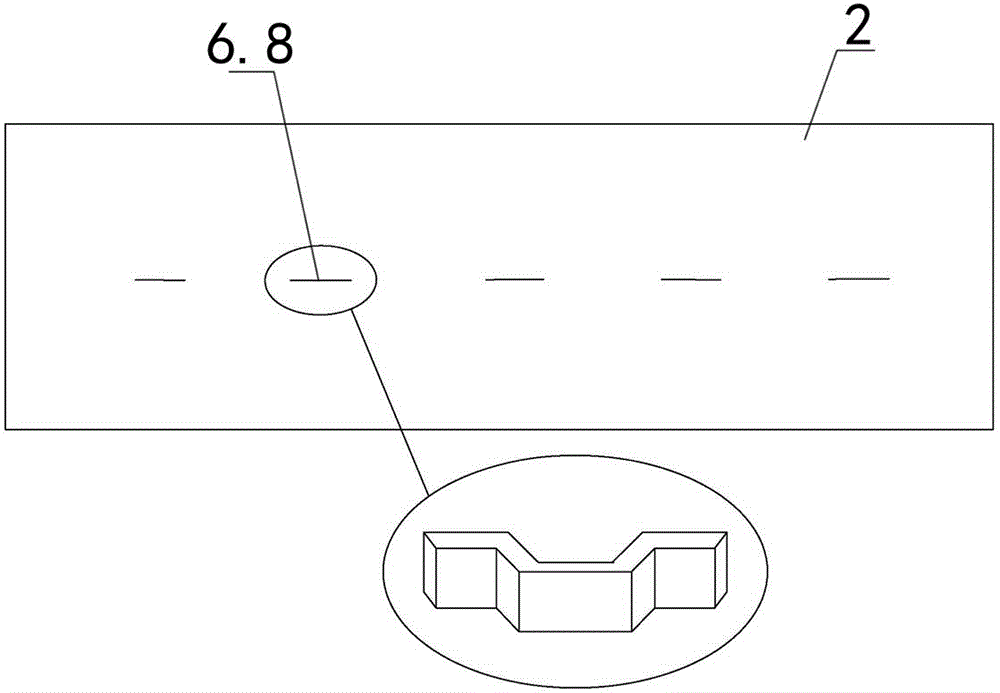

[0043] see Figure 2~3 As shown, a cantilever support platform temporarily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com