Elevator suspension rope tension measurement and adjustment mechanism

An adjustment mechanism and suspension rope technology, applied in the direction of lifts, transportation and packaging, etc., can solve the problems of inconvenient measurement and adjustment, complex structure, etc., and achieve the effects of convenient and quick adjustment, accurate output pressure, and economical production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

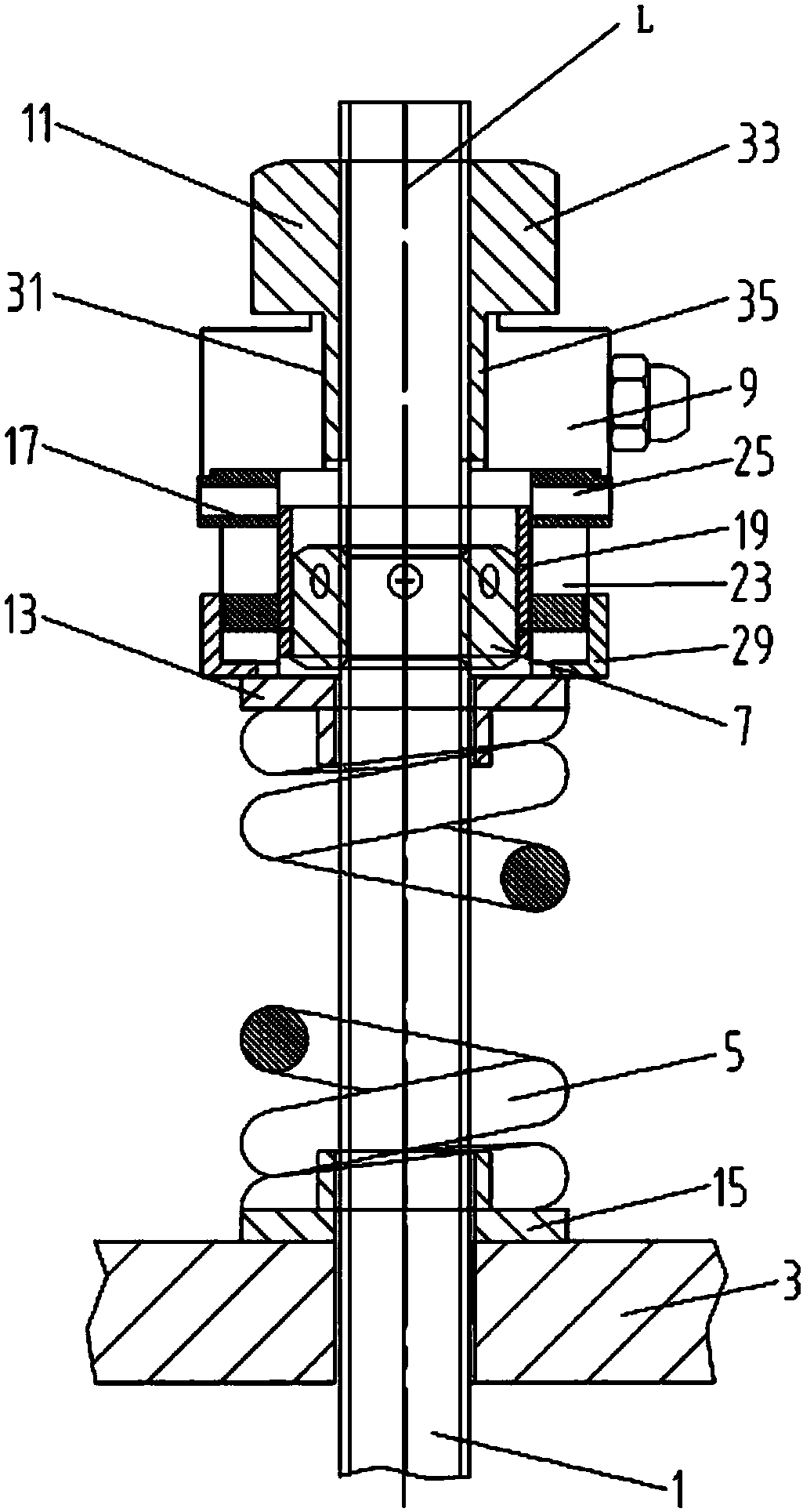

[0028] refer to figure 1 , an elevator suspension rope tension measurement and adjustment mechanism, including a screw 1, a rope seat 3, an elastic element 5, a lock nut 7, a pressure sensor 9 and an adjustment nut 11.

[0029] Above-mentioned screw rod 1, rope head seat 3 and elastic element 5 are the existing structures of the elevator, wherein the lower end of screw rod 1 is connected to the elevator suspension rope (not shown), the rope head seat 3 is threadedly set on the screw rod 1, and the elastic element 5 It is a compression spring, which is sleeved on the screw rod 1 and located above the rope end seat 3 . The upper and lower ends of the elastic element 5 are provided with upper and lower spring pads 13 , 15 sheathed on the screw rod 1 , wherein the lower spring pad 15 is arranged between the elastic element 5 and the rope end seat 3 .

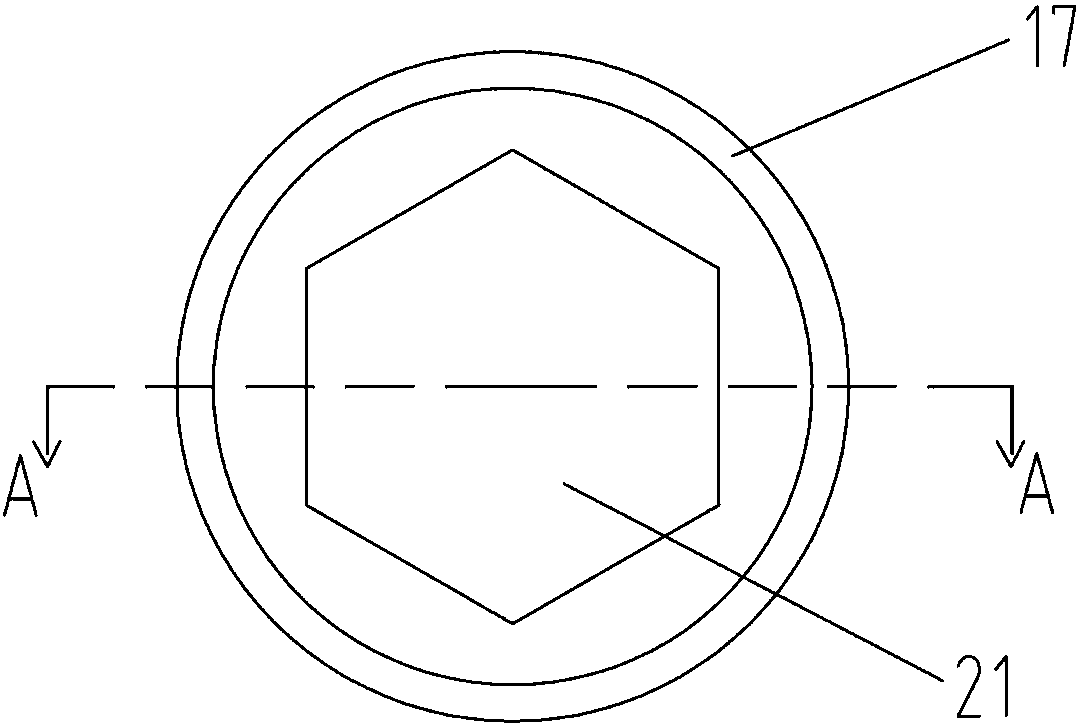

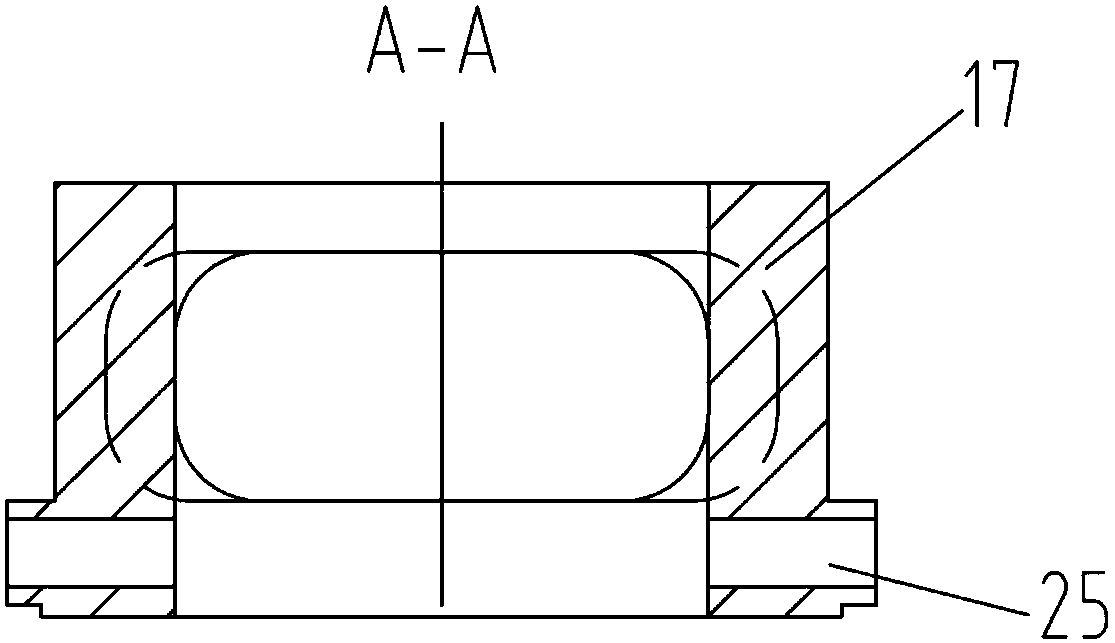

[0030] further reference figure 2 with Figure 5 , the lock nut 7 is threadedly connected to the screw rod 1 , and an adjuster...

Embodiment 2

[0035] further reference Figure 8 with Figure 9 Compared with Embodiment 1, the tension measurement and adjustment mechanism of this embodiment is only slightly different in shape from the regulator 40 and the regulator 17 of the first embodiment, so only the regulator 40 is explained and omitted. Description of the remaining components.

[0036]The above-mentioned regulator 40 is roughly in the shape of a hollow cylinder, and a section of arc edge is cut along its axial direction, thus forming a cylinder 42 , an irregular inner cavity 44 and a single adjustment window 46 . Likewise, its top end is provided with a plurality of adjustment holes 48 along its periphery. In this way, the adjuster 40 can also achieve the adjustment of the locking nut by opening an adjustment window 46 . Moreover, the adjuster 40 of this embodiment does not need to be sleeved down from the upper end of the screw rod 1 during assembly, and only needs to install the adjuster 40 from the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com