Vaporizer, white carbon black production apparatus and white carbon black production method

A vaporizer and white carbon black technology, applied in the direction of silicon oxide, silicon dioxide, silicon halide compounds, etc., can solve the problems of large fluctuations in the specific surface area of white carbon black and reduce the quality of white carbon black

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

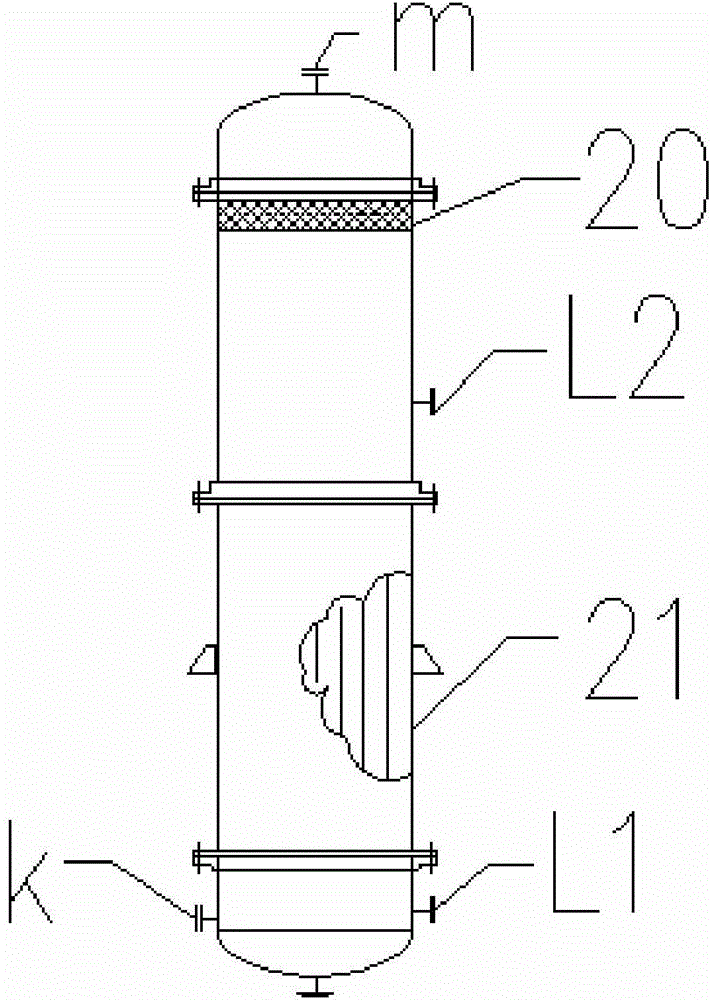

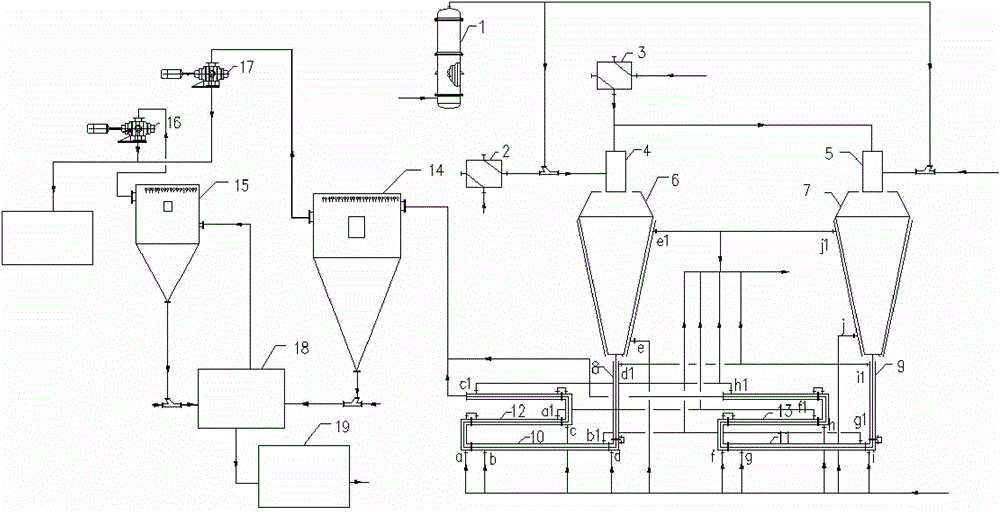

[0118] The molar ratio is methyltrichlorosilane: air: hydrogen = 1:10:1 ratio, methyltrichlorosilane is vaporized through vaporizer 1, and the liquid level of the vaporizer is controlled by a regulating valve to keep it stable so that the liquid level is higher than that of the tube The upper surface is 30mm; the vaporized methyltrichlorosilane gas phase is mixed with the air from the air heater 2, and then mixed with the hydrogen from the hydrogen heater 3 in the first reactor 4 and the second reactor 5 and injected into the The high temperature hydrolysis reaction is carried out in the corresponding first synthesis furnace 6 and the second synthesis furnace 7 . The gas-solid mixture discharged from the first synthesis furnace 6 and the second synthesis furnace 7 is cooled through the first vertical pipe 8 and the second vertical pipe 9, the first horizontal pipe 10 and the second horizontal pipe 11, and the cooled material is respectively The agglomerated white carbon black ...

Embodiment 2

[0125] The technical solution of Example 1 was used to produce white carbon black. The difference was that in this example, the molar ratio of methyltrichlorosilane:air:hydrogen was 1:25:4.

[0126] The present invention detects the obtained white carbon black, and the results show that the acid value of the white carbon black obtained in this example is relatively high, kept between 4.4 and 4.6, and the specific surface area is stable, and the specific surface area is 50m 2 / g~60m 2 / g, the fluctuation is small, and the average particle size is 15 μm to 16 μm.

Embodiment 3

[0128] Adopt the technical scheme of embodiment 1 to produce white carbon black, the difference is that in the present embodiment, methyltrichlorosilane: air: the mol ratio of hydrogen is 1:20:3, and the water yield of synthesis furnace section is 11m 3 / h, the water volume of the standpipe section is 9m 3 / h, the water volume of the horizontal pipe section is 7m 3 / h, the water volume of the first and second sections of the concentrator is 4m respectively 3 / h and 2m 3 / h.

[0129] The present invention detects the obtained white carbon black, and the results show that the acid value of the white carbon black obtained in this example is relatively high, kept between 4.4 and 4.6, and the specific surface area is stable, with a specific surface area of 175m 2 / g~185m 2 / g, the fluctuation is small, and the average particle size is 7 μm to 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com