A production process and device of nano fumed silica

A fumed silica and production process technology, applied in the directions of silica, silica, nanotechnology, etc., can solve the problems that the reaction process is easily affected by the outside world, the boiling point fluctuates greatly, and the activity of raw materials varies greatly, and the product model can be changed. The effect of fast adjustment, small fluctuation of specific surface area, and easy control of raw material ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

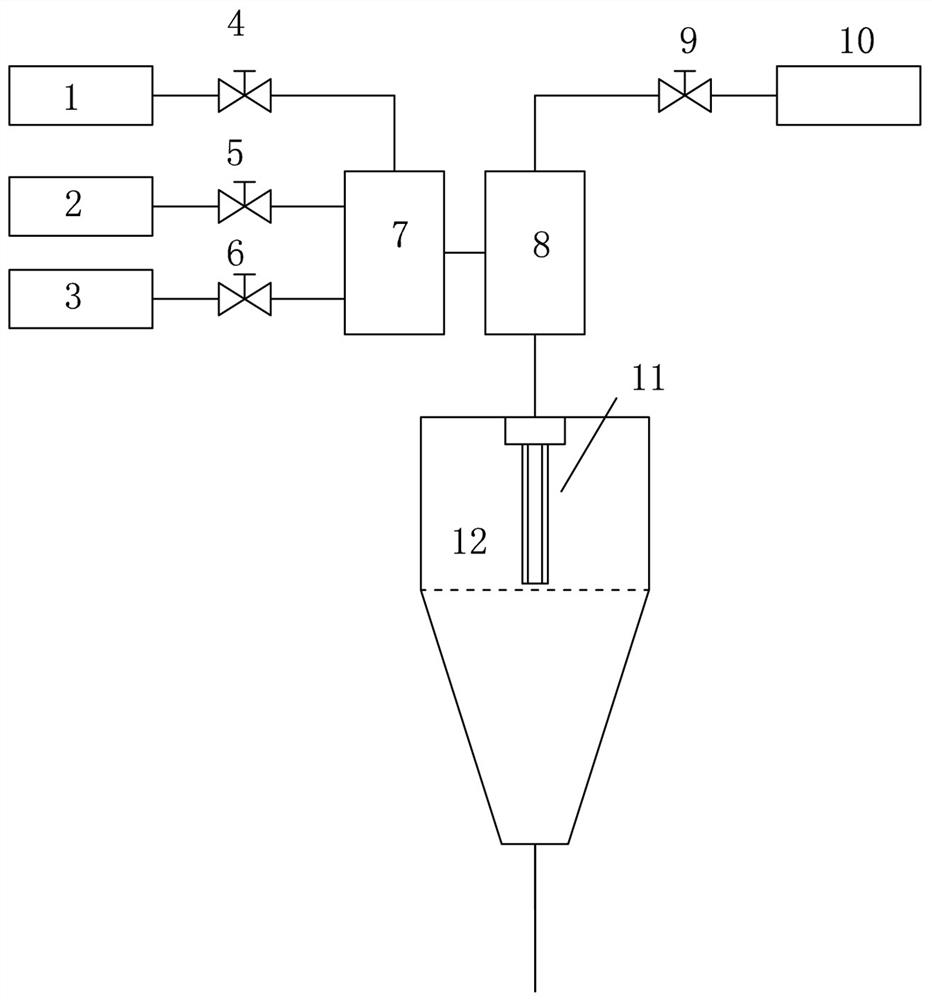

Method used

Image

Examples

Embodiment 1

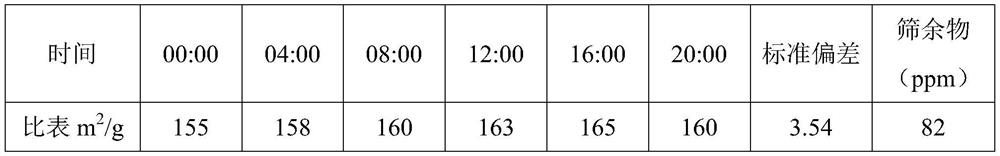

[0024] Using monomethyltrichlorosilane as raw material, the vaporization temperature is 100°C, the feeding flow rate is 280kg / h, the hydrogen flow rate is 20kg / h, and the air flow rate is 1000m 3 / h, control the raw material flow rate to 48m / h, the temperature of the mixer is 130°C, the length is 1m, the reaction temperature is 1600°C, the nominal diameter of the reactor nozzle is DN135, the pressure in the reaction furnace is -3kPa, after the reaction, the fumed silica passes through Packing after aggregation, cyclone separation and deacidification. Get the resulting product to detect, its specific surface area is 158m 2 / g, within 24 hours, sampling and testing every 4 hours, the data are as follows:

[0025]

Embodiment 2

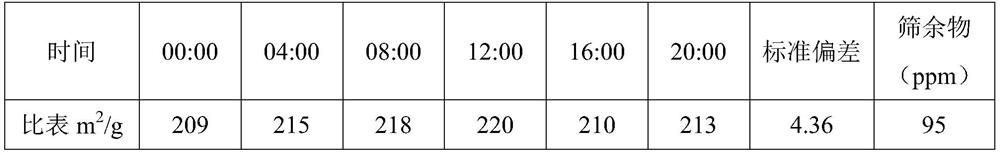

[0027] Using monomethyltrichlorosilane as raw material, the vaporization temperature is 100°C, the feeding flow rate is 250kg / h, the hydrogen flow rate is 16kg / h, and the air flow rate is 1500m 3 / h, control the raw material flow rate to 55m / h, the temperature of the mixer is 150°C, the length is 1.5m, the reaction temperature is 1400°C, the nominal diameter of the reactor nozzle is DN90, and the pressure in the reaction furnace is -5kPa. After the reaction, the fumed silica Packed after aggregation, cyclone separation and deacidification. Get the resulting product to detect, its specific surface area is 212m 2 / g, wherein within 24h, every 4h sampling detection, the obtained specific surface area and standard deviation are as follows:

[0028]

Embodiment 3

[0030] Using monomethyltrichlorosilane as raw material, the vaporization temperature is 100°C, the feeding flow rate is 200kg / h, the hydrogen flow rate is 15kg / h, and the air flow rate is 1800m 3 / h, control the raw material flow rate to 60m / h, the temperature of the mixer is 200°C, the length is 2.2m, the reaction temperature is 1400°C, the nominal diameter of the reactor nozzle is DN85, and the pressure in the reactor is -5.5kPa. Silicon is packaged after aggregation, cyclone separation, deacidification. Get the resulting product to detect, its specific surface area is 386m 2 / g, wherein within 24h, every 4h sampling detection, the obtained specific surface area and standard deviation are as follows:

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com