A kind of preparation method of regenerated antibacterial cellulose-polyvinyl alcohol composite film

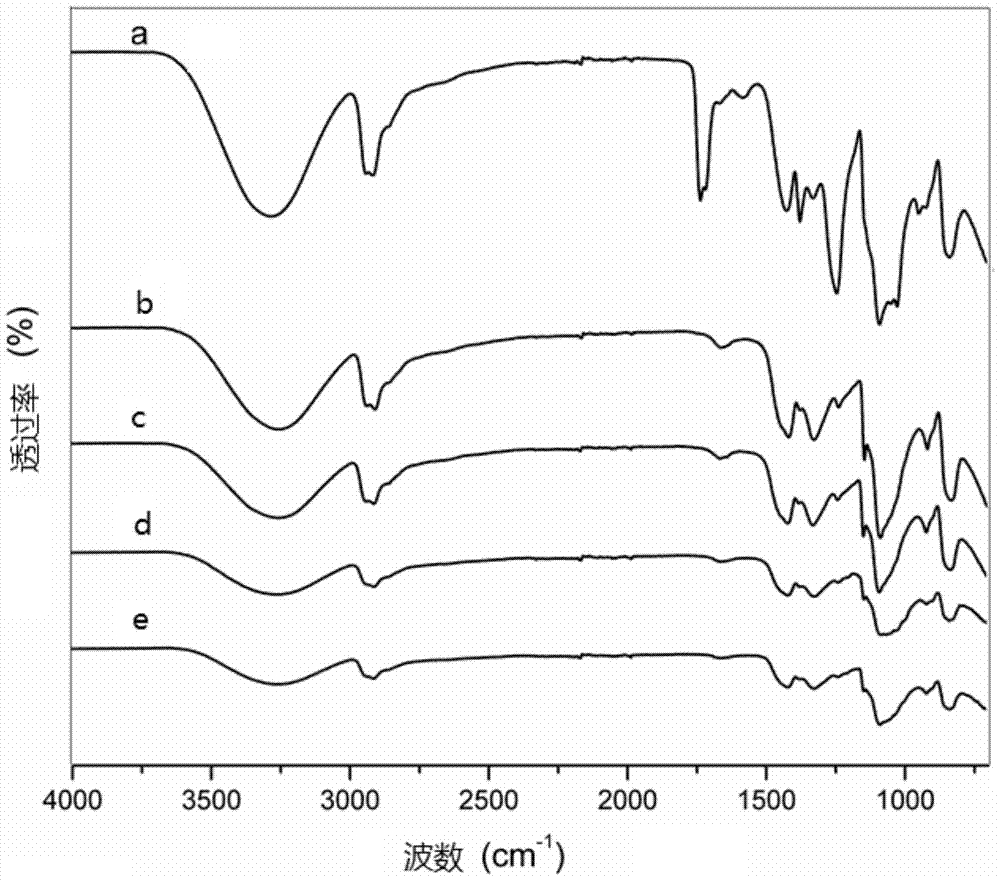

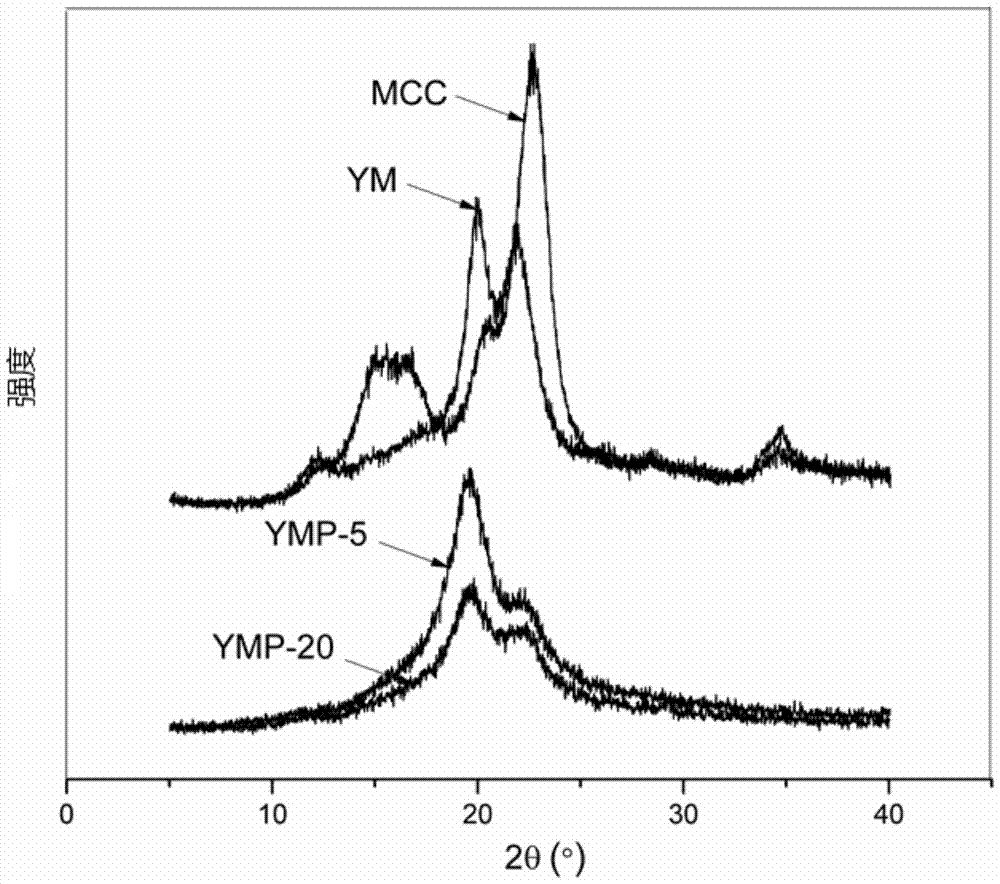

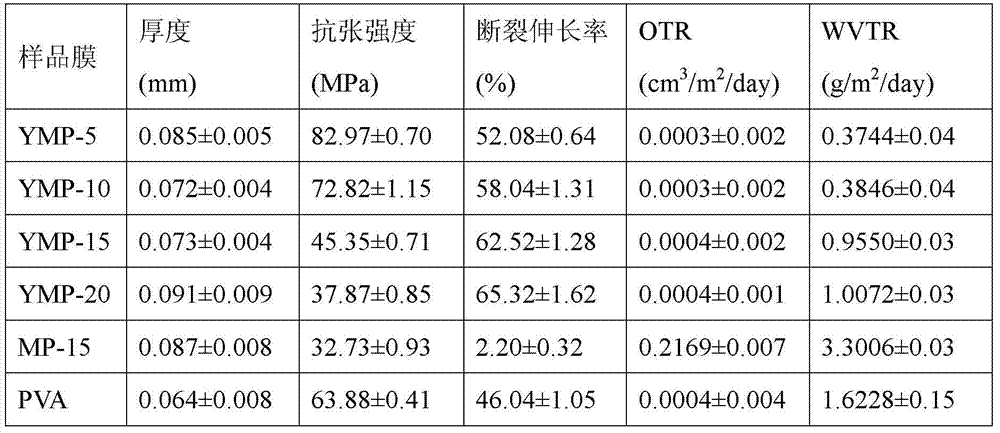

A technology of polyvinyl alcohol and cellulose, which is applied in the field of regenerated antibacterial cellulose film and its preparation, can solve the problems that cellulose is not easy to form into a film, and achieve the effects of good mechanical properties, good antibacterial properties, and good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the preparation method of a kind of regenerated antibacterial cellulose-polyvinyl alcohol composite film of the present embodiment is carried out according to the following steps:

[0019] 1. Take the reaction molar ratio of epichlorohydrin and dodecyl tertiary amine as (2.5~3.0):1, weigh epichlorohydrin and dodecyl tertiary amine and add them into the reaction vessel. Under the conditions, the reaction time is 2 to 3 hours to obtain the quaternary ammonium salt compound, and then purified by acetone recrystallization and ether cleaning to obtain the product YB;

[0020] Two, be 7~7.5% by the mass concentration of sodium hydroxide (NaOH), be 12~12.5% by the mass concentration of urea, join sodium hydroxide and urea in water, obtain mixed aqueous solution; Add 2-4% cellulose to the mixed aqueous solution to dissolve to obtain a cellulose solution;

[0021] 3. According to the mass ratio of YB and cellulose (12.67~25.33): 1, the YB obtained in ...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the molar ratio of epichlorohydrin to dodecyl tertiary amine is 2.8:1; others are the same as specific embodiment one.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reaction temperature in Step 1 is 63° C., and the reaction time is 2.5 h; the others are the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com