Beer crown cap polyolefin gasket granule

A crown cap and polyolefin technology, which is applied in the field of food packaging and polymer materials, can solve the problem that the compression deformation resistance of the gasket cannot meet the actual use requirements, the elasticity and strength of the crown cap gasket are not as good as PVC gaskets, and the adhesion is poor, etc. problems, to achieve the effect that is beneficial to human health, excellent elasticity and compression deformation resistance, toughness and strength balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with specific embodiments.

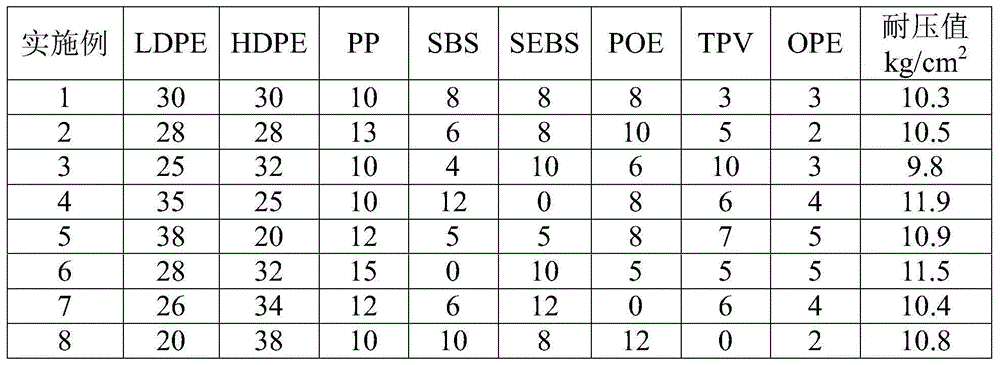

[0019] The raw materials used in the examples of the present invention are as follows: LDPE was purchased from Qilu Petrochemical 2102TN26, HDPE was purchased from Maoming Petrochemical DMDB-8920, PP was purchased from Liaoyang Petrochemical T1735, SBS was purchased from Baling Petrochemical YH-788, SEBS was purchased from Baling Petrochemical YH- 506, POE was purchased from American Dow POE8150, TPV was purchased from American Santoprene 271-55, and OPE was general food grade.

[0020] Embodiment 1~Example 8 formula composition and the pressure test value of beer bottle made therefrom.

[0021]

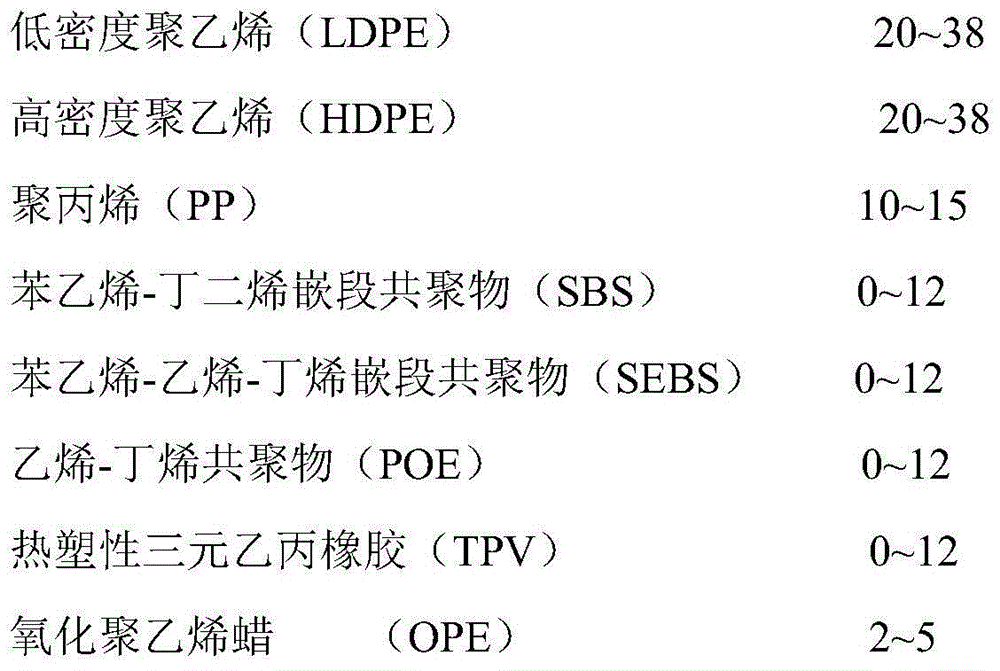

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com