Anticorrosive paint and preparation method thereof

A technology for anti-corrosion coatings and raw materials, which is applied in the field of coatings to achieve the effects of convenient construction, strong defoaming power and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

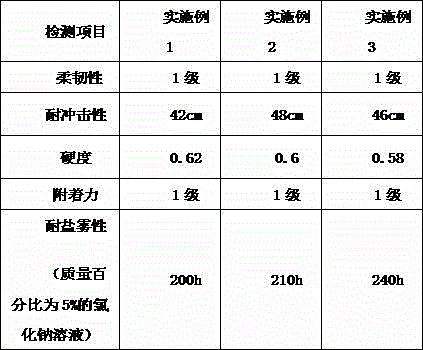

Embodiment 1

[0032] The preparation method of a kind of anticorrosion coating provided in this embodiment, comprises the following raw materials in terms of mass parts: acrylic resin: 52 parts, bisphenol A epoxy resin: 20 parts, bisphenol F epoxy resin: 5 parts, polyurethane Film former: 3 parts, modified aromatic amine epoxy curing agent: 10 parts, silicon carbide: 8 parts, defoamer: 2 parts, antirust additive: 1 part, solvent: 45 parts, pigment 5 parts, surface Active agent: 15 parts; The method is carried out as follows:

[0033] Step (1): Put bisphenol A epoxy resin and bisphenol F epoxy resin into the stirring tank for mixing, control the temperature in the stirring tank at 45°C, set the stirring speed at 520r / min, and stir for 20 minutes;

[0034] Step (2): Then put the polyurethane film-forming agent, modified arylamine epoxy curing agent, and silicon carbide into the stirring tank for mixing in sequence, set the stirring speed to 620r / min, and the stirring time to 42min;

[0035] ...

Embodiment 2

[0038] The preparation method of a kind of anticorrosion coating provided in this embodiment comprises the following raw materials in terms of mass parts: acrylic resin: 53 parts, bisphenol A epoxy resin: 22 parts, bisphenol F epoxy resin: 7 parts, polyurethane Film forming agent: 4 parts, modified aromatic amine epoxy curing agent: 12 parts, silicon carbide: 9 parts, defoamer: 3 parts, antirust additive: 2 parts, solvent: 48 parts, pigment 10 parts, surface Active agent: 17 parts; The method is carried out as follows:

[0039] Step (1): Put bisphenol A epoxy resin and bisphenol F epoxy resin into the stirring tank for mixing, control the temperature in the stirring tank at 46°C, set the stirring speed at 525r / min, and stir for 22 minutes;

[0040] Step (2): Then put the polyurethane film-forming agent, modified arylamine epoxy curing agent, and silicon carbide into the stirring tank for mixing in sequence, set the stirring speed to 640r / min, and the stirring time to 44min;

...

Embodiment 3

[0044] The preparation method of a kind of anti-corrosion coating provided in this embodiment comprises the following raw materials in terms of parts by mass: acrylic resin: 55 parts, bisphenol A epoxy resin: 23 parts, bisphenol F epoxy resin: 8 parts, polyurethane Film forming agent: 5 parts, modified aromatic amine epoxy curing agent: 15 parts, silicon carbide: 12 parts, defoamer: 4 parts, antirust additive: 3 parts, pigment 15 parts, solvent: 50 parts, surface Active agent: 18 parts; The method is carried out as follows:

[0045] Step (1): Put bisphenol A epoxy resin and bisphenol F epoxy resin into the stirring tank for mixing, control the temperature in the stirring tank at 48°C, set the stirring speed at 530r / min, and stir for 25 minutes;

[0046] Step (2): Then put the polyurethane film-forming agent, modified arylamine epoxy curing agent, and silicon carbide into the stirring tank for mixing in sequence, set the stirring speed to 650r / min, and the stirring time to 45mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap