A valve seat ring for an alternative fuel engine

A valve seat ring and alternative fuel technology, used in engine components, turbines, mechanical equipment, etc., can solve the problems of fuel corrosion and wear, engine jitter, poor lubrication conditions, etc., to increase self-lubrication, improve wear resistance, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The valve seat ring of an alternative fuel engine, its chemical composition (weight percentage) is: C content 1%, Si content 0.9%, Mn content 0.5%, S content 0.7%, Ni content 6%, Cr content 5%, Mo content 12 %, Co content 23%, balance Fe.

[0025] The valve seat ring adopts the processing method of powder metallurgy in a vacuum environment, and adopts two pressing and two sintering manufacturing processes in the processing process.

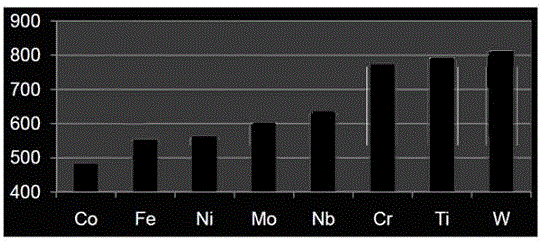

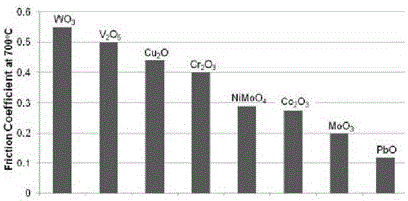

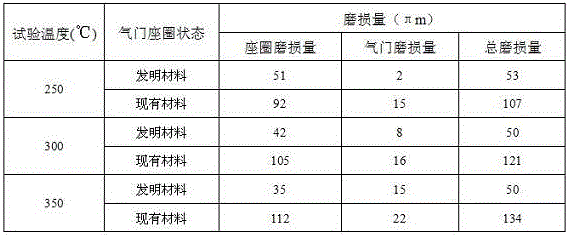

[0026] In the present invention, in order to improve the wear resistance and self-lubricating property of the valve seat ring material, the type of hard particles is improved and the content of hard particles is increased. The hard particle material is changed from the existing Cr-W-C system to have high Co-Mo-Cr series materials with high strength and lubricating properties. Compared with Cr-W-C series, Co-Mo-Cr series hard particles have a smaller dynamic friction coefficient and better self-lubricating properties, such as figure 1 The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com