Vanadium oxide-loaded boron fuel with high energy density and impregnation preparation method thereof

A vanadium oxide, impregnation technology, applied in nuclear power generation, offensive equipment, explosives processing equipment, etc., can solve the problems of boron fuel ignition and combustion performance improvement, achieve low initial oxidation temperature, shorten laser ignition delay time, The effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

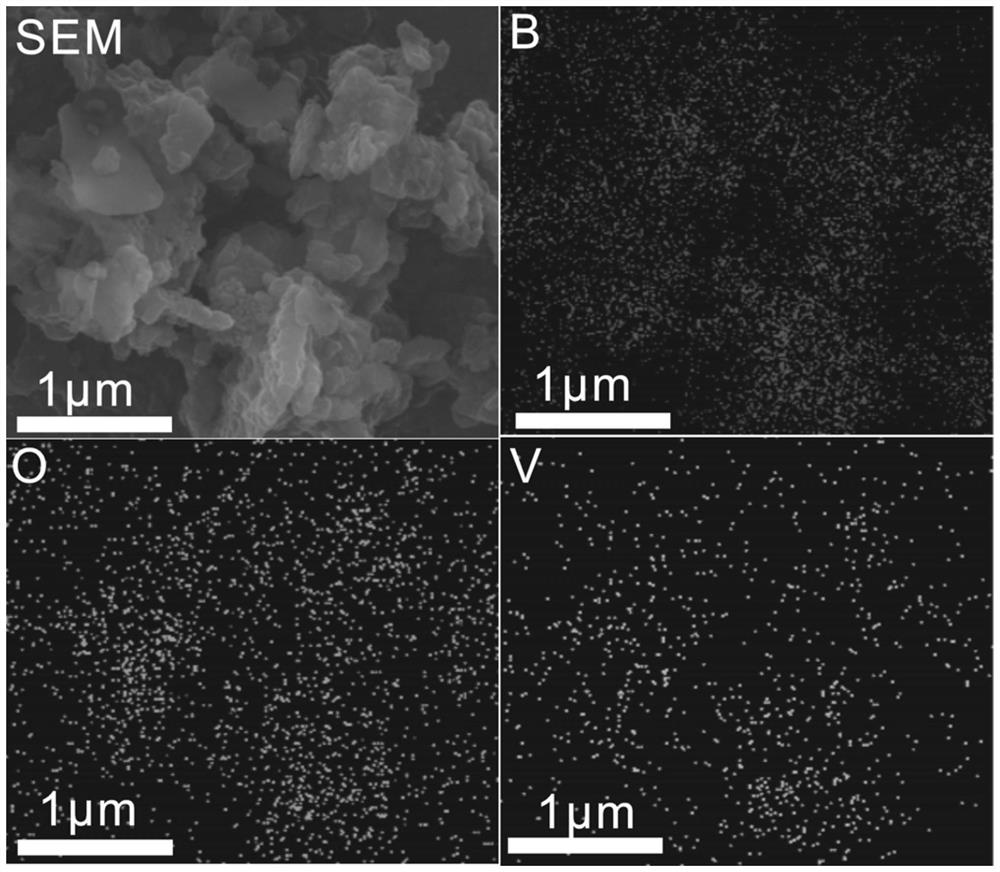

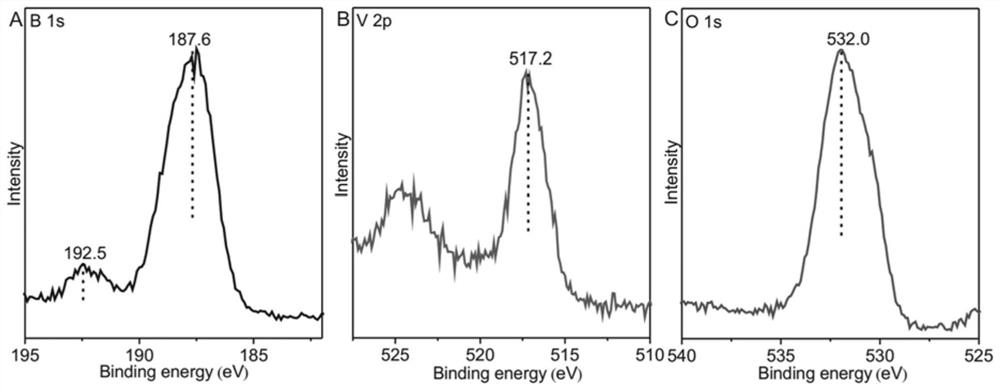

[0041] The present embodiment provides a method for preparing a vanadium oxide-loaded boron fuel by an impregnation method. The method adopts an impregnation method to load vanadium oxide on the surface of boron powder to form a vanadium oxide-loaded boron fuel;

[0042] The impregnation method is based on NH 4 VO 3 The aqueous solution is an impregnation solution, and the boron powder particles are completely infiltrated, dried and calcined to obtain a vanadium oxide-loaded boron fuel;

[0043] Vanadium oxide is V 2 O 2, V 2 O 3 , VO 2 , V 2 O 4 and V 2 O 5 one or more of.

[0044] The equation for the reaction of the impregnation method is:

[0045]

[0046] Specifically, the method specifically includes the following steps:

[0047] Step 1, adding boron powder in the reaction vessel, then testing its saturated water absorption with water to obtain the volume of the dipping solution required by the boron powder;

[0048] Step 2, weigh 1g of boron powder and p...

Embodiment 2

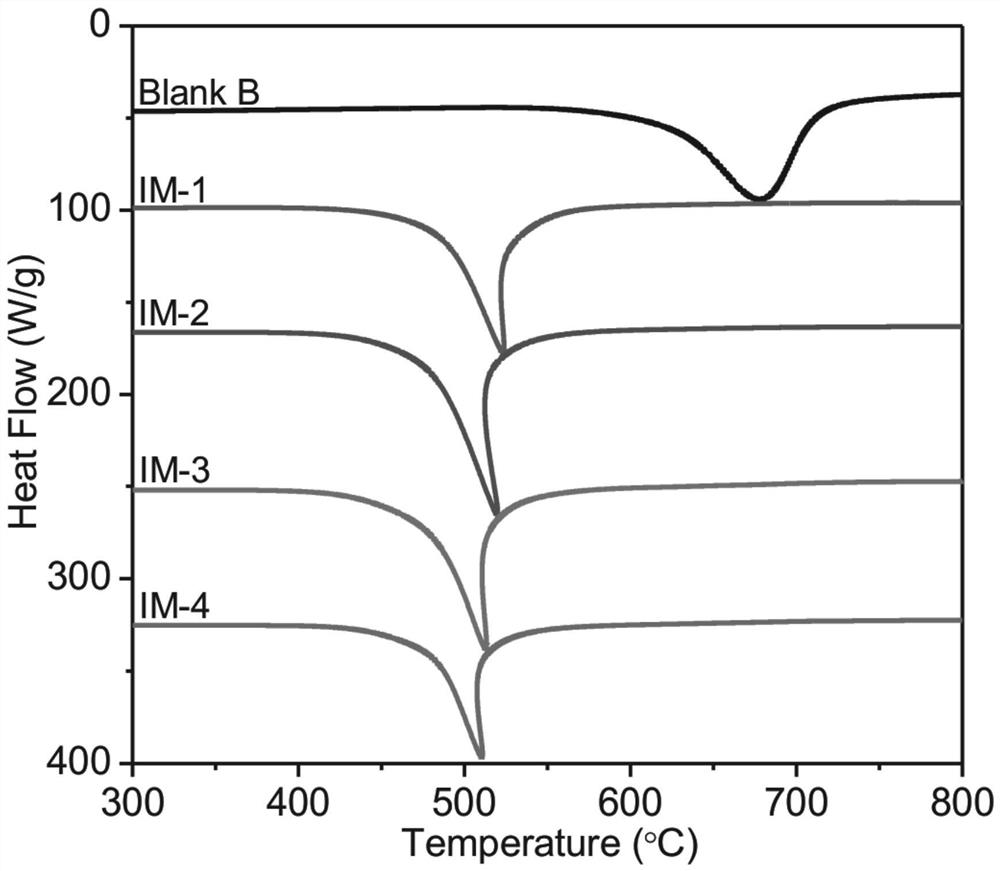

[0056] This example provides the TG-DSC test of the vanadium oxide-loaded boron fuel. The TG-DSC test method is: weigh an appropriate amount of vanadium oxide-loaded boron fuel and place it in the sample stage of the TG-DSC instrument, set the instrument The heating rate is 10 °C / min, the test temperature range is 50-1000 °C, and the test atmosphere is air atmosphere, so that the TG and DSC curves of the vanadium oxide-loaded boron fuel can be obtained.

[0057] Specifically, weigh an appropriate amount of vanadium oxide-loaded boron fuel and place it in the sample stage of the TG-DSC instrument, set the heating rate of the instrument to be 10°C / min, the test temperature range to be 50-1000°C, and the test atmosphere to be an air atmosphere , so the TG and DSC curves of the vanadium oxide-loaded boron fuel can be obtained.

[0058] Table 1 shows the TG-DSC data of the vanadium oxide supported boron fuel of the present invention.

[0059] Table 1 Combustion performance of boro...

Embodiment 3

[0064] This example provides the ignition delay time test of the vanadium oxide-loaded boron fuel. The method for the ignition delay time test is: weigh an appropriate amount of vanadium oxide-loaded boron fuel and place it in the sample stage of the laser ignition instrument, and set the instrument parameters. is frequency Hz: 1000; duty cycle (1-40%): 3; pulse number: 1000; pulse train output light; power: 40W; pulse energy: 40mJ; pulse width: 30μs. In this way, the ignition delay time data of the vanadium oxide-loaded boron fuel can be obtained.

[0065] Specifically, weigh an appropriate amount of vanadium oxide-loaded boron fuel into the sample stage of the laser ignition instrument, and set the instrument parameters as frequency Hz: 1000; duty cycle (1-40%): 3; pulse number: 1000; pulse String light; power: 40W; pulse energy: 40mJ; pulse width: 30μs. like image 3 As shown, the ignition delay time of the vanadium oxide-loaded boron fuel prepared by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com