Automatic thickened oil detection system and automatic oil extraction assistant injection amount adjusting system

An automatic detection and automatic adjustment technology, applied in the fields of measurement, production of fluids, and earth-moving drilling, etc., can solve problems such as harmful gas leakage, personnel poisoning, and decline in production capacity of oil wells, so as to avoid pollution and waste, ensure stable production, and eliminate Effects of Environmental Errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

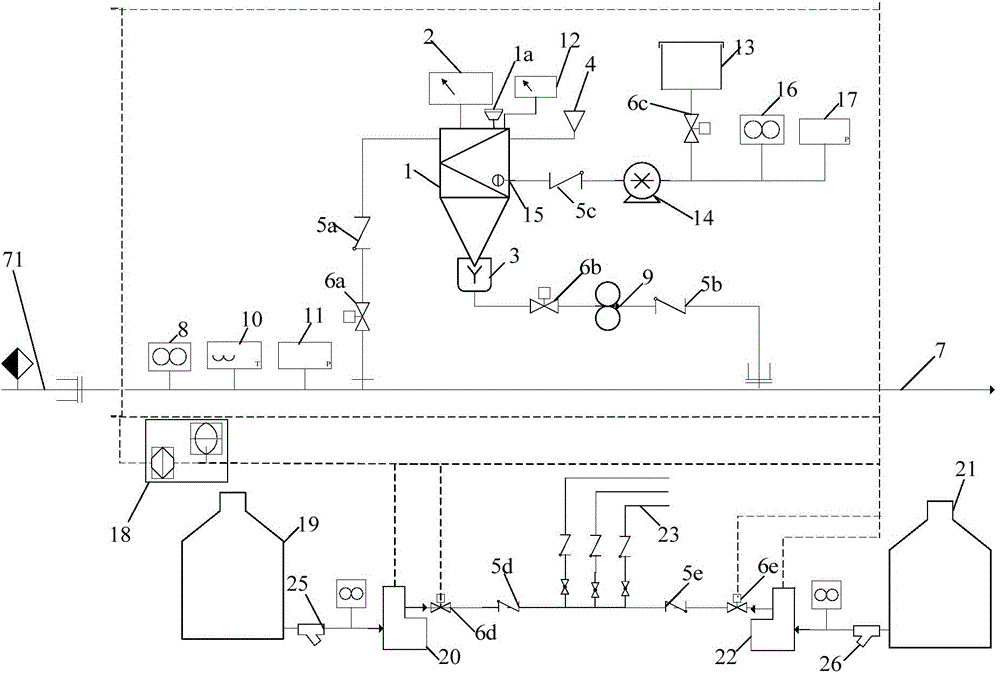

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

[0042] Such as figure 1 As shown, the heavy oil automatic detection system according to the embodiment of the present invention includes a detection container 1, a crude oil moisture analyzer 2, a stirring device 3 and a liquid level sensor 4, wherein: the top of the detection container 1 is provided with an exhaust device 1a, the oil inlet of the detection container 1 is connected to the crude oil main pipeline 7 through the first check valve 5a and the first electric valve 6a, and the connection point and the access point 71 of the crude oil main pipeline 7 are provided with A flowmeter 8, the stirring device 3 is installed on the bottom of the detection container 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com