Proportional hydraulic control valve group and metal belt continuously variable transmission

A technology of continuously variable transmission and hydraulic control valve, which is applied in transmission control, components with teeth, belts/chains/gears, etc. It can solve the problem of poor filtration accuracy control, pressure stability, large valve plate size requirements, and high precision requirements. Problems, to achieve the effect of strong anti-pollution ability, less assembly size requirements, and low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

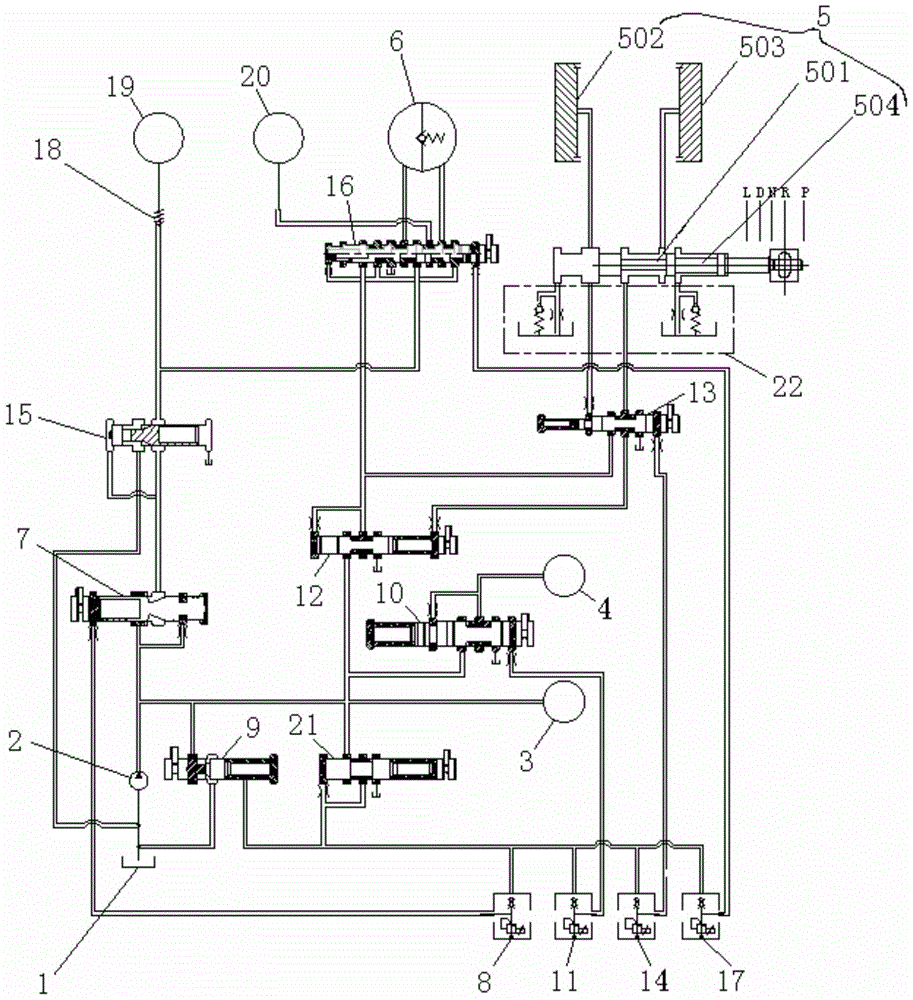

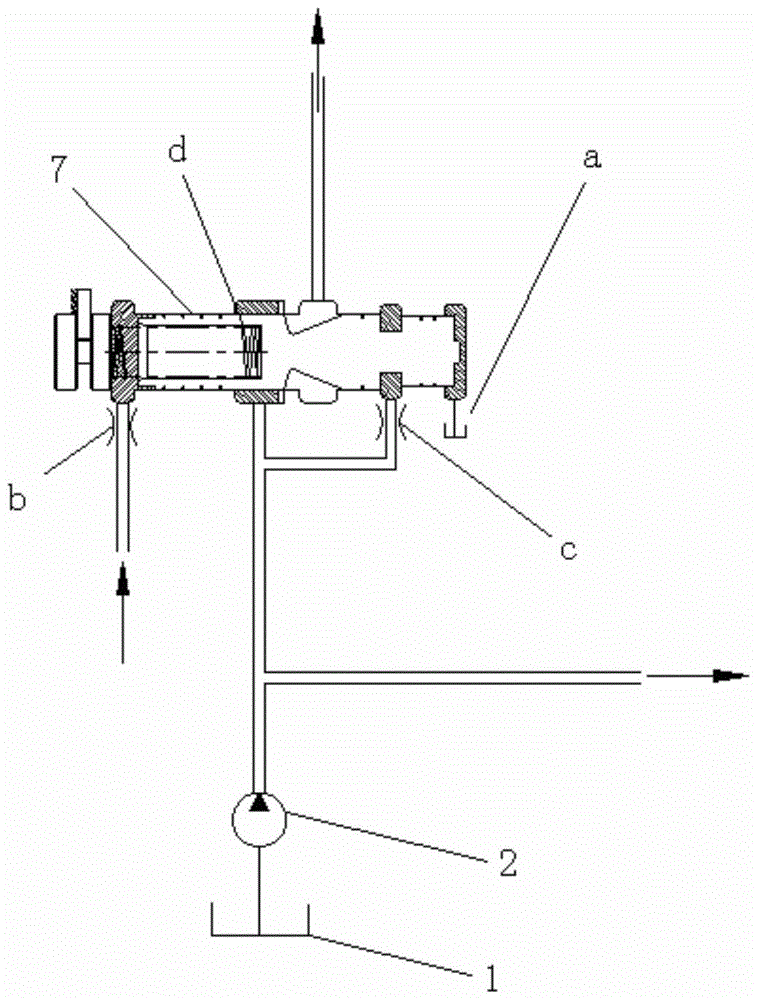

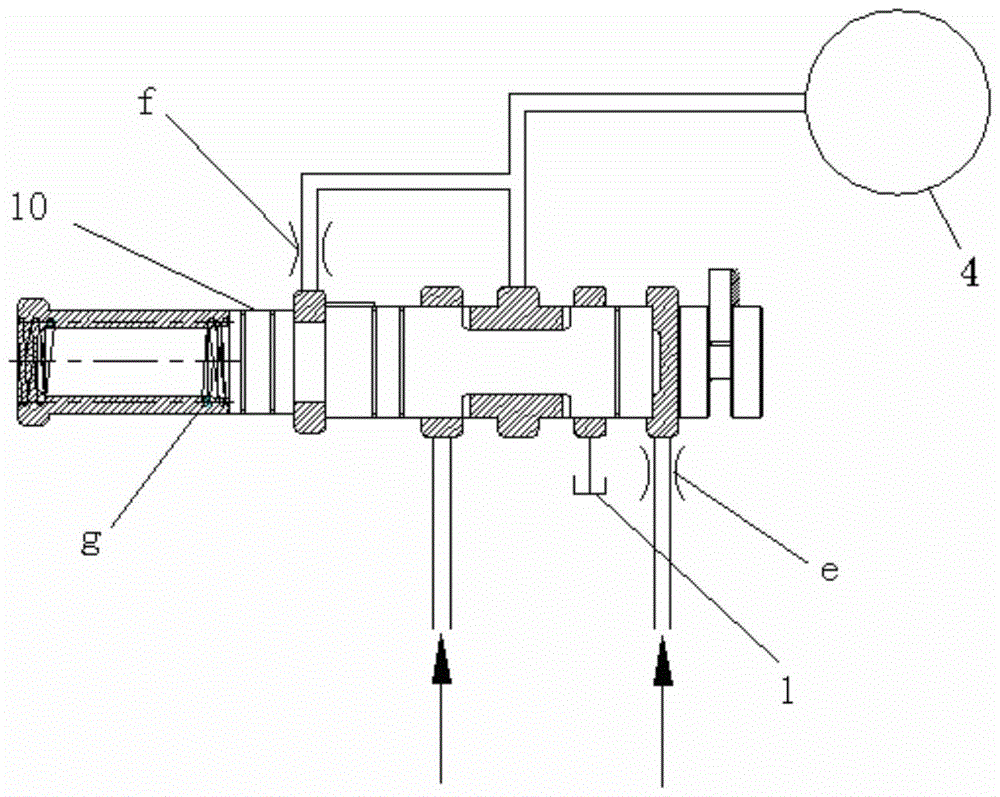

[0028] figure 1 It is a structural schematic diagram of a proportional hydraulic control valve group for a metal belt continuously variable transmission according to a preferred embodiment of the present invention; figure 2 It is a structural schematic diagram of a passive slide valve in a preferred embodiment of the present invention; image 3 It is a structural schematic diagram of an active slide valve in a preferred embodiment of the present invention; Figure 4 It is a structural schematic diagram of the clutch hydraulic part of the preferred embodiment of the present invention; Figure 5 It is a structural schematic diagram of the backstop impact buffer device in the preferred embodiment of the present invention.

[0029] Such as figure 1 with figure 2As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com