Real-time online cavitation monitoring and warning system and real-time online cavitation monitoring and warning method for water pump of thermal power station

A monitoring and early warning technology for thermal power plants, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

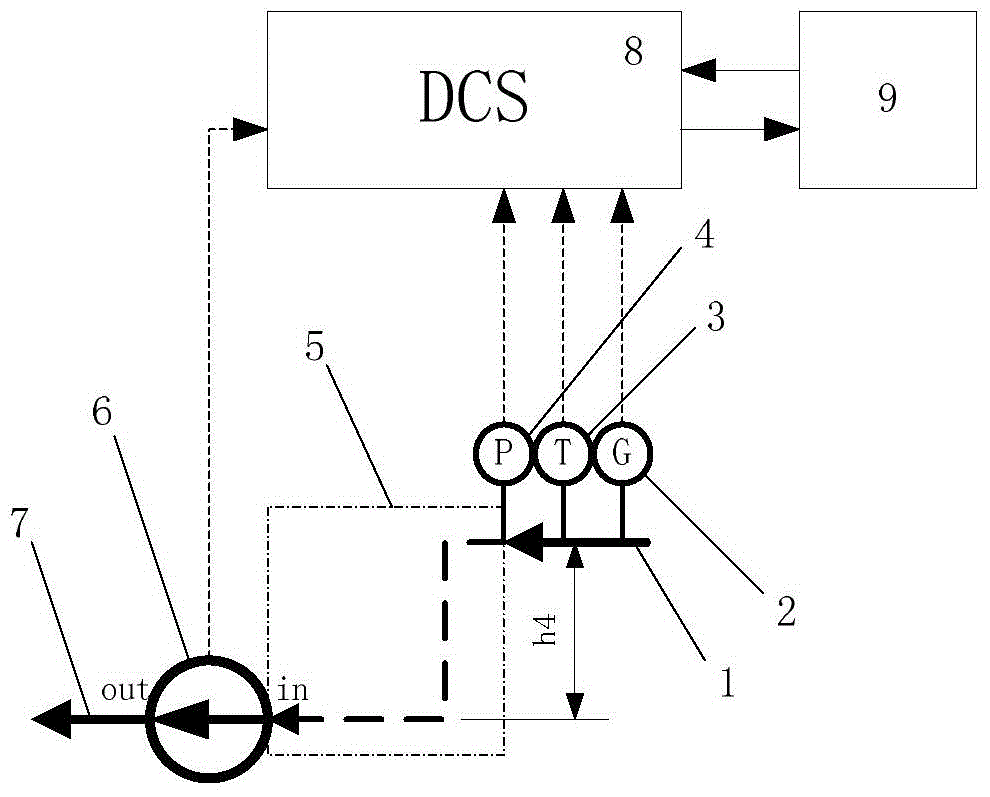

[0057] As shown in the accompanying drawings, the present invention provides a real-time online cavitation monitoring and early warning system for water pumps in thermal power stations, including an external monitoring unit 9 connected to the DCS control system 8 of the power station, a monitoring target water pump 6, a pipeline flow sensor 2, and a pump upstream temperature sensor 3 and the pump upstream pressure sensor 4; the pump upstream temperature sensor 3 and the pump upstream pressure sensor 4 are the pressure and temperature measurement sensors that monitor the target water pump 6 on the pipeline where the monitoring target water pump 6 is the nearest; the monitoring target water pump 6 and the upstream pressure sensor The pipes and pipeline elements between 4 constitute the upstream pipe section 5; the external monitoring uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com