Two-stage airflow powder material drying device

A powdery material and drying device technology, which is applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of easy agglomeration and incomplete drying of powdery materials, so as to avoid agglomeration, increase drying time, The effect of increasing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

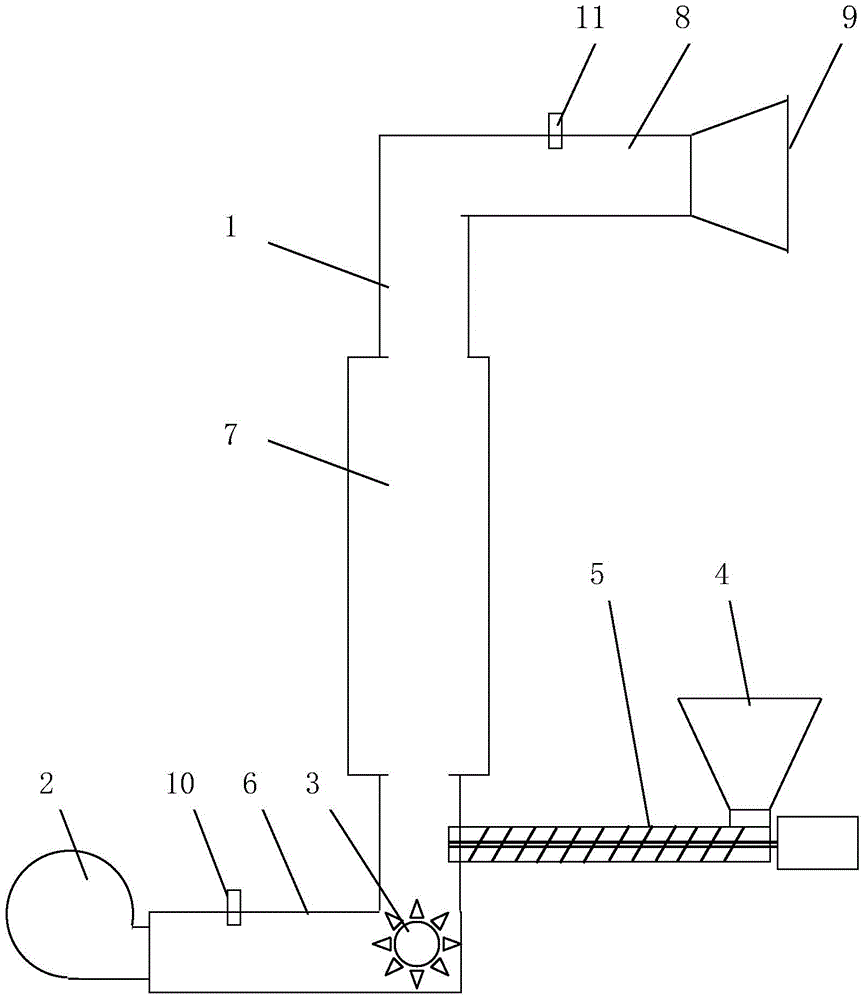

[0015] like figure 1 As shown, the two-stage airflow powdery material drying device includes a vertical drying pipe 1, an induced draft fan 2, a pulverizer 3, a mixer 4 and a screw feeder 5, and the induced draft fan 2 is connected to the vertical The bottom end of the drying pipe 1 is provided with a pulverizer 3 in the pipe at the joint, and the mixer 4 is arranged on the side of the vertical drying pipe 1 through a screw feeder 5, and the center of the vertical drying pipe 1 is an expansion part 7 , the top of the vertical drying pipe 1 is connected to the discharge port 9 through the discharge pipe 8 .

[0016] The diameter of the vertical drying pipe 1 is 420 mm, and the diameter of the expansion part 7 is 630 mm.

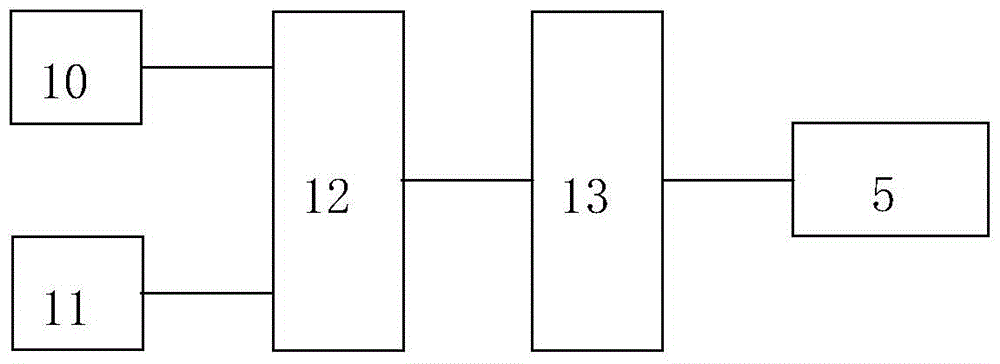

[0017] like figure 2 As shown, the air inlet pipe 6 is provided with an air inlet temperature sensor 10, and the outlet pipe 8 is provided with an outlet temperature sensor 11, and the inlet air temperature sensor 10 and the outlet temperature sensor 11 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com