A cold emitter sealing cover

A transmitter and sealing cover technology, which is applied in the field of sealing structure of cold transmitters, can solve problems such as the inability to ensure accurate locking of the internal signal of the transmitter, lack of wave-transmitting performance, and poor thermal insulation performance, and achieve simple and reliable structure, low weight, etc. Lightweight, fast-response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

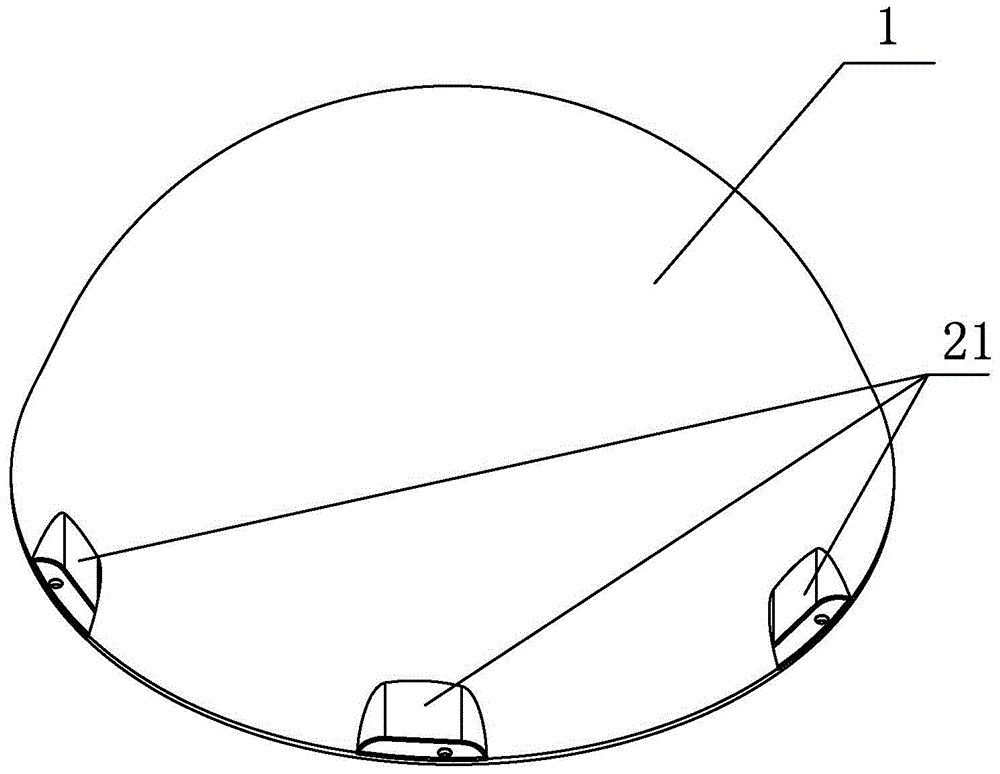

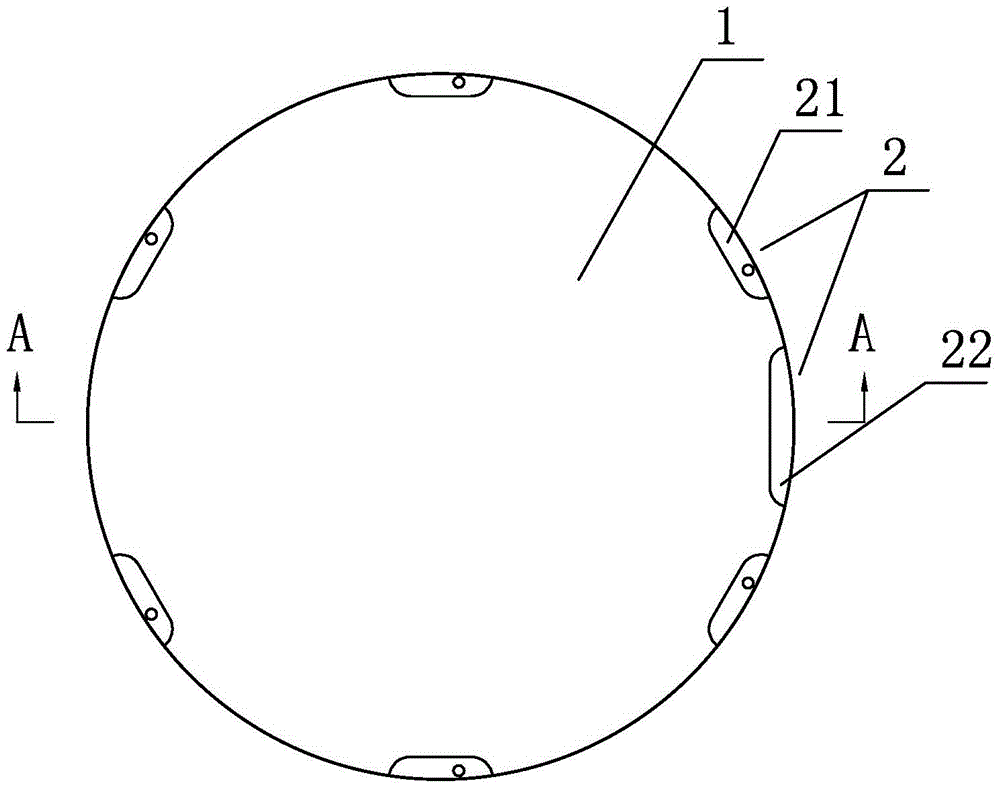

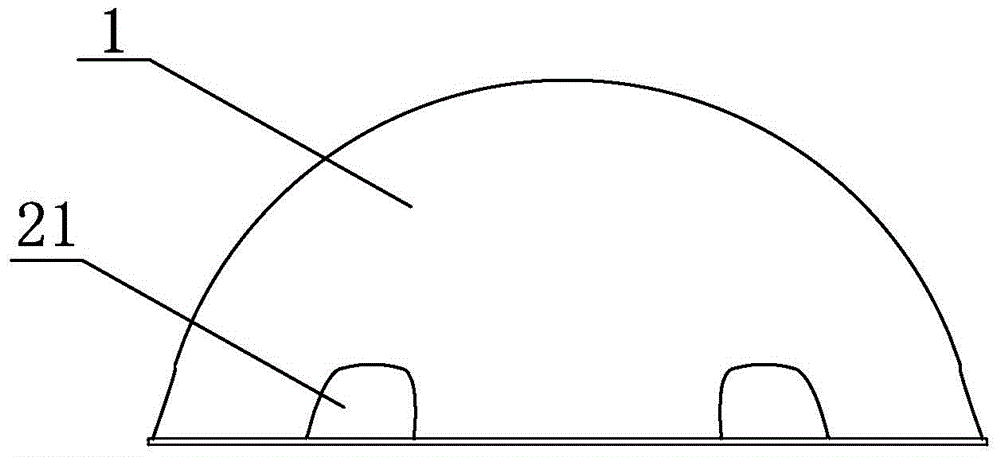

[0027] Such as Figure 1-5 As shown, the cold emitter seal cover of the present embodiment is installed on the flange of the launch tube mouth of the cold emitter, the seal cover is a spherical crown cover 1, and the outer surface of the spherical crown cover 1 opening is provided with at least two There are four sinking platforms 2, preferably 7, of which 6 sinking platforms 2 are connection interfaces 21, and the connection interfaces 21 are evenly arranged on the outer circumferential surface of the bottom of the spherical crown cylinder cover 1. The bottom of the sink platform of the connection interface 21 is a flange connecting plate 211, on which there is a connection hole 212, which is used to screw the spherical crown tube cover 1 on the flange of the launch tube, and the remaining sink platform 2 is a hinged interface 22 , the hinge interface 22 is located at the lowermost end of the spherical crown cover 1, and the hinge interface 22 is set between any two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com