Dot matrix structure body test machine and shipping plan linked intelligent division test method

A technology of dot matrix structure and shipping plan, applied in the direction of calculation, measuring device, manufacturing computing system, etc., can solve the problems of patterned fireworks that cannot be miniaturized, lack of technical support, and restrict the overall cost of patterned fireworks, and achieve cost reduction. Low, optimized production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

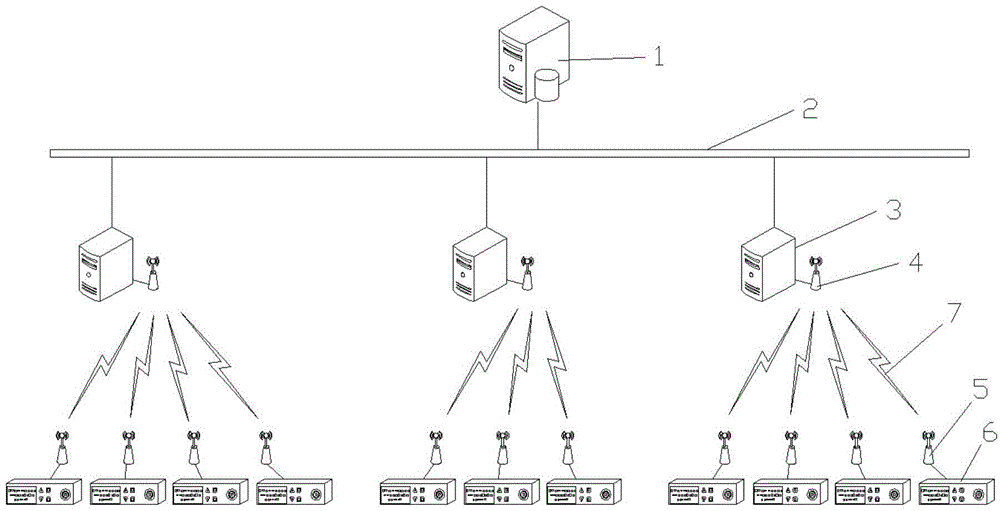

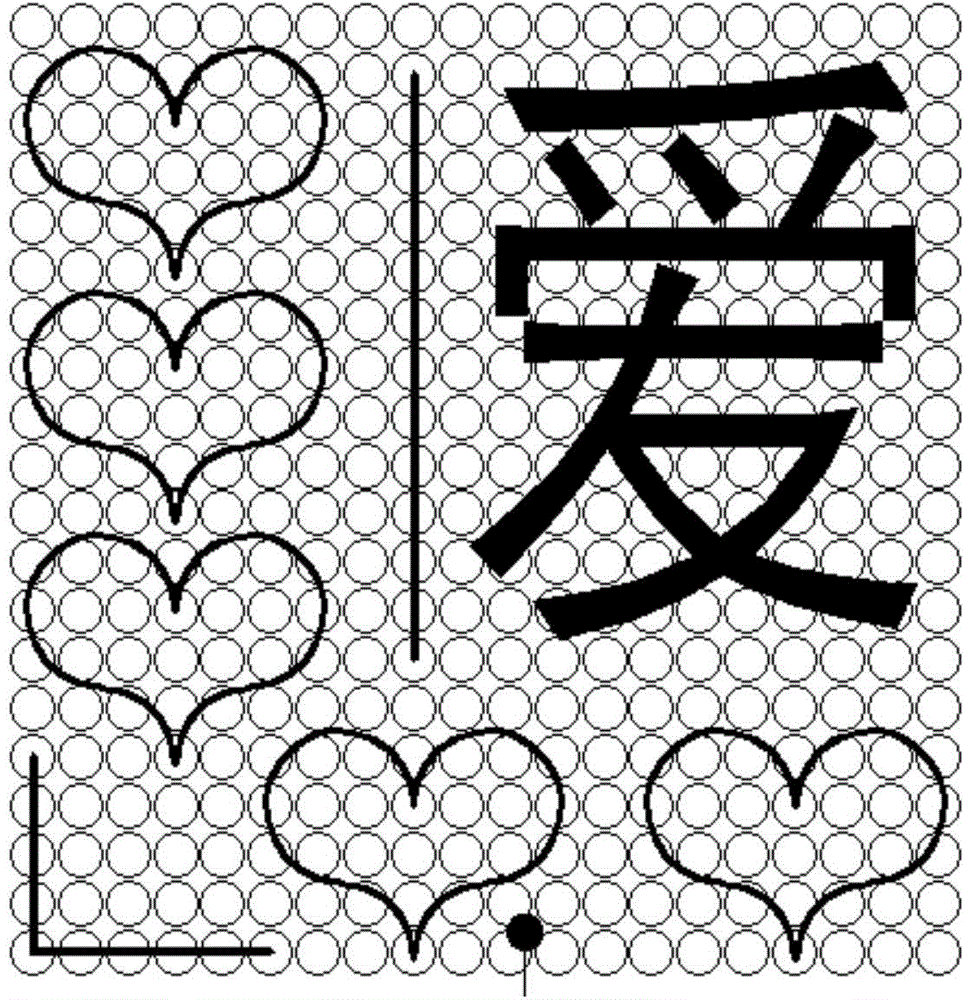

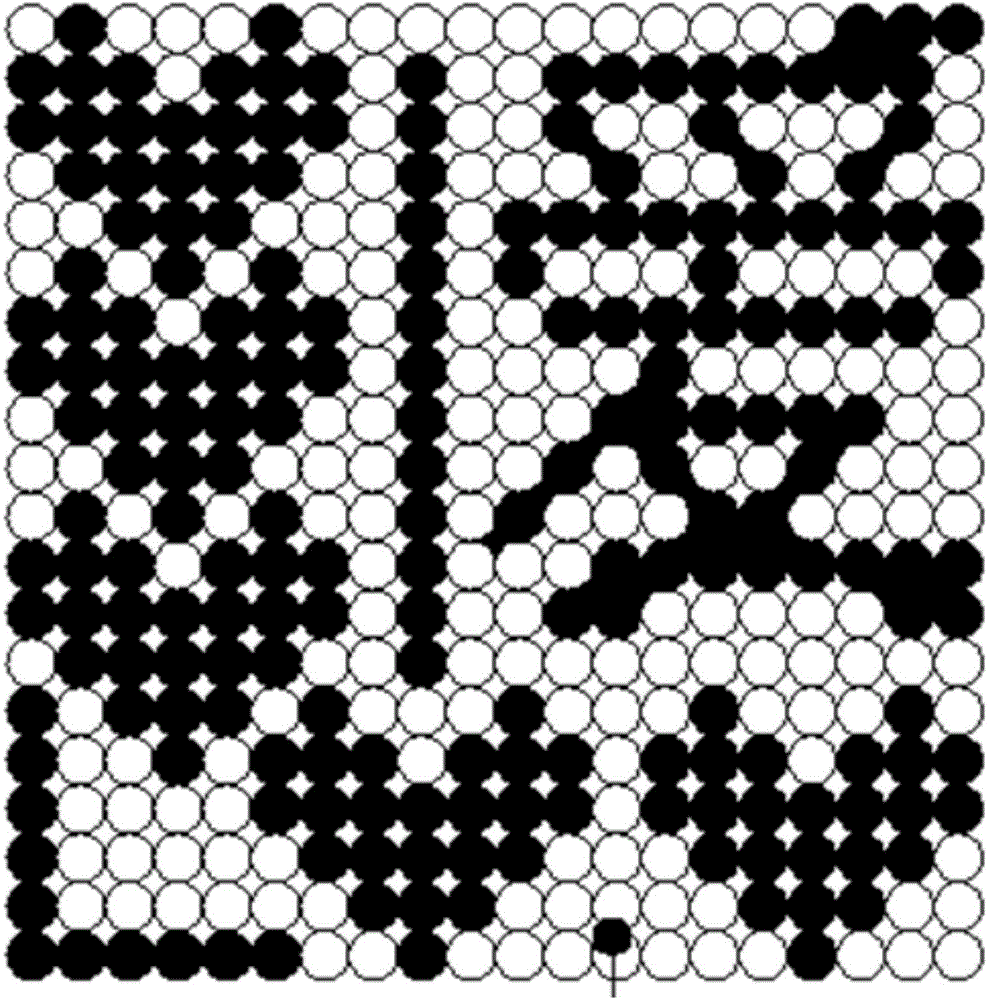

[0035] refer to Figure 1-Figure 3 As shown, the intelligent segmentation test method for the linkage between the lattice structure testing machine and the shipping plan, including the lattice structure intelligent test networking method, the lattice structure testing machine grouping and testing linkage method, and the shipping plan and real-time production completion In the dynamic distribution method, the lattice structure intelligent test networking method can connect countless lattice structure test machines to the host computer of the shipment plan through a wireless or wired network, and the lattice structure test machines are grouped and tested The linkage method can arrange the production task instruction to the specific lattice structure testing machine, and the dynamic allocation method of the shipment plan and the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com