Graphite electrode horizontal moving device

A technology of graphite electrodes and movers, applied in the field of devices for horizontally moving graphite electrodes, can solve the problems of a large left and right swing range of the adjusting gear, the inability of the adjusting gear to press the graphite electrode tightly, and the unsmooth movement of the adjusting gear up and down. Simple structure, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

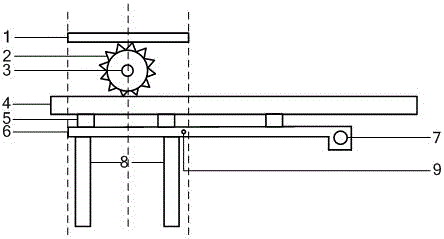

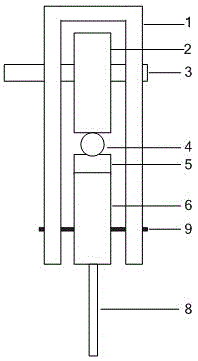

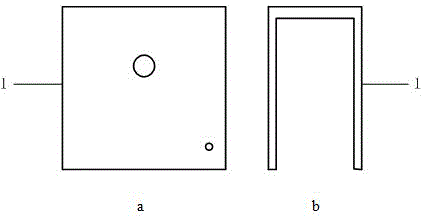

[0014] Such as figure 1 As shown, a graphite electrode horizontal mover includes a horseshoe-shaped metal frame 1, an adjusting gear 2, a gear linkage rod 3, a small U-shaped electrode fulcrum 5, a wire connecting beam 6, a wire connecting hole 7, a double-leg support 8 and a steel wire plug Bolt 9.

[0015] The horseshoe-shaped metal frame 1 is cut from a whole block of metal, and the thickness is 3 millimeters. The adjusting gear 2 passes through the horseshoe-shaped metal frame 1 and is installed in the middle of the horseshoe-shaped metal frame 1 through the gear linkage rod 3 . Three small U-shaped electrode fulcrums 5 are installed on the wire connection beam 6 from left to right, the leftmost small U-shaped electrode fulcrum 5 is installed on the leftmost position of the wire connection beam 6, and the middle small U-shaped electrode fulcrum 5 It is installed in a position symmetrical to the small U-shaped electrode fulcrum 5 on the left with the adjustment gear 2 as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com