Thrust/torque measuring device for pod test

A torque measurement and thrust technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems that the size of the device cannot meet the standard required by the test, consume a lot of manpower and material resources, research misleading effects, etc., and achieve prediction and optimized performance, convenient and concise layout, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

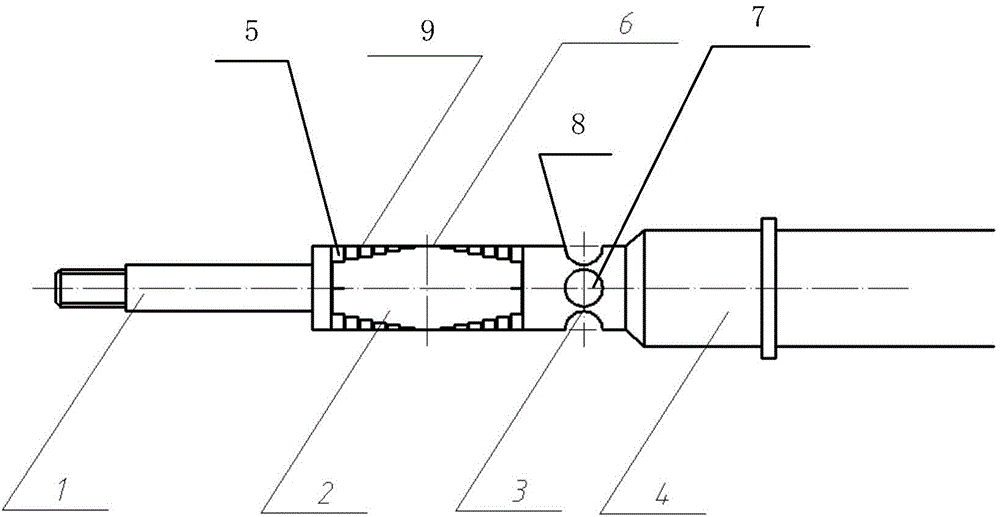

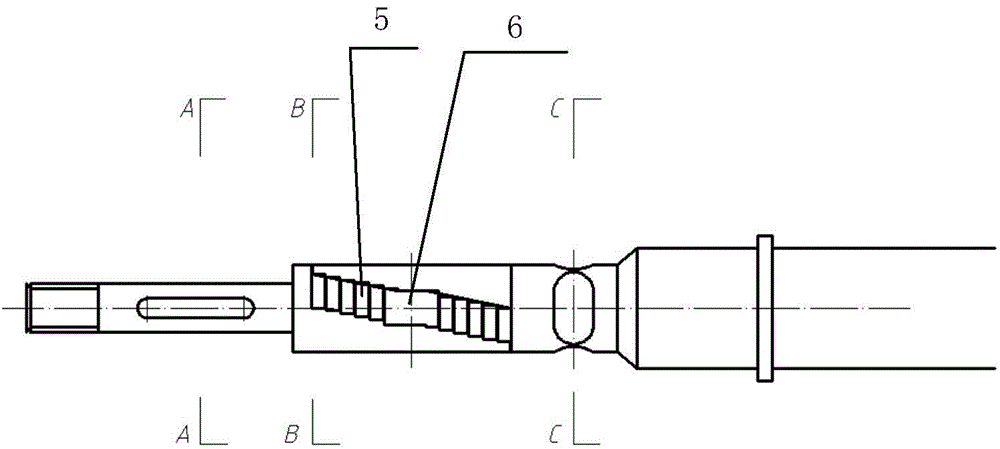

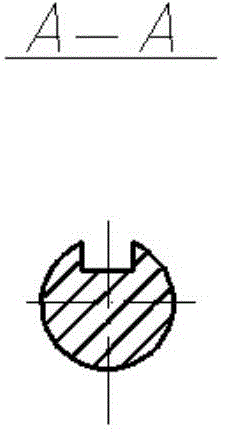

[0010] to combine Figure 1 to Figure 3(C) , the present invention includes a built-in motor in the cabin, a main shaft 4 connected to the output shaft of the built-in motor in the cabin, a thrust torque sensor connected to the main shaft 4, a propeller installation shaft 1 connected with the thrust torque sensor, and a set on the propeller installation shaft 1 The propeller, the thrust torque sensor includes a torque measurement section 3 and a thrust measurement section 2, the center of the torque measurement section 3 is provided with an opening 7, and the first full-bridge strain gauge is pasted in the opening 7, and in the opening 7 Semicircular grooves 8 are symmetrically arranged on both sides, and the middle position of the thrust measuring section 2 is pasted with a second full-bridge strain gauge 6, and a row of through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com