Strength testing device

A technology of strength testing and cylinder body, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effects of simple structure, avoiding damage to electric devices, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

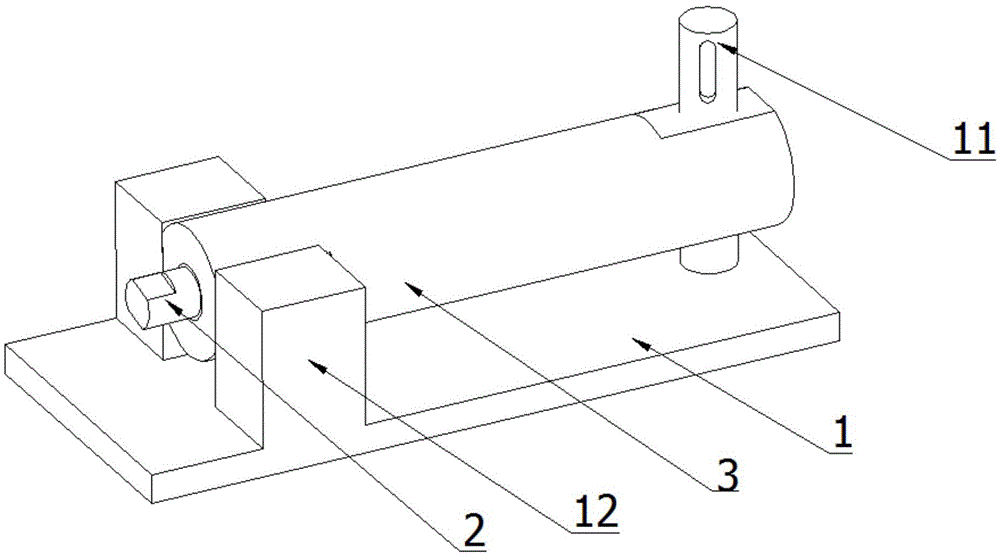

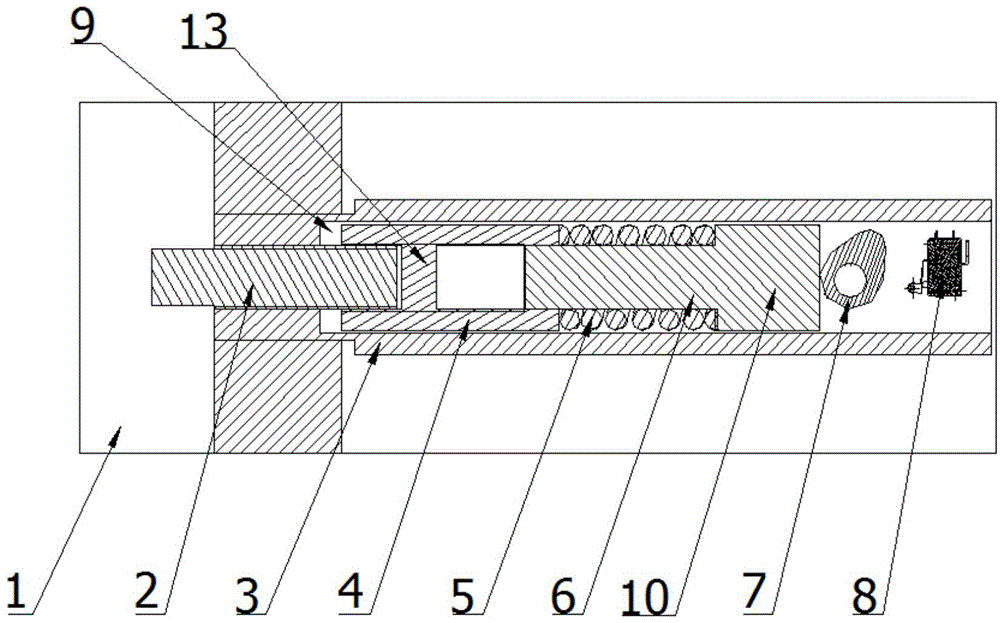

[0020] Such as figure 1 , 2 As shown, this embodiment discloses a strength testing device, which includes a base 1 and a cylinder 3 installed on the base;

[0021] There is a cavity 9 inside the cylinder, in which an adjusting lead screw 2, a compression sleeve 4, a thrust rod 6, and a cam 7 are sequentially installed along the axis of the cylinder. internal thread, the adjusting screw rod passes through the opening and extends into the cavity, and the adjusting screw rod is threadedly connected with the opening;

[0022] The compression sleeve is sleeved on one end of the thrust rod, and the inner cavity of the compression sleeve is tubular or cylindrical, and a blocking part is arranged in the cavity, and the extending end of the adjusting screw rod abuts against the blocking part; Driven, the compression sleeve can move horizontally on the thrust rod;

[0023] The other end of the thrust rod is provided with a limiting boss 10, which is integrally formed with the thrust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com