Capsule detection method and high-speed fully-automatic detection device

A detection method and fully automatic technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of high cost, low detection efficiency, soft capsule pollution, etc., and achieve the effect of reliable and durable performance, high detection accuracy, and smooth feeding and discharging.

Inactive Publication Date: 2015-05-20

HANGZHOU QOGORI TECH

View PDF8 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The working status of the inspector has a great influence on the detection effect, and this working method has low detection efficiency, high cost and high labor intensity

It is easy to miss inspection, the detection rate of defective products is low, the quality is unstable, and the soft capsules are directly touched by hands, which inevitably leads to pollution of the soft capsules

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

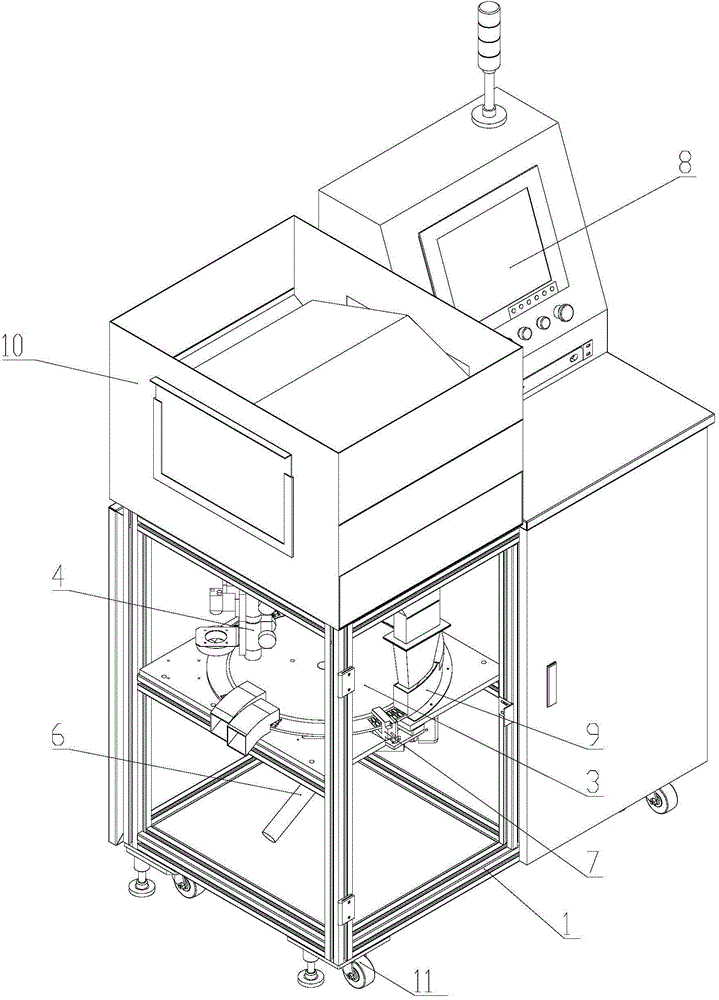

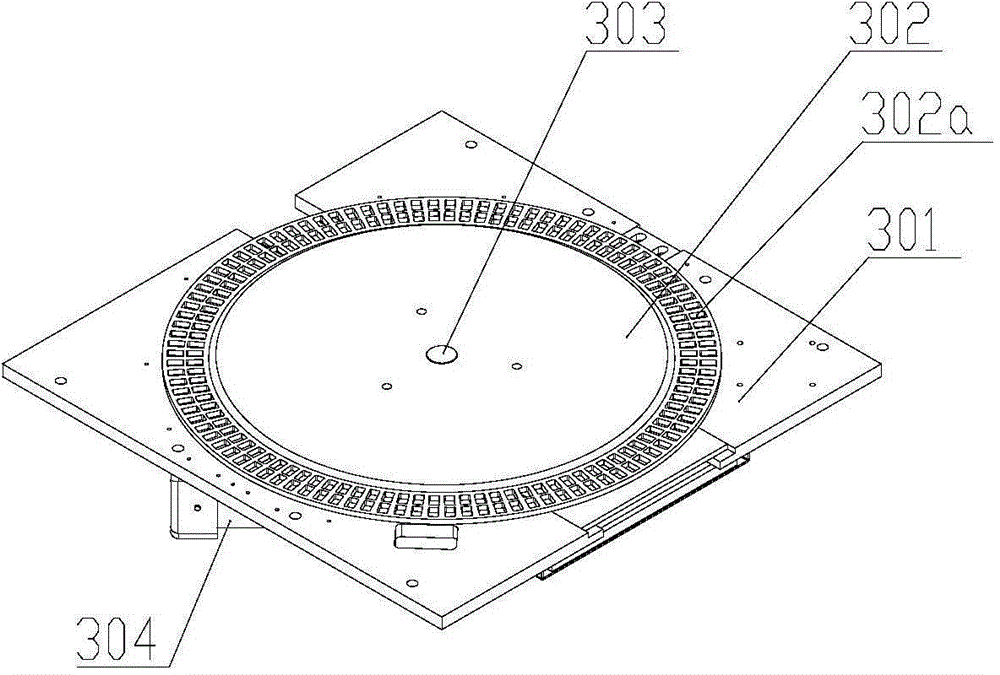

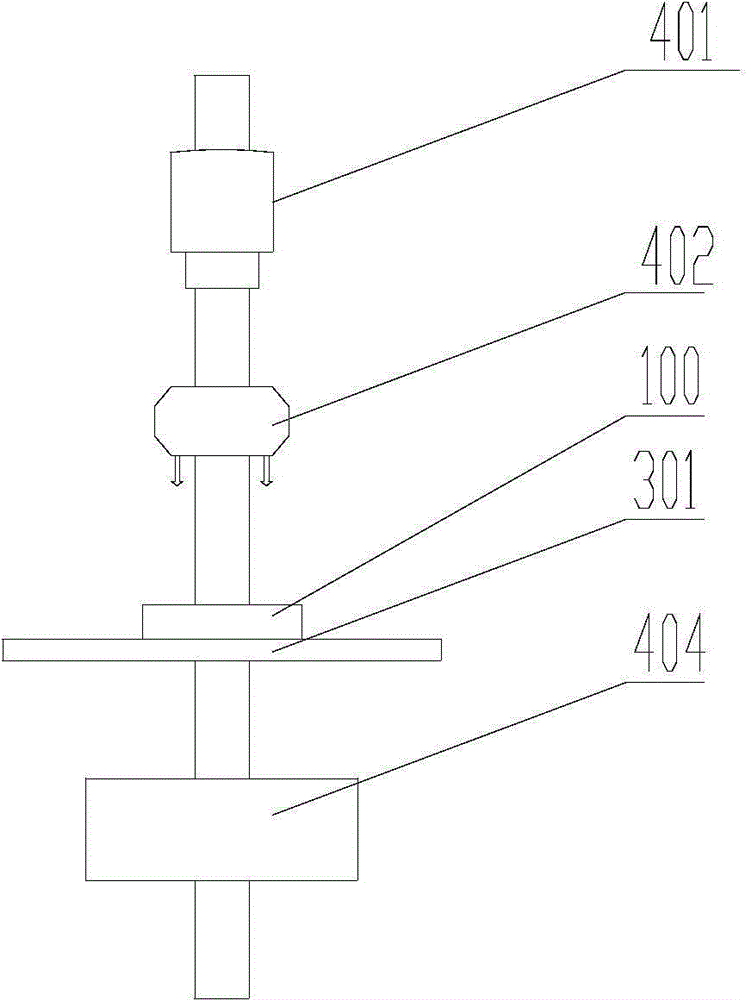

[0026] Embodiment 1, Figure 1 to Figure 6 A capsule detection method and a high-speed automatic detection device are given.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a detection method of soft capsules. The detection method comprises the following steps: recording 360-degree rolling of soft capsules by using color camera equipment, and then recording 360-degree rolling of the soft capsules by using monochrome camera equipment; analyzing whether colors of the soft capsules are qualified according to color images recorded by the color camera equipment, and analyzing whether appearances of the soft capsules are qualified according to monochrome images recorded by the monochrome camera equipment; removing the soft capsules of which the colors and the appearances are synchronously qualified as qualified products; and removing the soft capsules of which the colors or the appearances are unqualified or both the colors and the appearances are unqualified as unqualified products.

Description

technical field [0001] The invention relates to a detection method for detecting defects of soft capsules and sorting qualified soft capsules and defective soft capsules and a high-speed automatic detection device. Background technique [0002] In the prior art, defects such as shape deviation, size deviation, color difference, air bubbles, and stains inevitably exist in the production process of soft capsules, and these soft capsules with defects must be screened out and eliminated. At present, manual visual inspection is basically used to sort out defective products. The soft capsules are poured into the hopper and dispersed onto the frosted glass table with backlight. The inspector uses naked eyes to check the soft capsules on the backlight table to pick out the defective soft capsules. The working status of the inspectors has a great influence on the detection effect, and this working method has low detection efficiency, high cost and high labor intensity. It is easy t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/95

Inventor 晏毓孙庆海

Owner HANGZHOU QOGORI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com