Online high-speed railway steel rail damage monitoring method

A rail and high-speed rail technology, applied in the field of high-speed rail damage detection, can solve the problems of low detection speed and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with the accompanying drawings, the specific implementation of the online monitoring method for high-speed rail damage is described as follows:

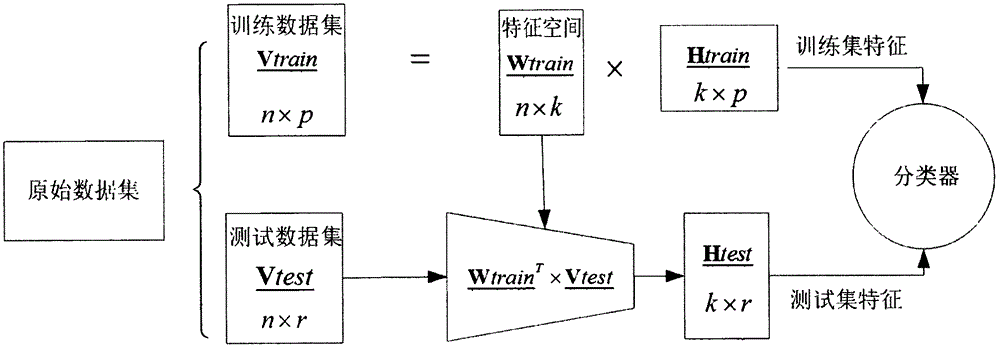

[0050] figure 1 It is a diagram of the main steps of the on-line monitoring method for rail damage in high-speed rail. By building models for high-speed rail and high-speed rail cars, typical rail vibration signals can be obtained, and a representative data set of rail damage vibration signals can be established. The number of vibration signal samples for each sample is 3724, and the entire data set has a total of 300 samples, where the lossless signal has 100 samples, and the typical damaged signal has 200 samples in total. In order to judge whether there is damage, 80 non-destructive samples and 160 damaged samples are selected here to form the training set, while the test set is composed of 20 non-destructive samples and 40 damaged samples.

[0051] First, a low-pass filter is applied to the vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com