Gas purification method

A technology of gas purification and gas purification device, applied in the field of purification, to achieve the effects of protecting the ecological environment, reducing emissions, and huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

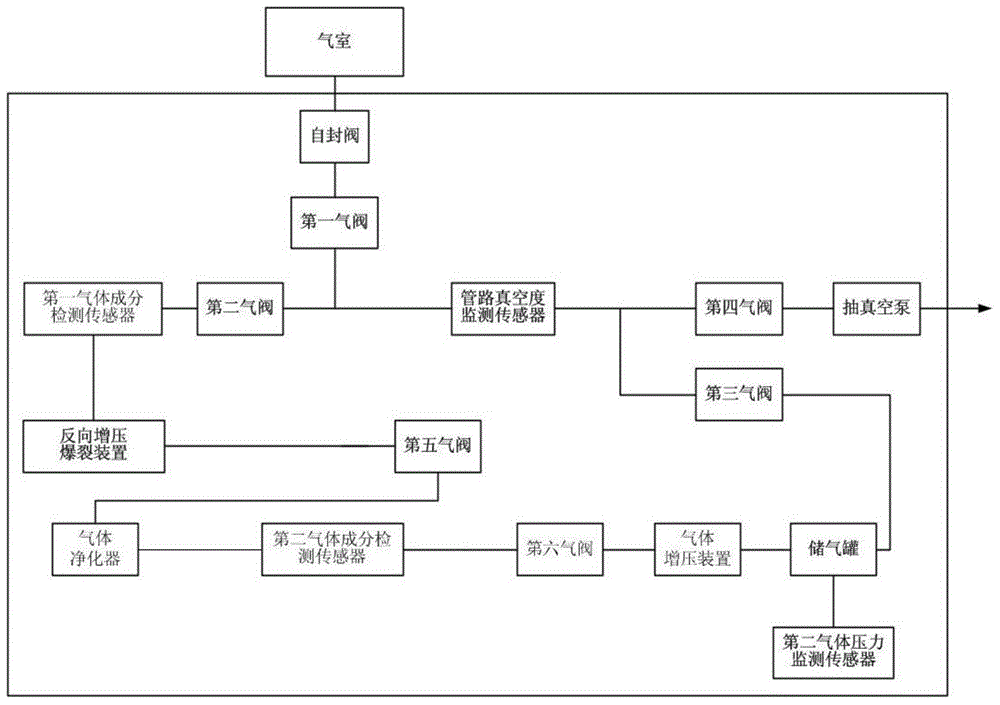

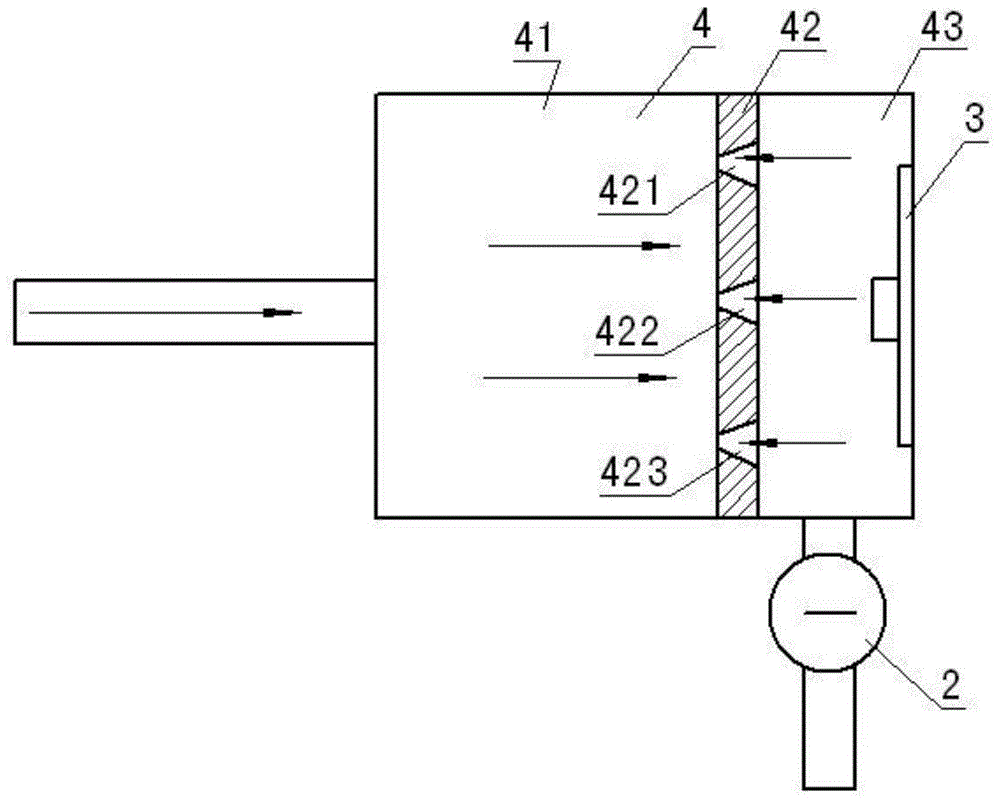

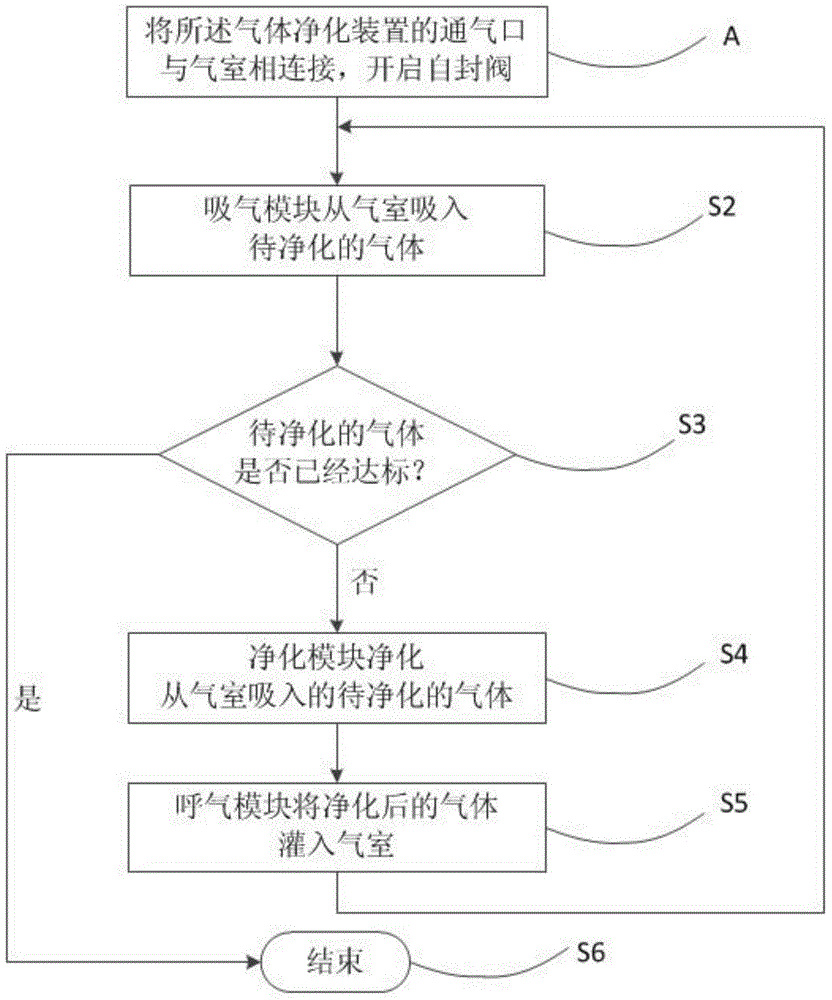

[0027] The gas purification device of the present invention includes a vent port for connecting the air chamber, and the vent port is provided with a self-sealing valve; it also includes a main ventilating pipeline, an inhalation module, a purification module and an exhalation module; the vent port is arranged on the The head end of the main ventilation pipeline is connected to the head end of the inhalation module and the end of the exhalation module at the end of the main ventilation pipeline, the end of the inhalation module is connected to the head end of the purification module, and the end of the purification module is connected to the exhalation module. The heads of the modules are connected.

[0028] A first air valve may be arranged on the main ventilation line.

[0029] The inhalation module includes an inhalation pipeline, and a second air valve is arranged on the inhalation pipeline.

[0030] A first gas component detection sensor is arranged on the main ventilati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com