Heat radiation device

A heat dissipation device and heat sink technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of reduced heat dissipation demand, low memory module, waste of air volume, etc., and achieve the effect of optimizing air flow management, saving parts cost, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

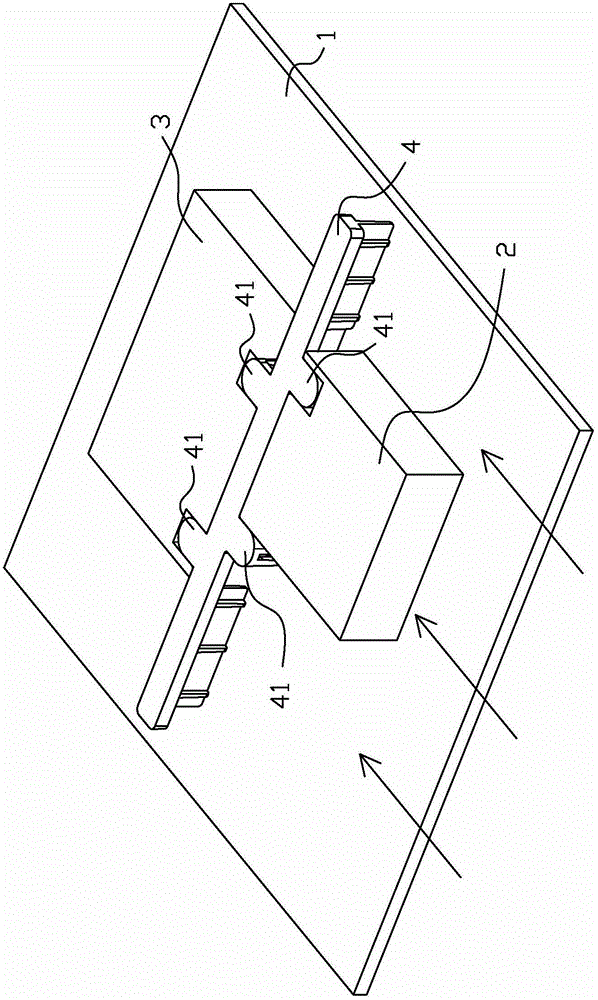

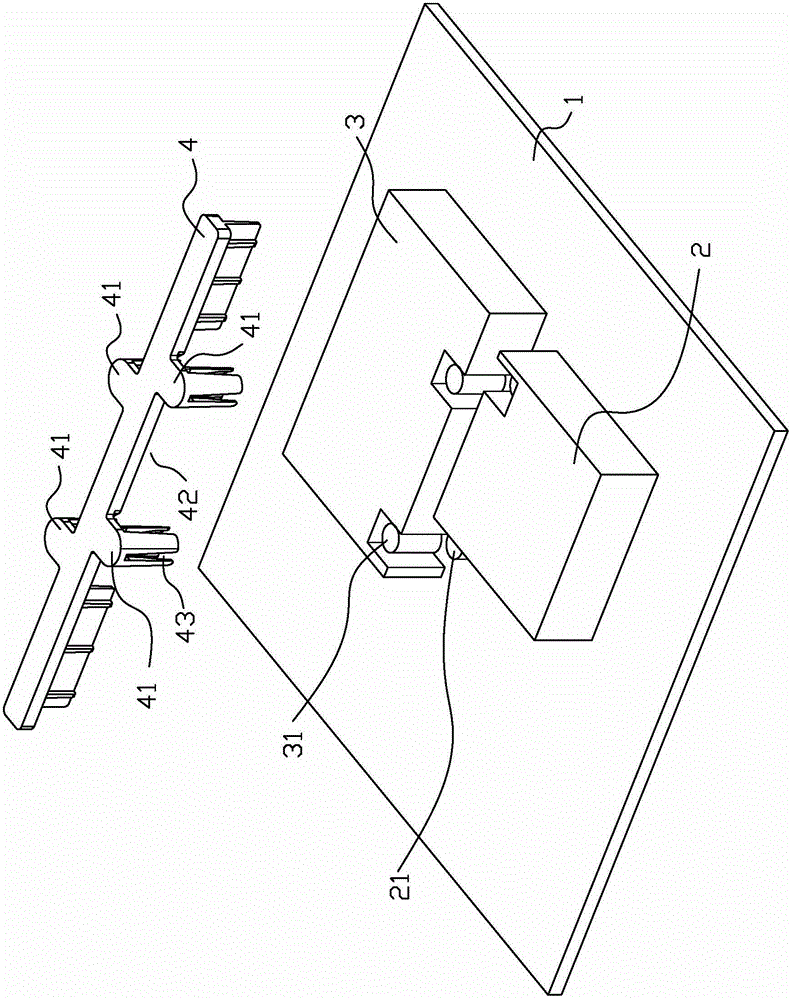

[0012] see figure 1 As shown, a heat dissipation device of the present invention, in this embodiment, is applied in a multi-node server to dissipate heat for its internal electronic components. , memory and other electronics need heat dissipation elements to dissipate heat, and a fan (not shown) is arranged at one end of the motherboard 1 to take away the heat generated by the electronic components on the motherboard 1 by accelerating the air flow.

[0013] In the present invention, the heat dissipation device includes a first radiator 2 , a second radiator 3 , and a windshield 4 .

[0014] The first heat sink 2 is fixed on the main board 1 through the fixing member 21 and is located in the airflow direction of the fan, and is used for heat dissipation of an electronic component with a high heat dissipation requirement, such as a CPU.

[0015] The second heat sink 3 is fixed on the main board through the fixing member 31 and is located in the wind flow direction of the fan. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com