Sedum plant vertical soilless greening system

A vertical greening and plant technology, applied in soilless cultivation, botanical equipment and methods, gardening, etc., can solve the long-term demand, need several years of growth, can not achieve long-term multi-year use, secondary pollution of the surrounding environment, etc. problems, to achieve the effect of less pests and diseases, easy replacement, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

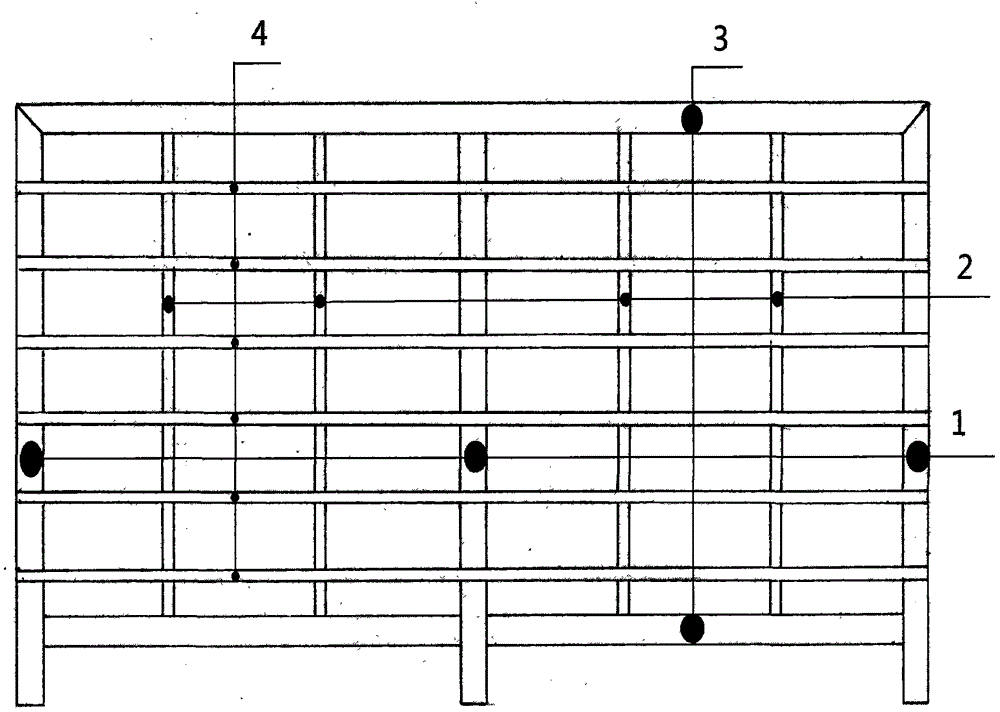

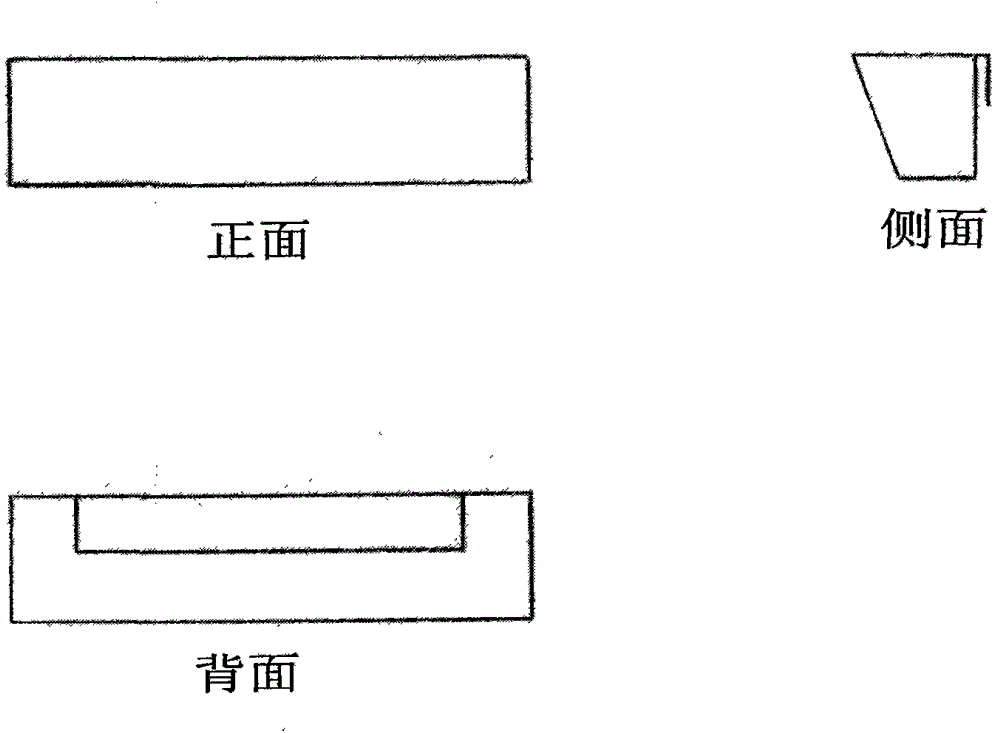

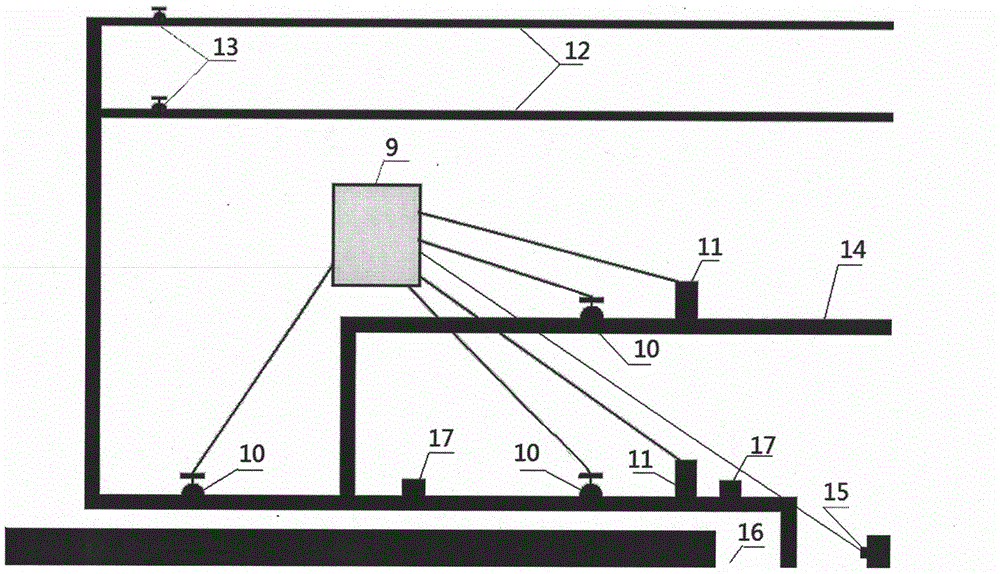

[0020] 1. Sedum plant vertical soilless greening fixture ( figure 1 ): The fixing device is composed of longitudinal keel (1, 2) and transverse keel (3, 4). Soil greening fixtures are firm and safe to use. The longitudinal keels (1, 2) are divided into longitudinal main keels (1) and longitudinal auxiliary keels (2). The material is 40mm×40mm--200mm×200mm square steel pipe, channel steel or angle iron, and the material of the longitudinal auxiliary keel (2) is 20mm×20mm--80mm×80mm square steel pipe, channel steel or angle iron. The same transverse keel (3, 4) is also divided into a transverse main keel (3) and a transverse auxiliary keel (4). ) The material is 40mm×40mm--200mm×200mm square steel pipe, channel steel or angle iron, and the horizontal auxiliary keel (4) is made of 20mm×20mm--80mm×80mm square steel pipe, channel steel or angle iron, and the horizontal auxiliary keel (4 ) is welded with a slide rail, and the material of the slide rail is 30mm×30mm--40mm×40mm ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com