Laser atomization device

An atomizing device and laser technology, applied in the application, tobacco, smoker's products and other directions, can solve the problems of high power consumption, low atomization efficiency, uneven heating of the heating wire, etc., to simplify the structure, reduce power consumption, Overcoming the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

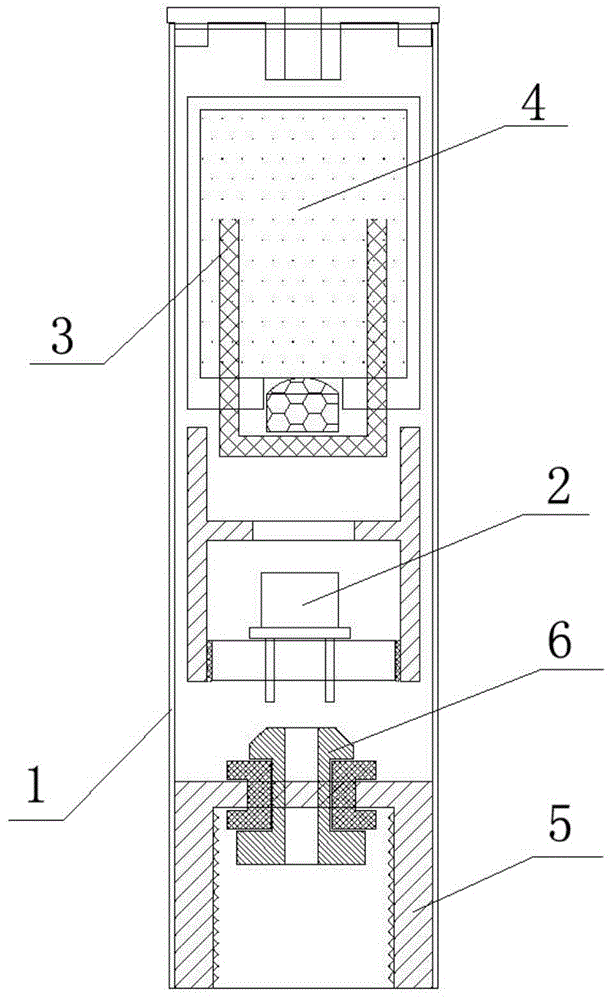

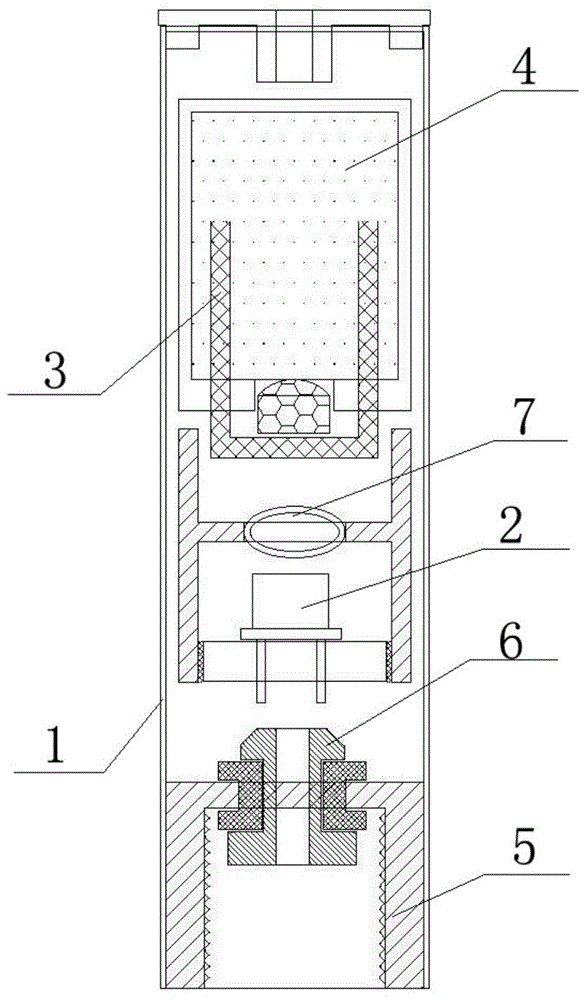

[0018] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0019] Such as figure 1 As shown, the present invention provides a laser atomization device, which includes a housing 1, a laser generator 2 and a liquid guide fiber 3 arranged opposite to the laser generator 2 are arranged in the housing 1, so that The laser generator 2 is also connected with a power source (not shown) for driving the laser generator 2 , and the liquid guide fiber 3 is in contact with the atomized liquid in the atomized liquid carrier 4 .

[0020] The laser at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com