Filter element structure easy to replace

An easy-to-replace, filter element technology, applied in filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of increasing the service life of filter material, material waste, increasing use cost, etc., to save materials, replace Accurate timing and consistent longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

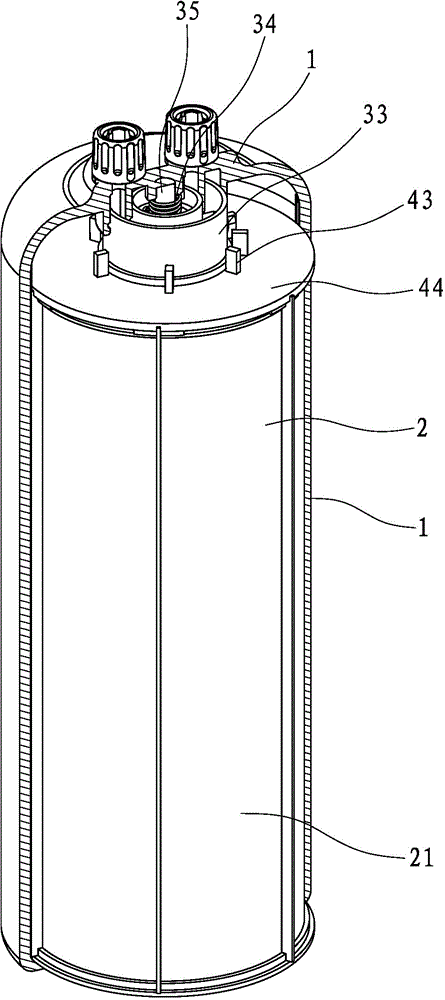

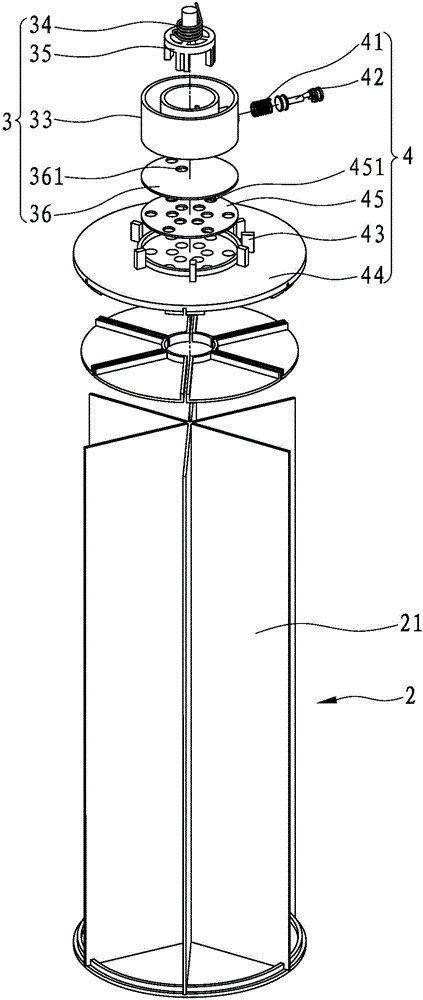

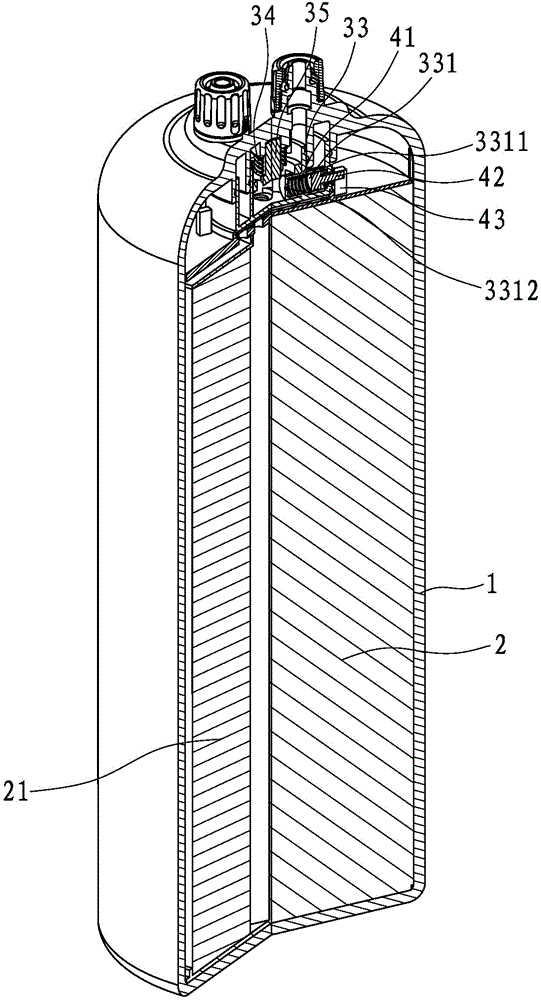

[0043] refer to Figure 1 to Figure 4 As shown, an easily replaceable filter element structure disclosed by the present invention includes a filter element housing 1 , a filter element body 2 , a water diversion rotating mechanism 3 and a water pressure stop mechanism 4 .

[0044] The filter element main body 2 is installed in the filter element housing 1. The filter element main body 2 is composed of a plurality of filter element interlayers 21. Each filter element interlayer 21 is respectively provided with a water inlet hole 211 and a water outlet hole 212. The water inlet hole 211 is connected to the filter element interlayer 21. The water passage 213 communicates, and the water outlet hole 212 communicates with the drainage channel 214 of the filter element interlayer 21 .

[0045] The water diversion rotating mechanism 3 is rotatably m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com