Vertical intelligent high-pressure rotor assembly device with elastic structure

A high-pressure rotor and equipment technology, applied in the field of high-pressure rotor intelligent assembly equipment, can solve the problems of not being able to meet the needs of five-degree-of-freedom movement and the inability to intelligently assemble high-voltage rotors, and achieve reduced deformation, small external forces, and improved assembly. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

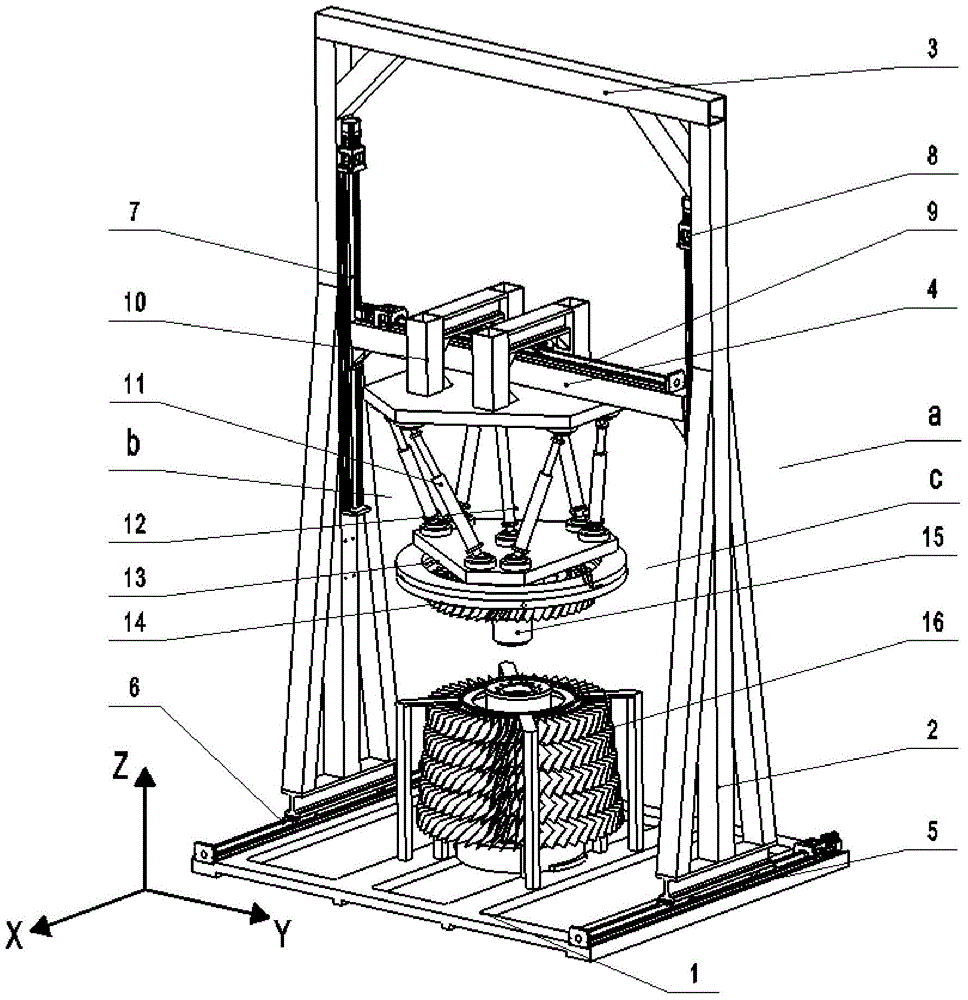

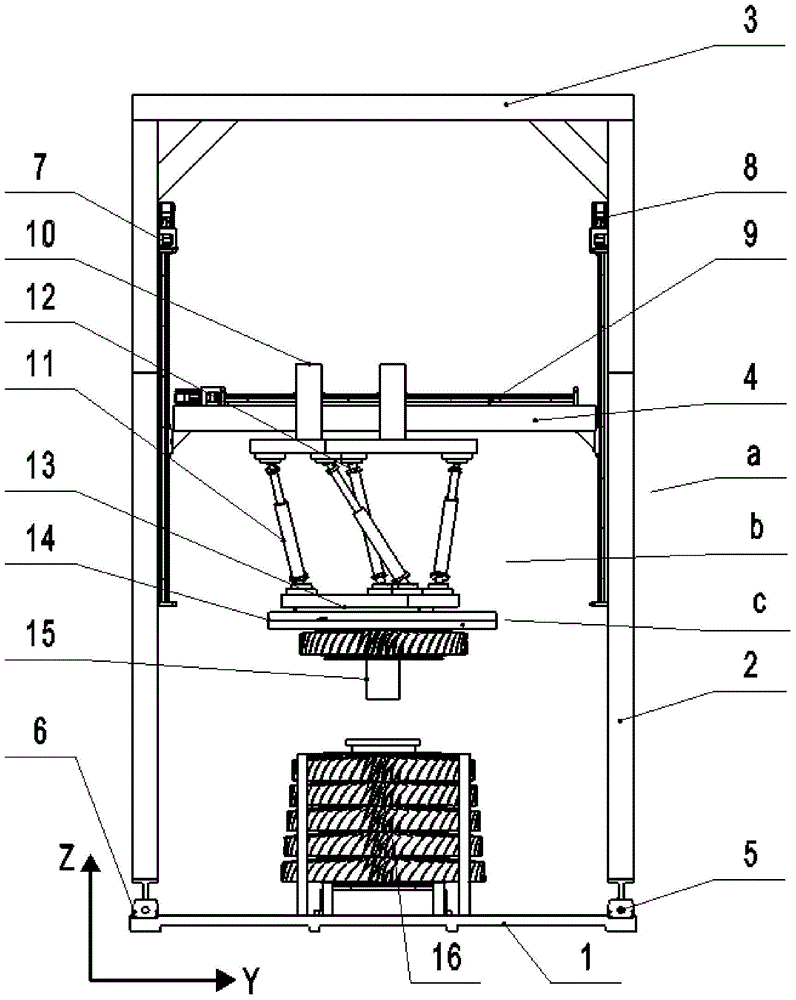

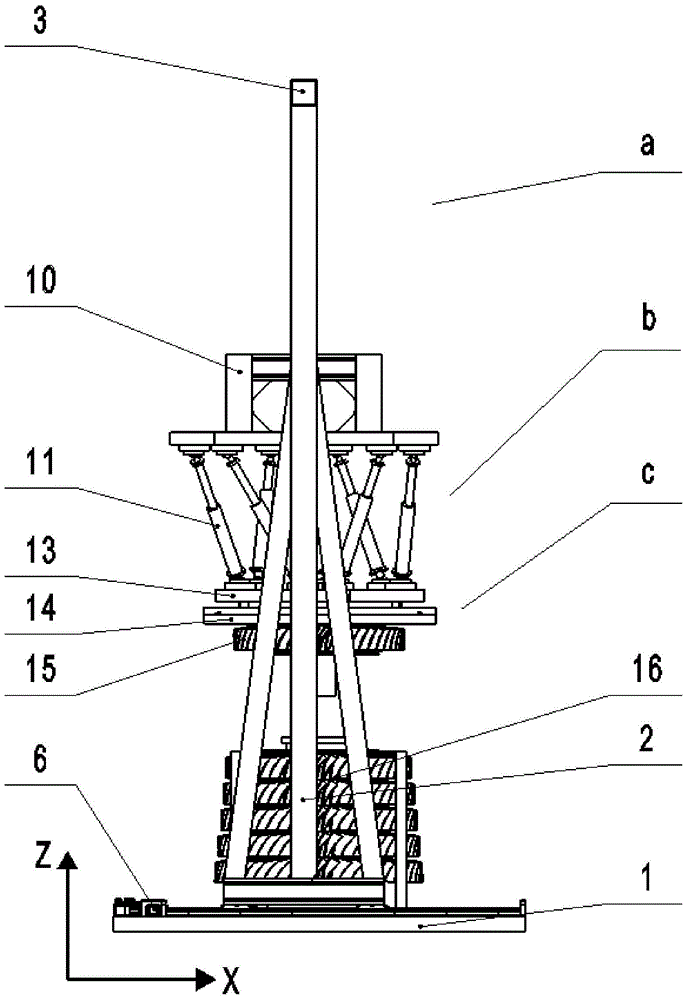

[0022] like Figure 1-4 As shown, this embodiment includes: a three-degree-of-freedom gantry-type active movement mechanism a, a five-degree-of-freedom parallel passive movement mechanism b, and a rotor fixture c, wherein: a five-degree-of-freedom parallel passive movement mechanism b is slidably arranged on a three-degree-of-freedom gantry On the active motion mechanism a, the rotor fixture c is fixedly arranged on the moving platform of the five-degree-of-freedom parallel passive motion mechanism b.

[0023] In this embodiment, the three-degree-of-freedom gantry active movement mechanism a includes: an X-axis moving base 1 , a vertical support frame 2 , a top beam 3 , and a middle moving beam 4 . Wherein: the vertical support frame 2 is slidably connected with the X-axis moving base 1, the middle moving beam 4 is slidably connected with the vertical support frame 2, and the top beam 3 is fixedly connected with the vertical support frame 2.

[0024] like Figure 1-Figure 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com