Tidying tool of injection molding parts

A technology for injection molding parts and tools, applied in the field of injection molding parts finishing tools, can solve the problems of rising production costs, complicated equipment, and laboriousness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

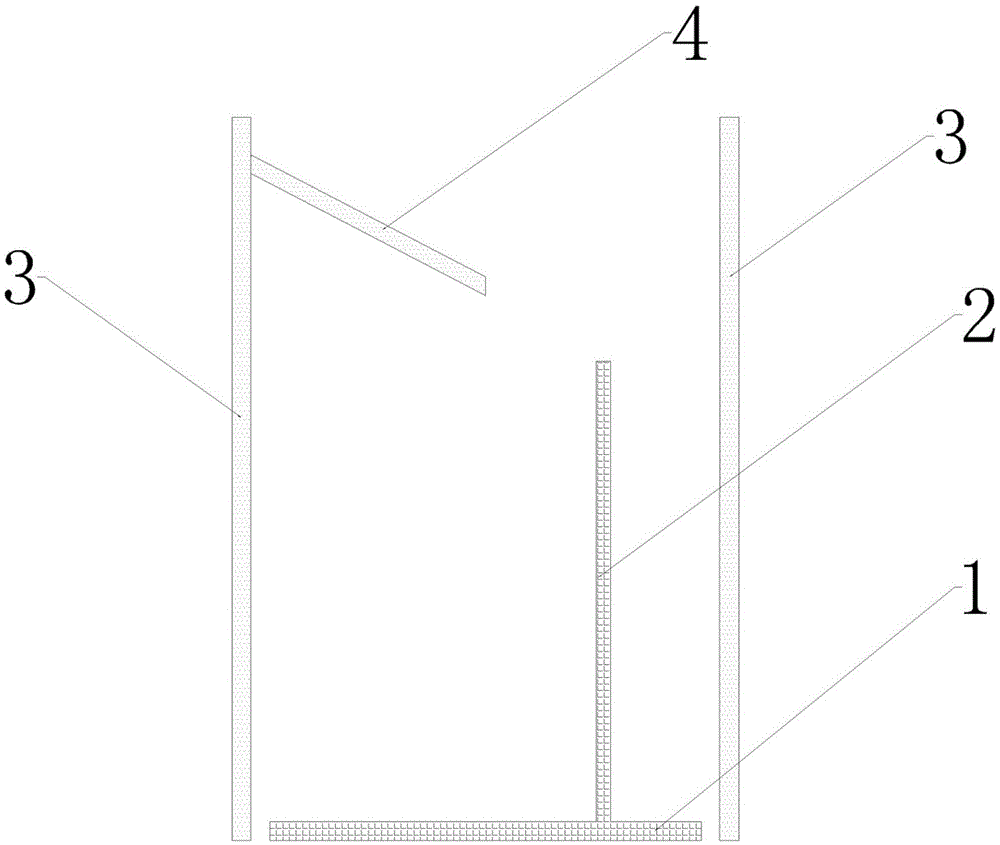

[0012] according to figure 1 The shown finishing tool for injection molded parts has a base 1, a needle 2, a bracket 3, and a slide 4. The base 1 is placed horizontally at the exit of the injection molding machine, and the needle 2 is vertically fixed on the base 1. The described The bracket 3 is separated from the base 1 and is placed around the base 1 . The upper wall of the bracket 3 has a slide 4 .

[0013] Here if the injection molded part is a disc with a hole shape, then the support can be set to a cylindrical barrel shape.

[0014] When in use, the injection molded part slips from the exit of the injection molding machine, first falls on the landslide 4, slides down along the slope of the landslide 4, and then the injection molded part falls on the threading needle 2, and then falls to the base along the threading needle 2 1 above.

[0015] In such a cyclical operation, the injection molded parts will pass through the threading needle 2 one by one and neatly stacked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com