Acridine derivatives, and preparation method and application thereof

A derivative, acridine technology, applied in the field of organic electroluminescence, can solve the problems of increasing the complexity of the device manufacturing process, reducing the cost of OLED, disadvantages, etc., and achieve good electron acceptance ability, high Tg, high glass transition temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

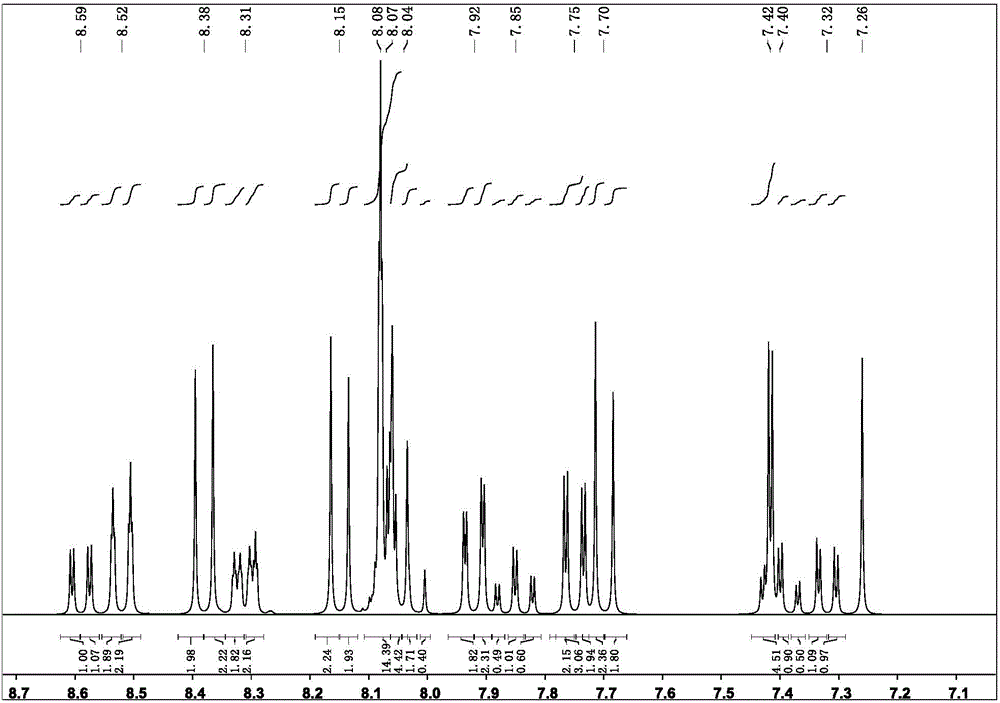

Embodiment 1

[0030] Synthesis of parent 2,7-dibromo-9-phenylacridine (reference: Org.Biomol.Chem., 2010, 8, 326-330)

[0031]

[0032] Two (4-bromophenyl) amine 26.2g (molecular weight 327, 0.08mol), benzoic acid 9.8g (molecular weight 122, 0.08mol), ZnCl 2 Use 16.1g (molecular weight: 134, 0.12mol) and heat in a sand bath for 5 hours while stirring at a temperature of 240-260°C. Cool, dissolve, mix with silica gel, and separate by column (eluent: dichloromethane / ethyl acetate=20:1) to obtain 18.2 g of product with a yield of 55% and a molecular weight of 413.

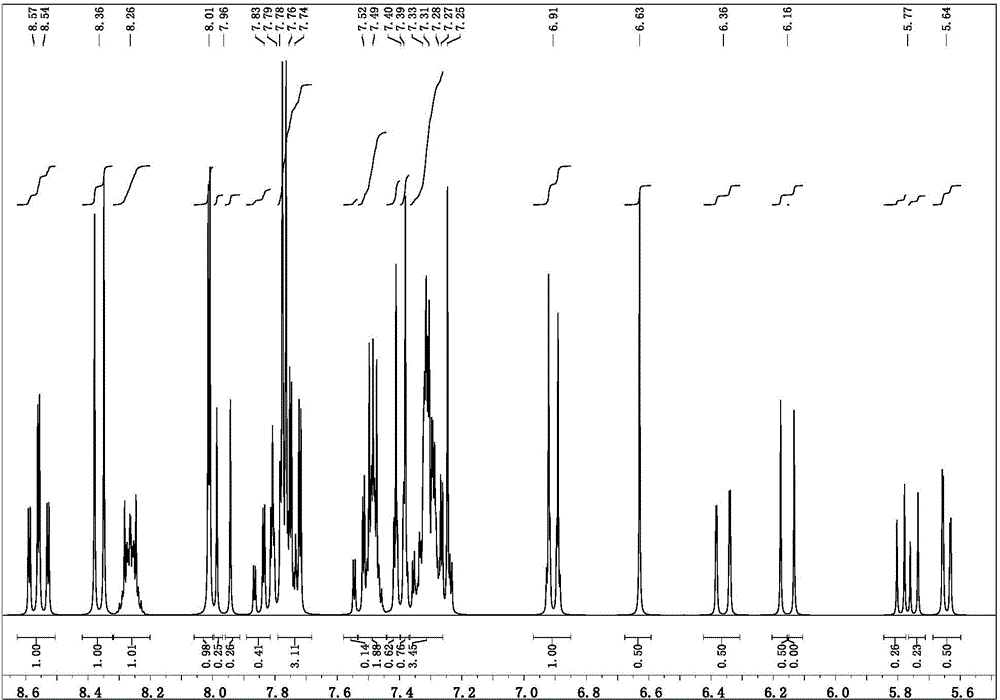

Embodiment 2

[0034] Synthesis of parent 2,7-dibromo-9-(pyridin-2-yl)acridine

[0035] The synthesis steps are the same as the previous 1, except that benzoic acid is changed to 2-naphthoic acid, and other reagents remain unchanged to obtain the target parent 2,7-dibromo-9-(pyridin-2-yl)acridine. The reaction pathway is as follows:

[0036]

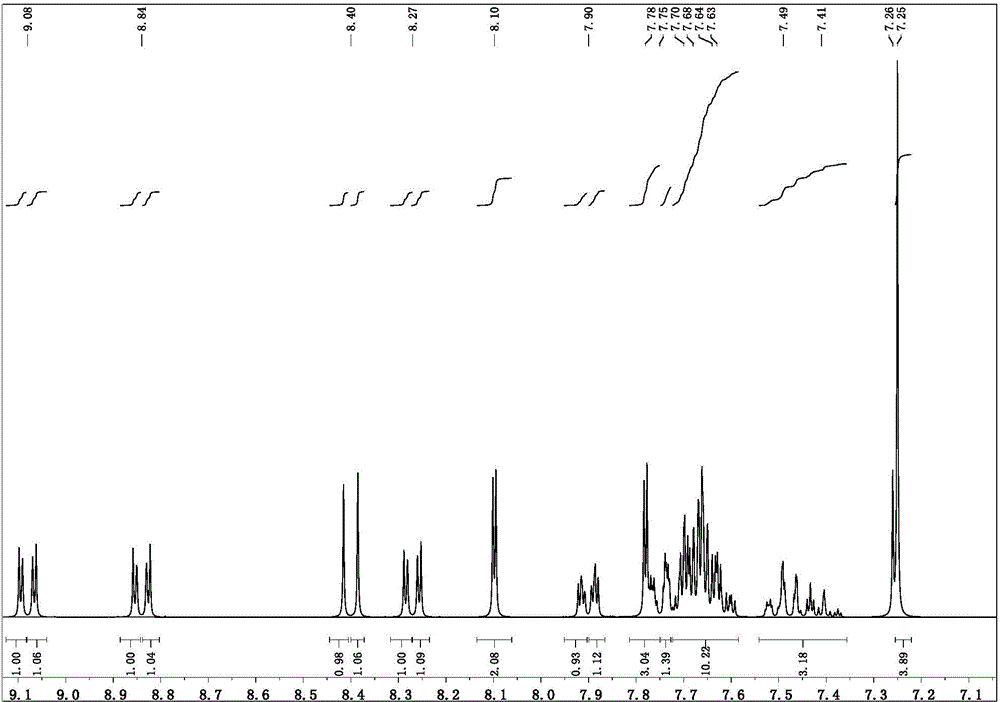

Embodiment 3

[0038] Synthesis of parent parent 2,7-dibromo-9-(quinolin-2-yl)acridine

[0039] The synthesis steps are the same as the previous 1, except that benzoic acid is changed to 2-naphthoic acid, and other reagents remain unchanged to obtain the target parent 2,7-dibromo-9-(quinolin-2-yl)acridine. The reaction pathway is as follows:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com