Light-enhanced supercapacitor electrode material and all-solid-state supercapacitor and preparation thereof

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes and hybrid capacitor electrolytes, can solve the problems that complex systems are difficult to put into large-scale production and use, and light-enhanced supercapacitors cannot work for a long time, so as to improve charge and discharge efficiency and solve Unable to work for a long time, the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment discloses the preparation of an electrode material for a light-enhanced supercapacitor, and the preparation process is as follows:

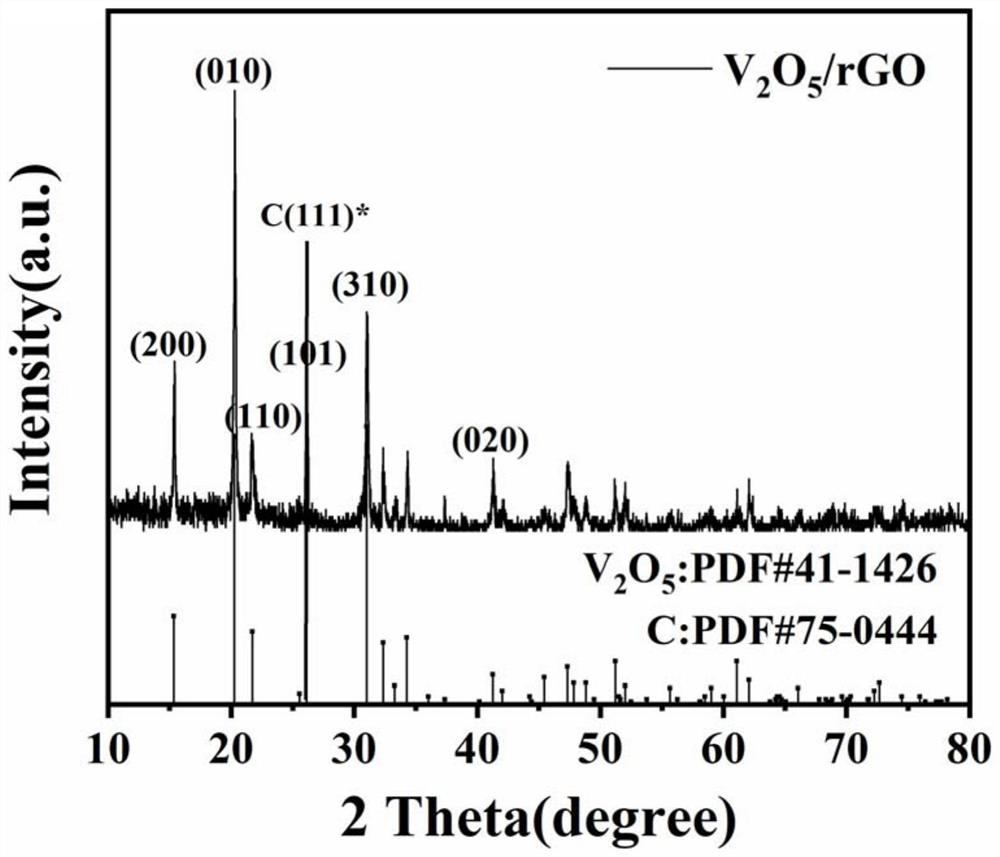

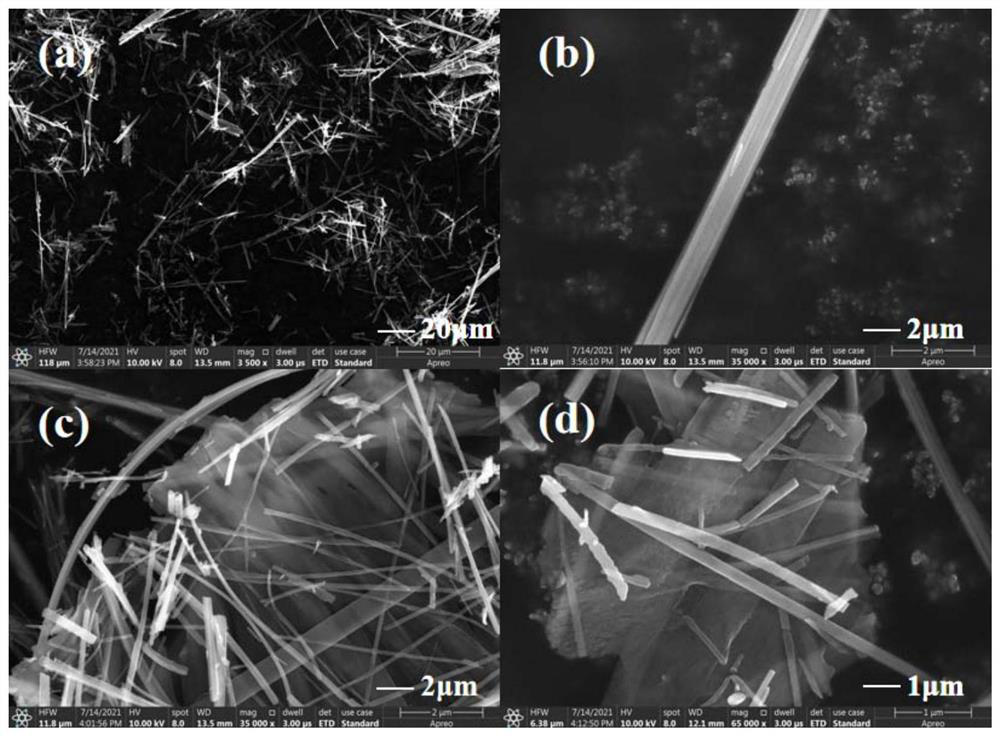

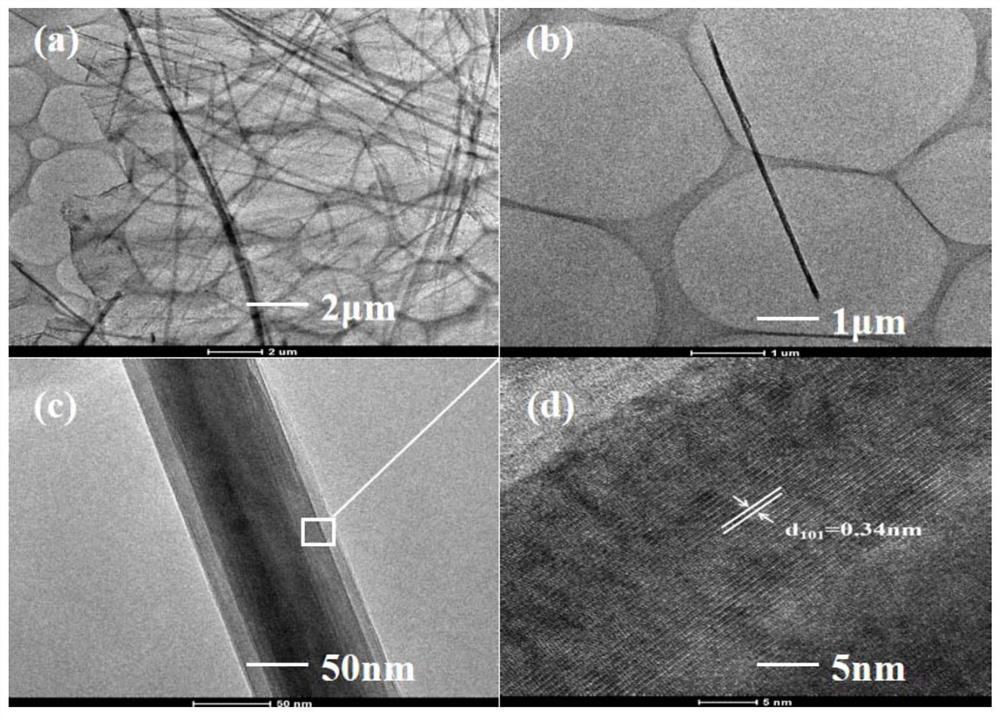

[0051] Dissolve 0.365g vanadium pentoxide powder in deionized water, and after ultrasonication, form a vanadium pentoxide aqueous solution with a concentration of 0.067mol / L, add 30% hydrogen peroxide to the vanadium pentoxide aqueous solution and continue ultrasonication to form a mixed Liquid, wherein the volume ratio of vanadium pentoxide aqueous solution to hydrogen peroxide is 1:6; then add 0.061g graphene oxide to form a precursor solution. The precursor solution was poured into a hydrothermal kettle, heated at 205°C for 48 hours, and annealed at 350°C for 2 hours in an air environment in a tube furnace to obtain vanadium pentoxide / reduced graphene oxide powder.

[0052] The vanadium pentoxide / reduced graphene oxide powder was dispersed in isopropanol to obtain a composite material dispersion, wherein the vanadium pen...

Embodiment 2

[0055] This embodiment provides a light-enhanced symmetrical all-solid-state supercapacitor, whose structure is as follows: Figure 4 As shown, including the gel electrolyte layer 1 in the middle, the electrode sheets symmetrically arranged on both sides of the gel electrolyte layer 1, the electrode sheets are the light-enhanced supercapacitor electrode materials prepared in Example 1, and the transparent conductive substrate 2 specifications of the electrode sheets 20mm*30mm*1.6mm, the area of the growing composite material film layer 3 is 20mm*20mm, and a 10mm blank conductive layer is reserved on the substrate for pasting the tabs 4 to lead out the soft case 5, the soft case 5 is made of aluminum The material of the plastic package is uniformly sealed around the soft package shell 5 with a plastic sealing machine to prevent the electrode sheet from being damaged in the air for a long time and affecting its normal use. An opening with an area of 8mm*8mm is reserved on on...

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is that the mass ratio of vanadium pentoxide powder to graphene oxide is 12:1.

[0061] The morphology of the vanadium pentoxide / reduced graphene oxide composite film in the light-enhanced supercapacitor electrode material prepared in this example is almost the same as that of the film prepared in Example 1.

[0062] According to the method of Example 2, the light-enhanced supercapacitor electrode material prepared in this example was used as an electrode sheet to prepare a light-enhanced symmetrical all-solid-state supercapacitor. according to Figure 9 It can be seen from the capacitance performance gain curve shown that the capacitance gain ratio of this embodiment is slightly lower than that of Embodiment 2 under the same lighting conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com