System and method for treating exhaust gas

A technology for exhaust pipes and catalytic converters, which is applied in exhaust gas treatment, diagnostic devices for exhaust gas treatment devices, exhaust devices, etc., and can solve large spaces, HC and CO emission faults, and inability to mix urea with exhaust gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

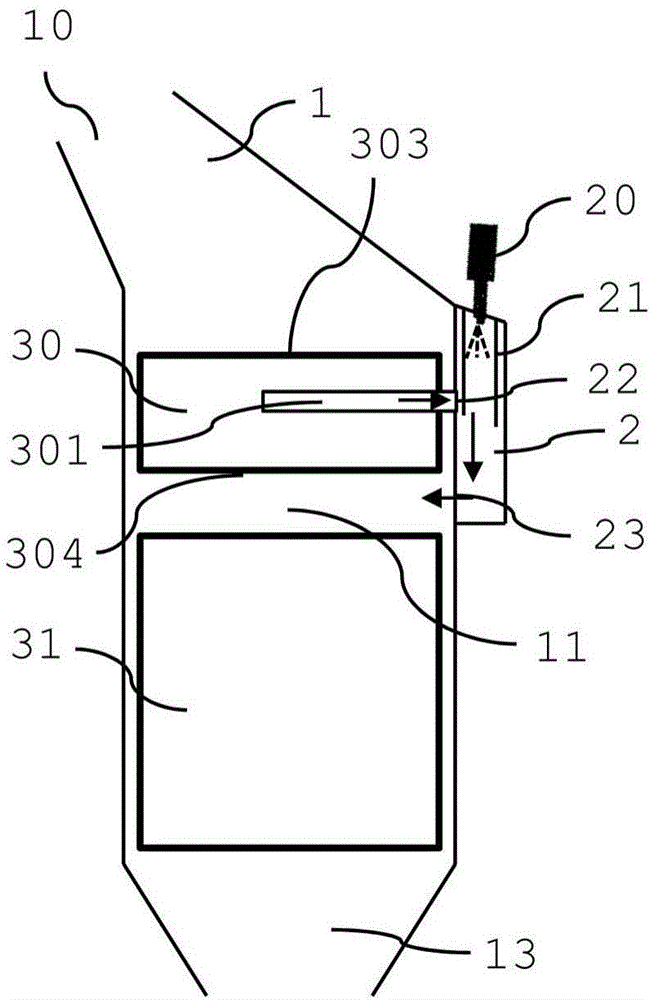

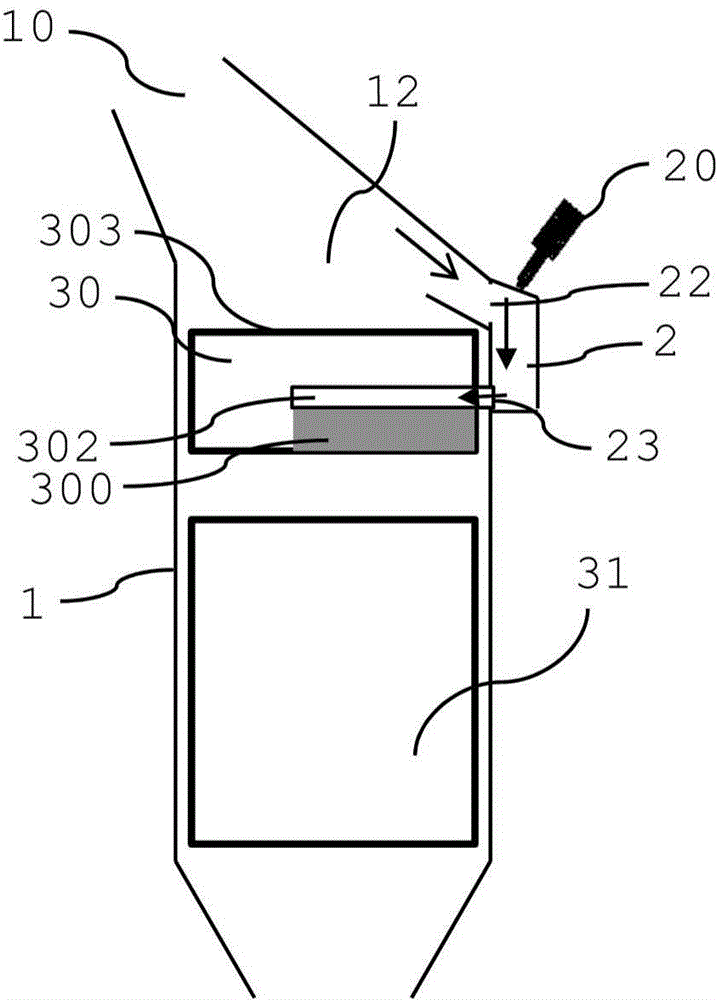

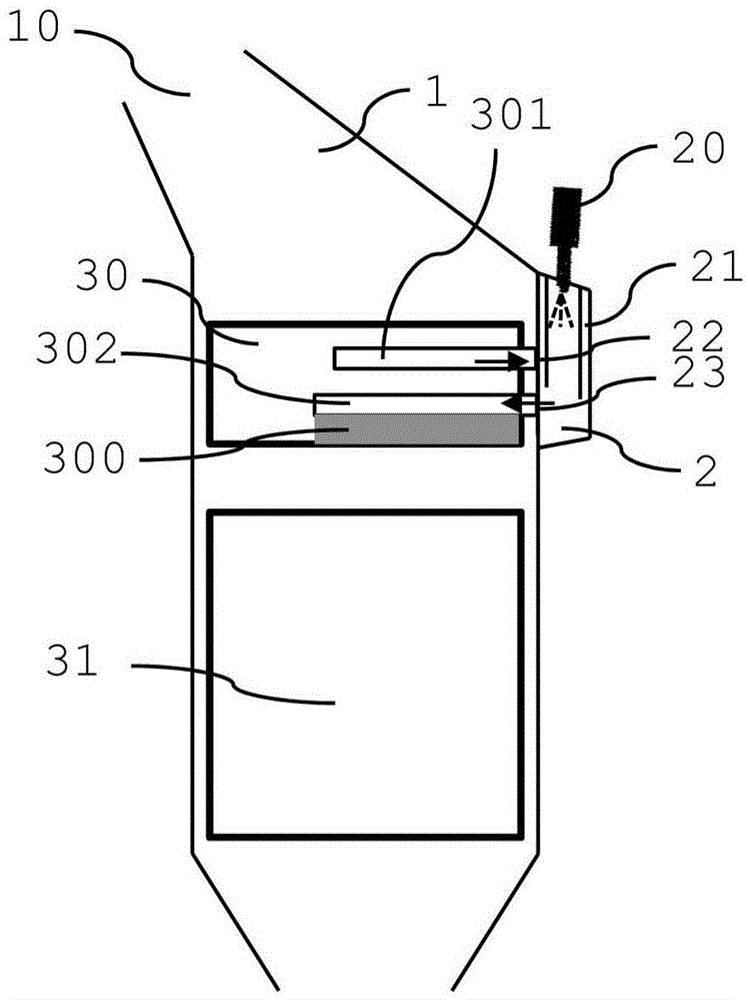

[0047] exist figure 1 Among them, the exhaust pipe inlet 10 is arranged at the upstream end of the exhaust pipe 1 . At the upstream end, the exhaust duct can be connected to the engine outlet. In the exhaust pipe 1 , an oxidation catalyst 30 such as a diesel oxidation catalyst (DOC) is arranged such that further downstream is a selective catalytic reactor (SCR) 31 . The SCR can, for example, also be combined with a diesel particulate filter (DPF) or be provided with a particulate filter function (SCRF). A bypass duct 2 with a bypass inlet 22 and a bypass outlet 23 is arranged adjacent to and substantially parallel to the exhaust duct 1 . The bypass pipe 2 bypasses a part of the exhaust pipe 1 and bypasses a part of the DOC 30, but not the entire DOC. The bypass pipe 2 is arranged on one side of the exhaust pipe 1 . However, the bypass duct can also be arranged to extend at least partially or completely around the circumference of the exhaust duct 1 . The bypass duct can bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com