Method for measuring void ratio of macadam mixture

A technology of mixture and porosity, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. The effect of short time, less error in measurement, and fewer test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

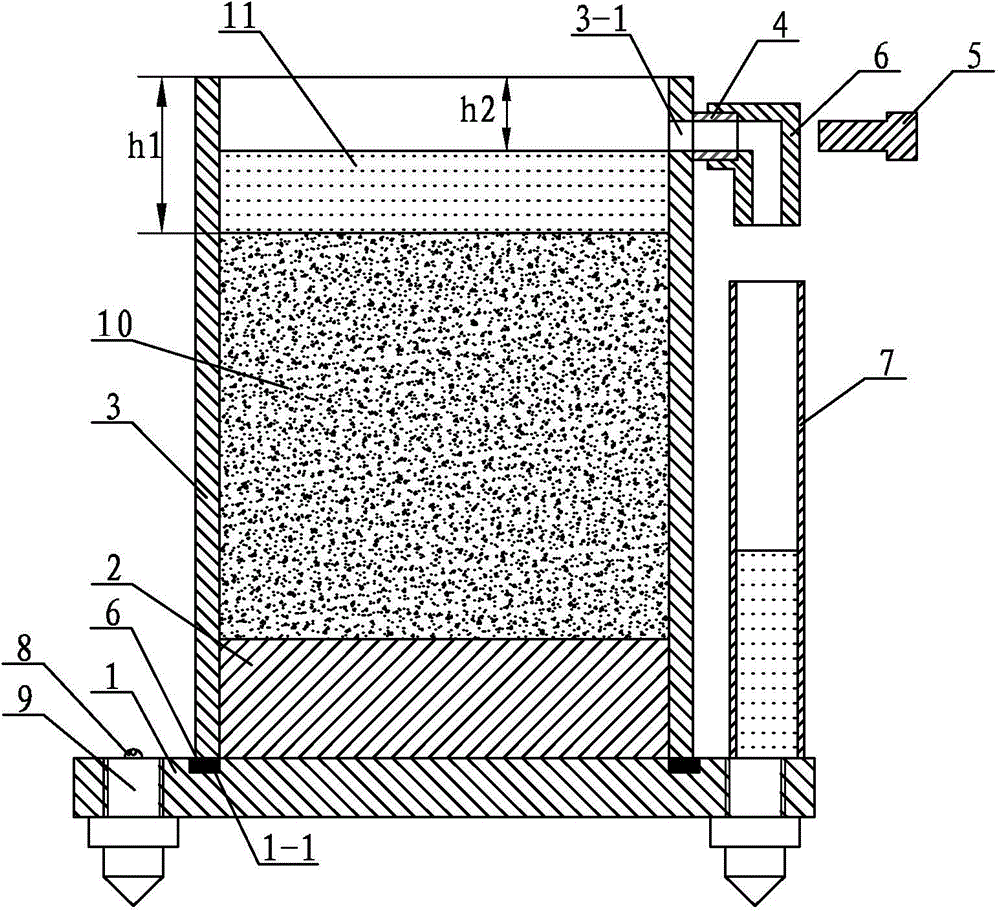

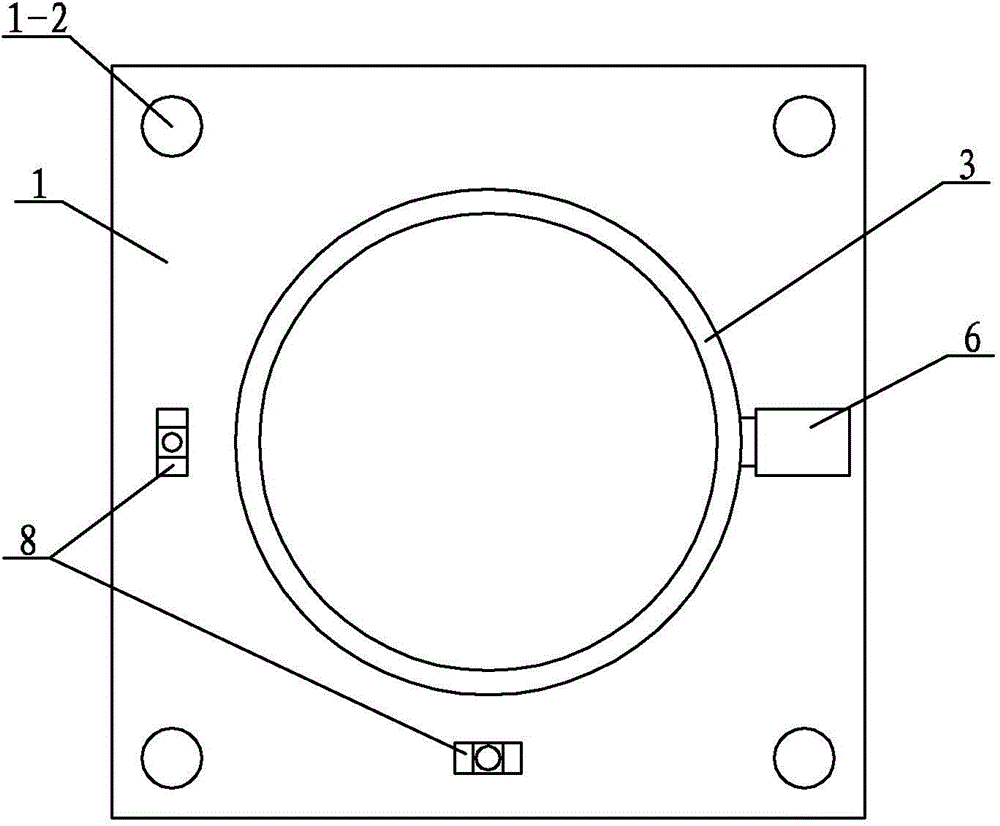

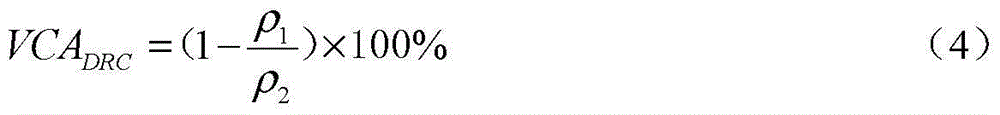

[0056] Specific implementation mode one: combine figure 1 and figure 2 Describe this implementation mode, this implementation mode is realized through the following steps:

[0057] Step 1: Put the crushed stone mixture 10 in a metal hanging basket, put the metal hanging basket into a container and soak in water for 24 hours, so that the open spaces of the crushed stone mixture are saturated with water;

[0058]Step 2: After checking that the measuring barrel 3 in the measuring device is leak-free, seal the water outlet 3-1 with the sealing valve 5, and remove the four foot screws 9;

[0059] Step 3, dry the water on the surface of the gravel mixture 10 with a wet towel, then put the saturated gravel mixture 10 into the measuring bucket 3, add 5ml to 10ml of water into the testing bucket 3, and the water The volume of V is denoted as V f1 , using a compaction instrument to vibrate the crushed stone mixture 10, and the compaction instrument is a prior art;

[0060] Step 4. ...

specific Embodiment approach 2

[0080] Specific implementation mode two: combination figure 1 To illustrate this embodiment, add 6ml of water into the test bucket 3 in step 3 of this embodiment. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0081] Specific implementation mode three: combination figure 1 To illustrate this embodiment, add 7ml of water into the test bucket 3 in step 3 of this embodiment. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com