Rigid cage guide defect detection method and detection method based on laser light screen scanning

A technology of laser light curtain and defect detection, which is applied in the direction of optical detection of defects/defects, can solve the problems of accuracy and reliability of data collected by sensors, manpower and production time, and affect the accuracy of tanks, etc., to achieve both The effect of reliability and convenience, wide applicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

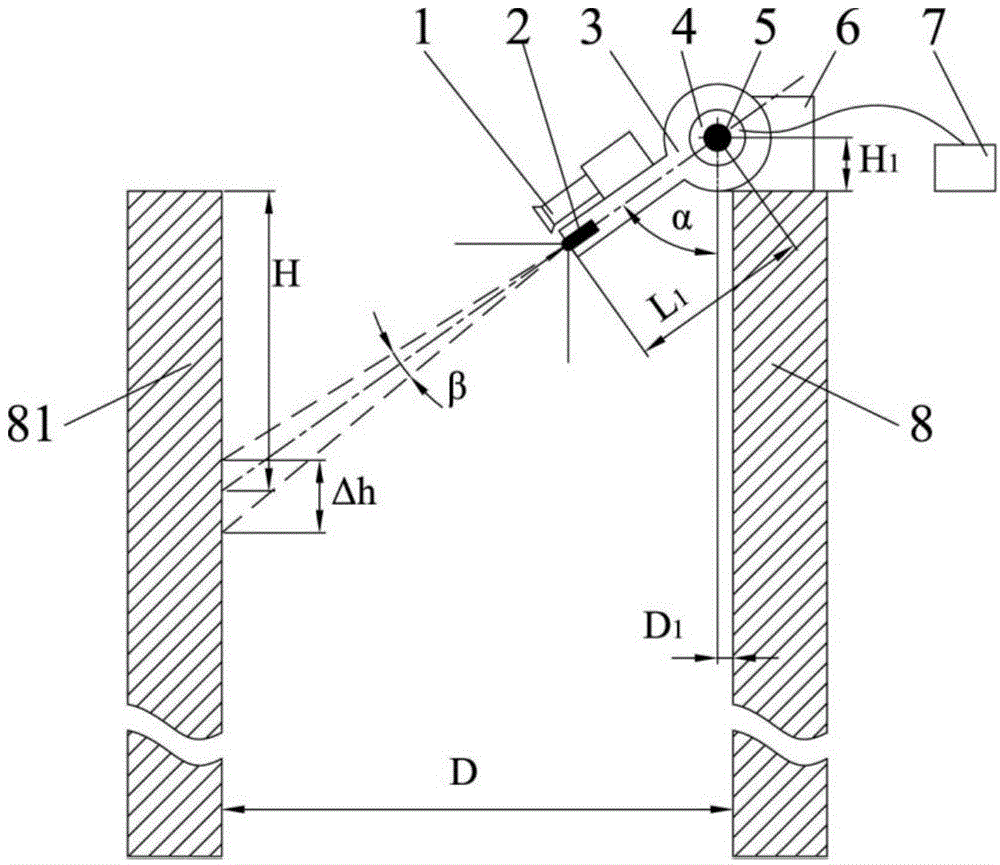

[0027] as attached figure 1 As shown, the rigid tank road defect detection device based on laser light curtain scanning includes a drive device 7, a rotating arm 3, an encoder 5, a laser 2 and a camera 1, and the rotating arm 3 is set on the second tank road through a support 6. 8 on the upper end surface and close to its inner surface, the rotating arm 3 and the support 6 are rotated through the shaft 4, the rotating arm 3 can rotate around the shaft 4, and is driven by the driving device 6, the shaft 4 An encoder 5 is arranged on the top, and a laser 2 and a camera 1 are arranged on the front of the rotating arm 3 . The laser 2 is arranged close to the camera 1 , and the laser emission direction of the laser 2 is consistent with the shooting direction of the camera 1 . The shaft center position of the shaft 4 protrudes out of the No. 2 tank channel 8, and the protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com