Optical anti-counterfeiting element and optical anti-counterfeiting product with same

An optical anti-counterfeiting and component technology, applied in optical components, optics, printed matter, etc., can solve the problems of high contrast requirements, low reliability, and unfavorable large-scale production of photosensitive adhesives, and achieve rich optical anti-counterfeiting features, high anti-counterfeiting ability, The effect of strong public attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The optical anti-counterfeiting element and the optical anti-counterfeiting product using the optical anti-counterfeiting element according to the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the drawings and detailed description are only descriptions of preferred embodiments of the invention and are not intended to limit the scope of the invention in any way.

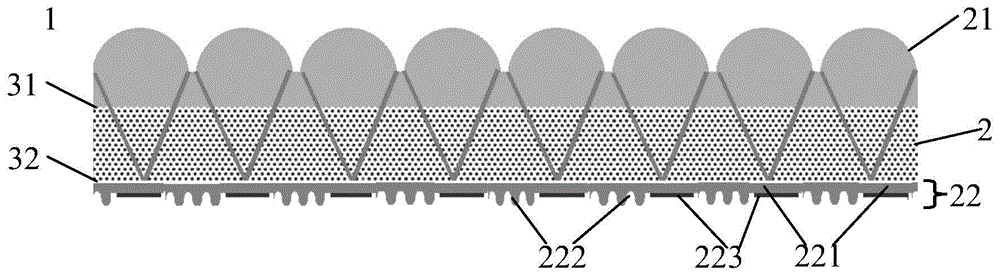

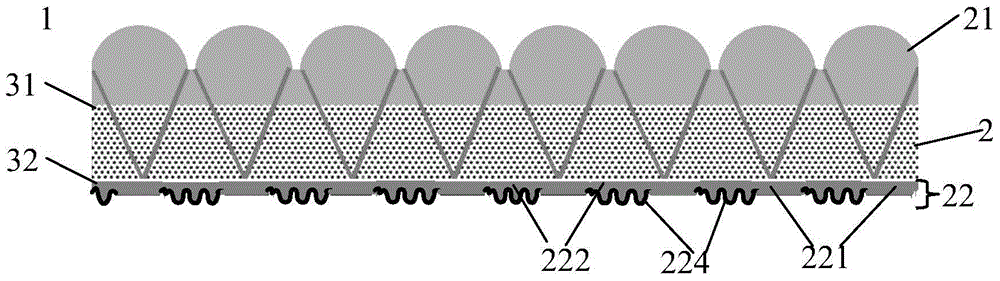

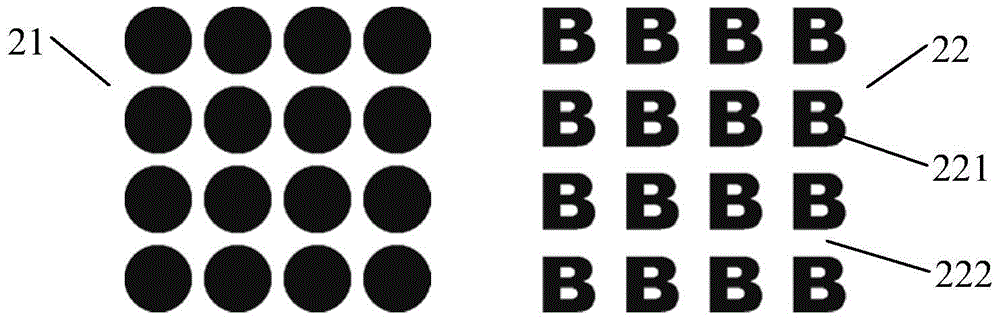

[0022] Such as Figure 1a and 1b As shown, the optical anti-counterfeiting element 1 according to one embodiment of the present invention includes: a substrate 2 including a first surface 31 and a second surface 32 opposite to each other; the first surface formed on the substrate 2 a sampling synthesis layer 21 on a surface 31; and a micro-image layer 22 formed on the second surface 32 of the substrate 2, the micro-image layer 22 comprising the second The first surface relief structure layer 221 and the second surface relief struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com