Vehicle controller

A controller and brake control technology, applied in general control systems, program control, computer control, etc., can solve the problems of shortening the service life of the motor, increasing the cost of use, high noise, etc. Soft, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

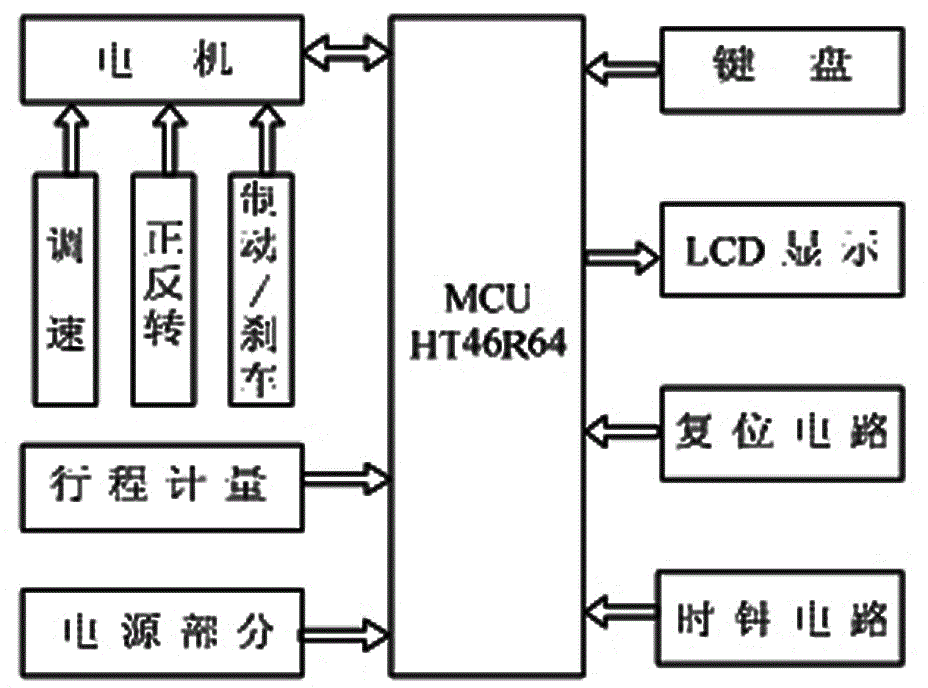

[0011] As shown in the figure, the present invention includes MCU, stroke measurement part, power supply part, speed regulation control part, forward and reverse control part, brake / brake control part, input keyboard, LCD display part, reset circuit, clock circuit, MCU respectively It is connected with stroke measurement part, power supply part, input keyboard, LCD display part, reset circuit, clock circuit and motor, and speed regulation control part, forward and reverse control part, brake / brake control part are respectively connected with motor.

[0012] The MCU adopts HT46R64 microprocessor.

[0013] The brake / brake control part adopts IR2132MOS tube.

[0014] The MCU adopts the HT46R64 microprocessor produced by Taiwan Holtek Company as the core of the system, together with some peripheral hardware and software to control the DC brushless motor, so as to realize the excellent performance of the controller. For example, through MCU instructions to control the forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com