Dust removing tool and dust removing method for cavity of IGBT module

A cavity and tooling technology, which is applied in the field of IGBT module cavity dust removal tooling and dust removal, can solve problems such as inability to ensure uniform and comprehensive cleaning, damage to the module shell, and increased packaging costs, so as to improve cleaning efficiency and cleaning effect. Avoid collision damage or man-made damage, reduce the effect of manufacturing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

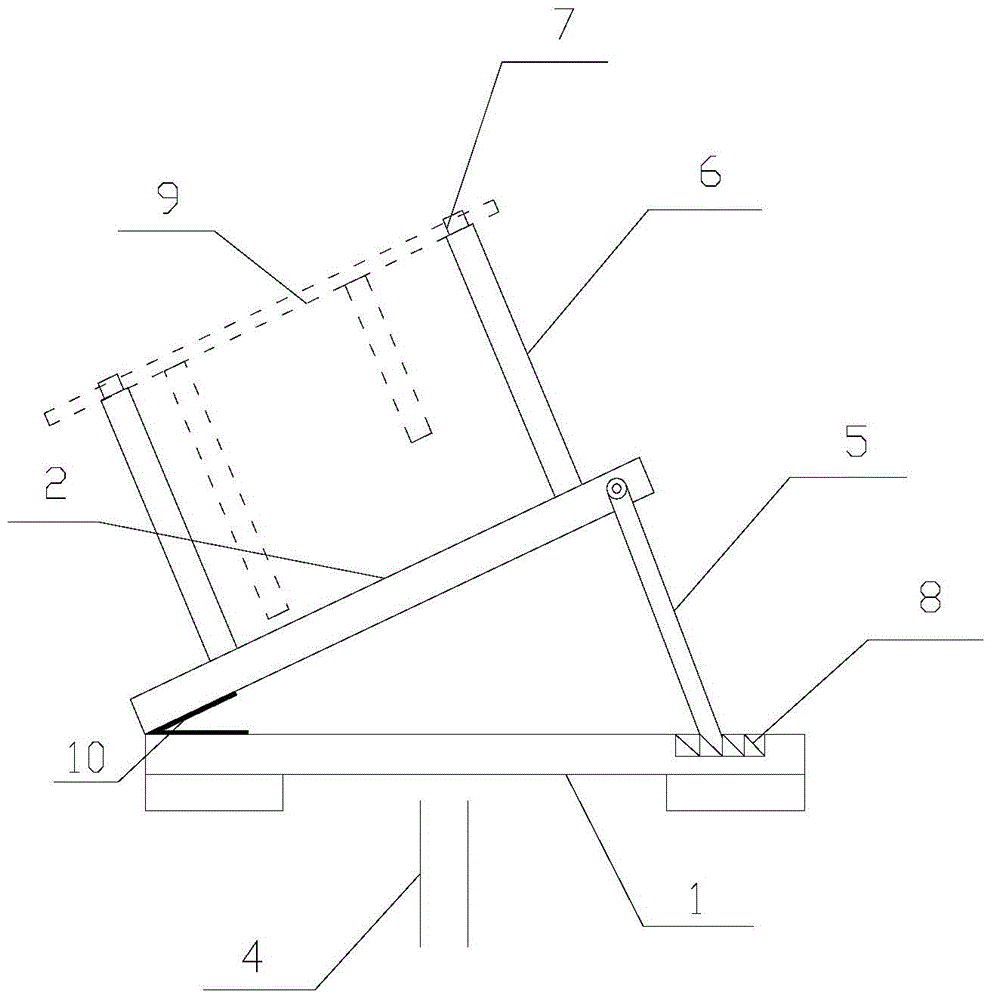

[0028] The traditional cleaning method of the IGBT module cavity is mainly manual cleaning, holding a nitrogen gun in one hand and holding the module in the other hand to perform blowing cleaning. This cleaning method is inconvenient to operate, the cleaning efficiency is low, and it is easy to damage the IGBT module shell The damage of the body cannot guarantee the uniformity and comprehensiveness of the cleaning inside the cavity, and the cleaning effect is poor.

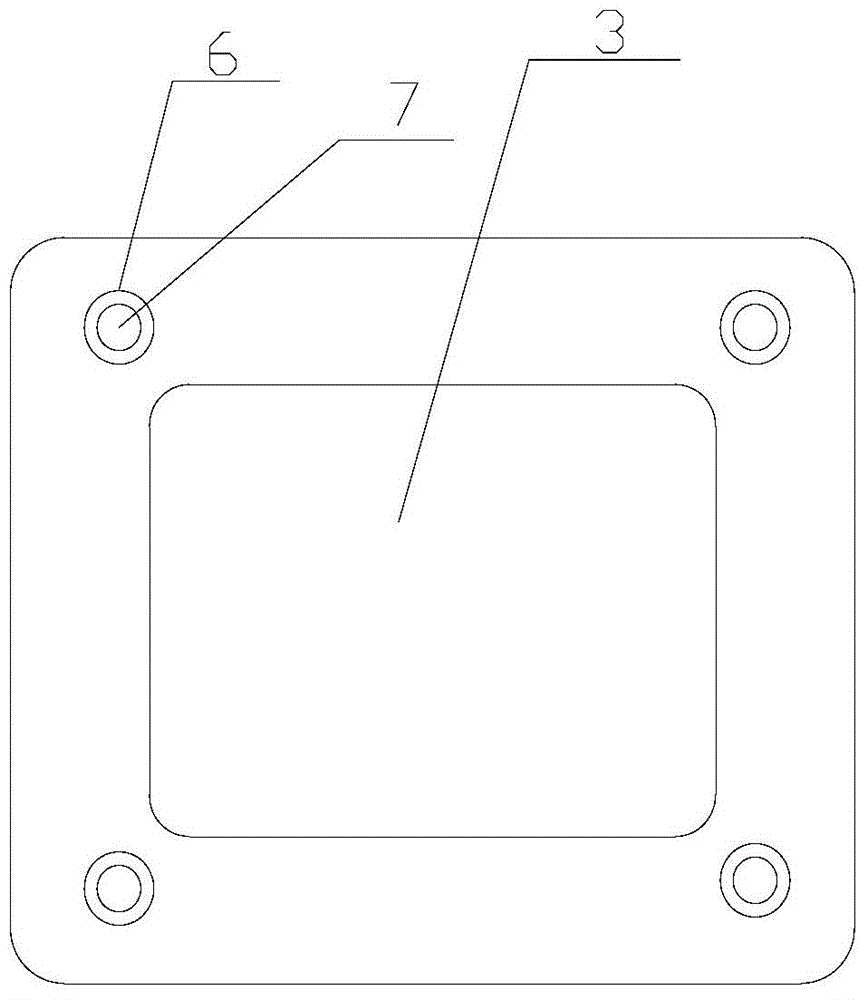

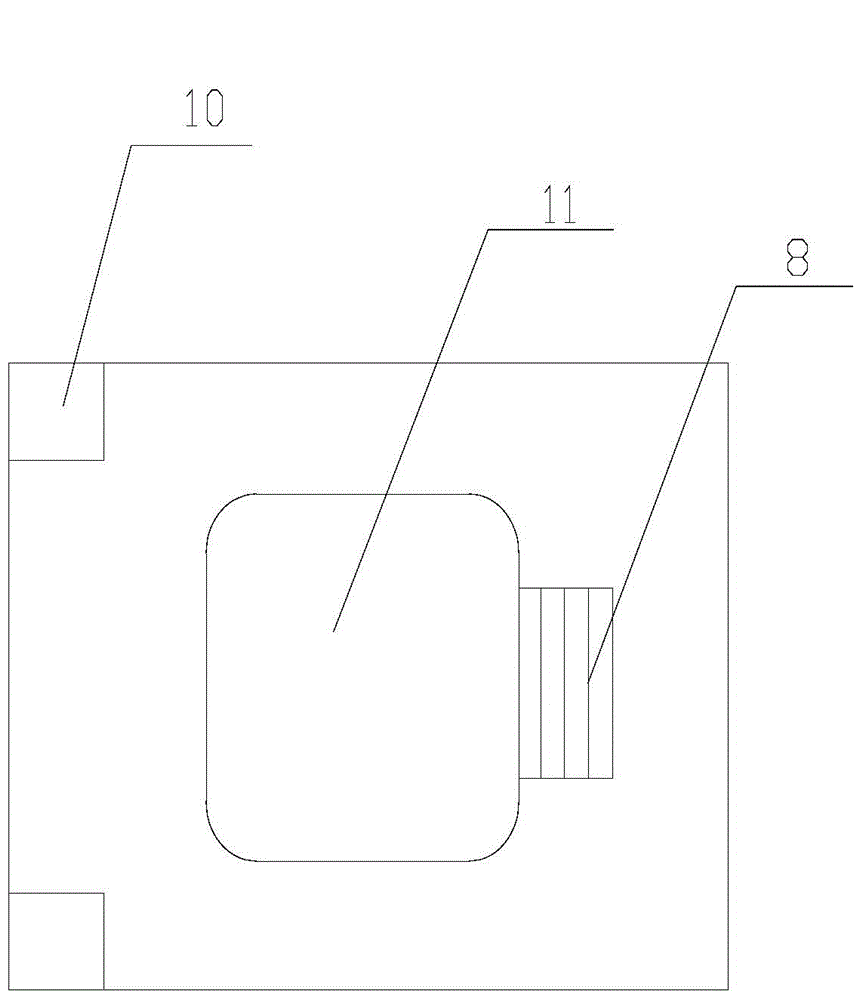

[0029] Aiming at the deficiencies in the prior art, the present invention provides a dust removal tool for the IGBT module cavity and a dust removal method. By using the dust removal tool to effectively position the module, the effective cleaning of the module cavity is realized, and the cleaning efficiency and cleaning quality are improved. , to avoid problems such as damage to the module shell, and to reduce packaging costs.

[0030] The technical solutions of the present invention will be clearly and completely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com