Lotus root digging machine with self-cleaning structure

A lotus root digging machine and self-cleaning technology, applied in the direction of digging harvester, harvester, agricultural machinery and implements, etc., can solve problems such as reducing the service life of the water pump, affecting the normal operation of the water pump, and blocking the filter of the lotus root digging machine. , to achieve the effect of simple structure, firm and reliable fixing, and avoiding repeated maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

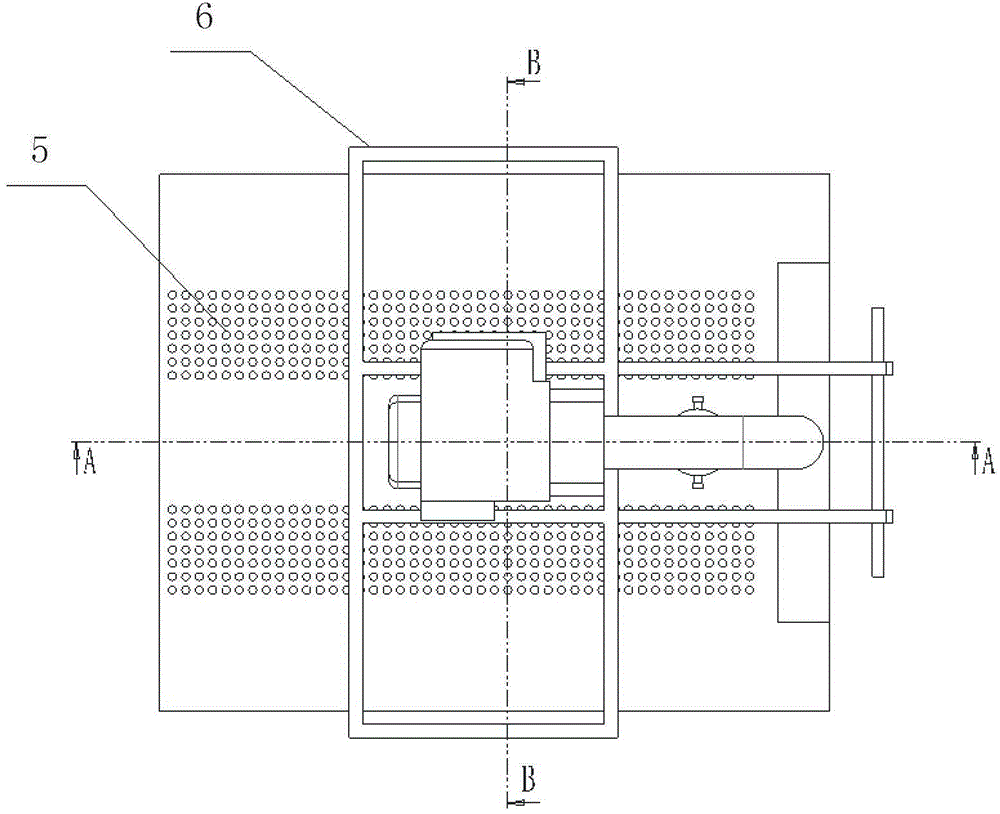

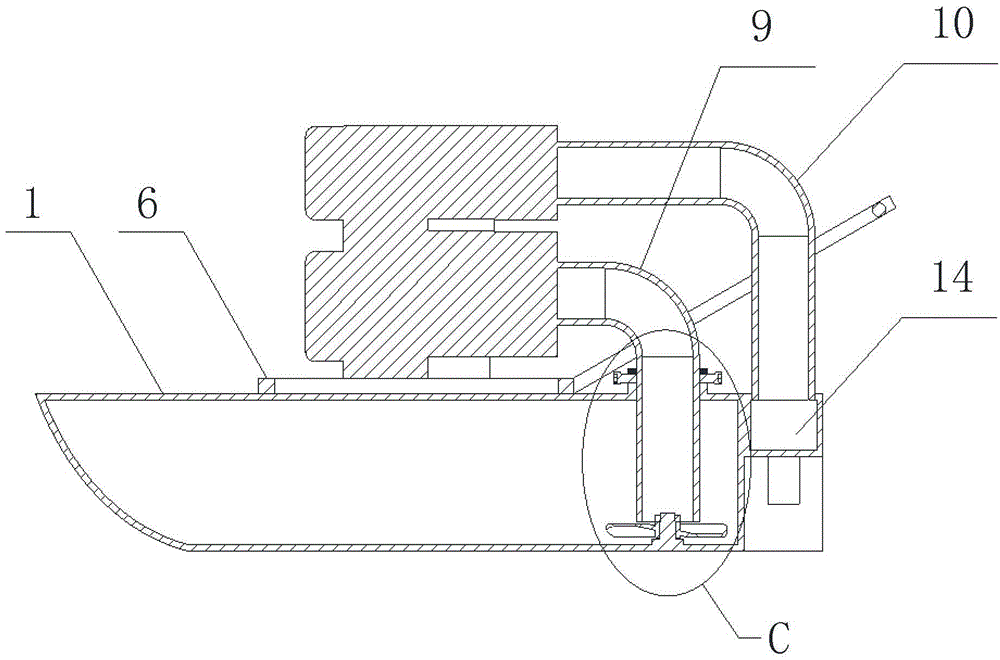

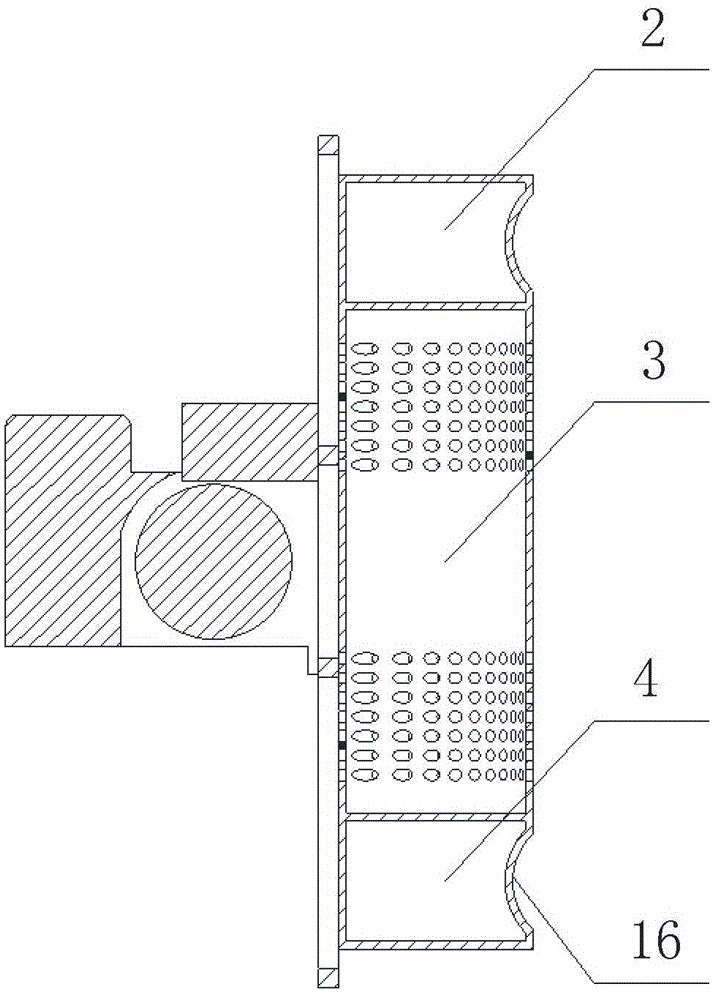

Embodiment 1

[0023] This embodiment provides a lotus root digging machine with a self-cleaning structure. The lotus root digging machine includes a base 1 arranged horizontally. There are three independent and adjacent cavities inside the base 1, which are the first cavity 2 and the second cavity in turn. The cavity 3 and the third cavity 4 are evenly arranged with through holes on the upper and lower surfaces of the base 1 located in the second cavity 3, and a filter screen 5 is formed between the through holes, and the upper end surface of the base 1 is provided with a support Frame 6, the support frame 6 is provided with a water pump 7 and a diesel engine 8 that drives the water pump 7 to work, the water inlet and the water outlet of the water pump 7 are respectively connected with the first pipeline 9 and the second pipeline 10, and one end of the first pipeline 9 extends into the Inside the second cavity 3, a blade mounting seat 11 is provided directly below the mouth of the first pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com