Mechanical separation device for shells and meat of crab legs

A mechanical separation of shell and meat technology, applied in the field of fishery machinery, can solve the problems of high manual labor intensity, product pollution, and inability to realize automation, and achieve the effects of reducing labor intensity, high degree of automation, and improving production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments and drawings.

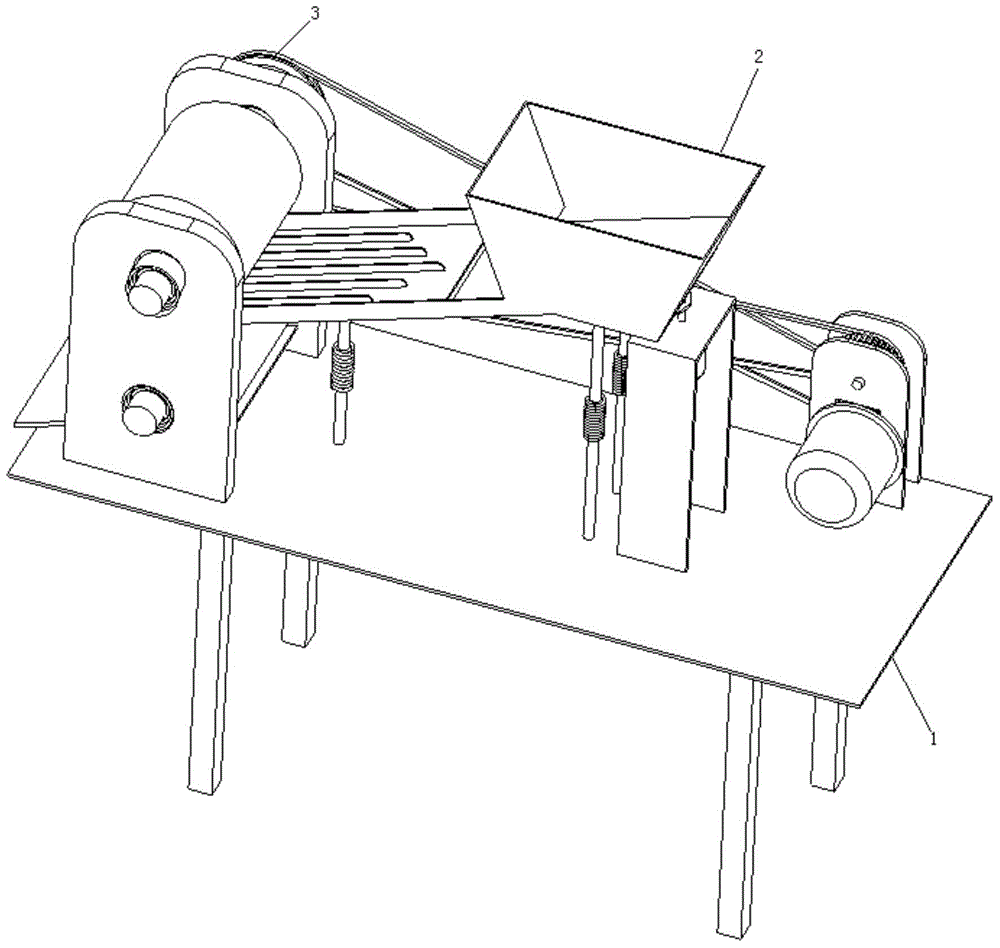

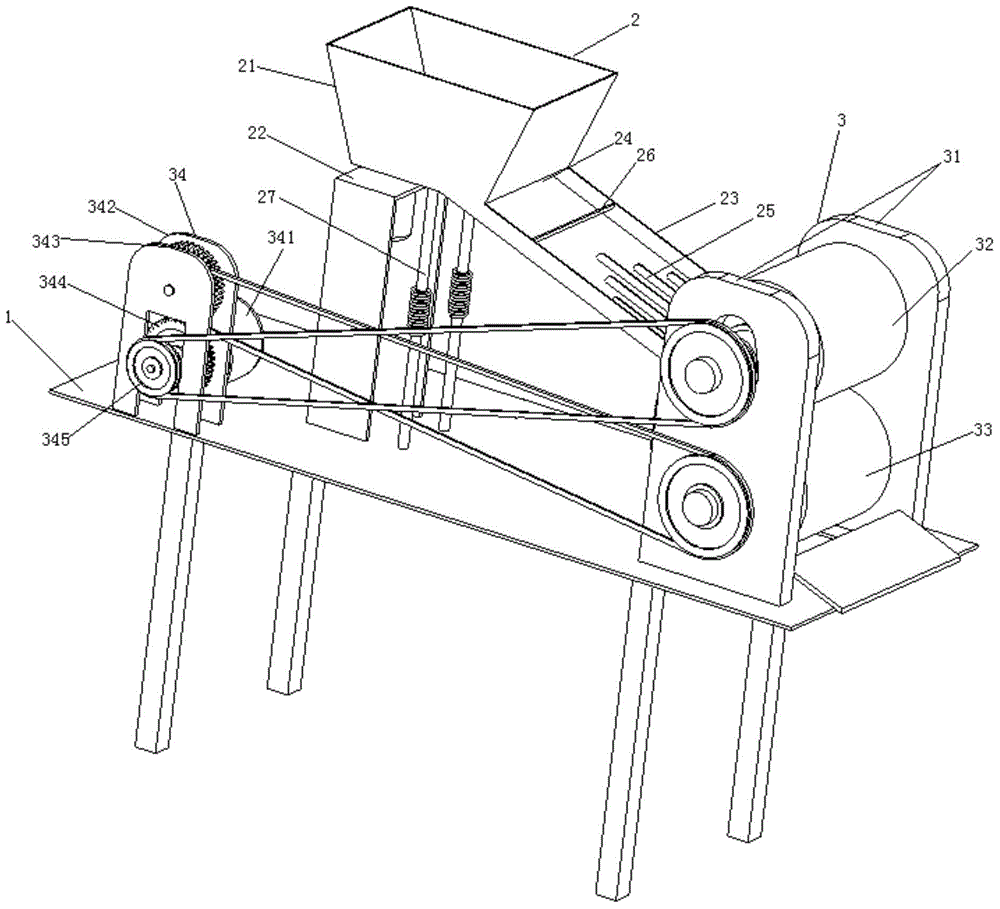

[0024] Such as figure 1 As shown, a mechanical crab leg shell meat separation device includes a worktable 1 and a vibrating feeding mechanism 2 and a roller extrusion mechanism 3 fixed on the front and rear ends of the worktable 1 respectively.

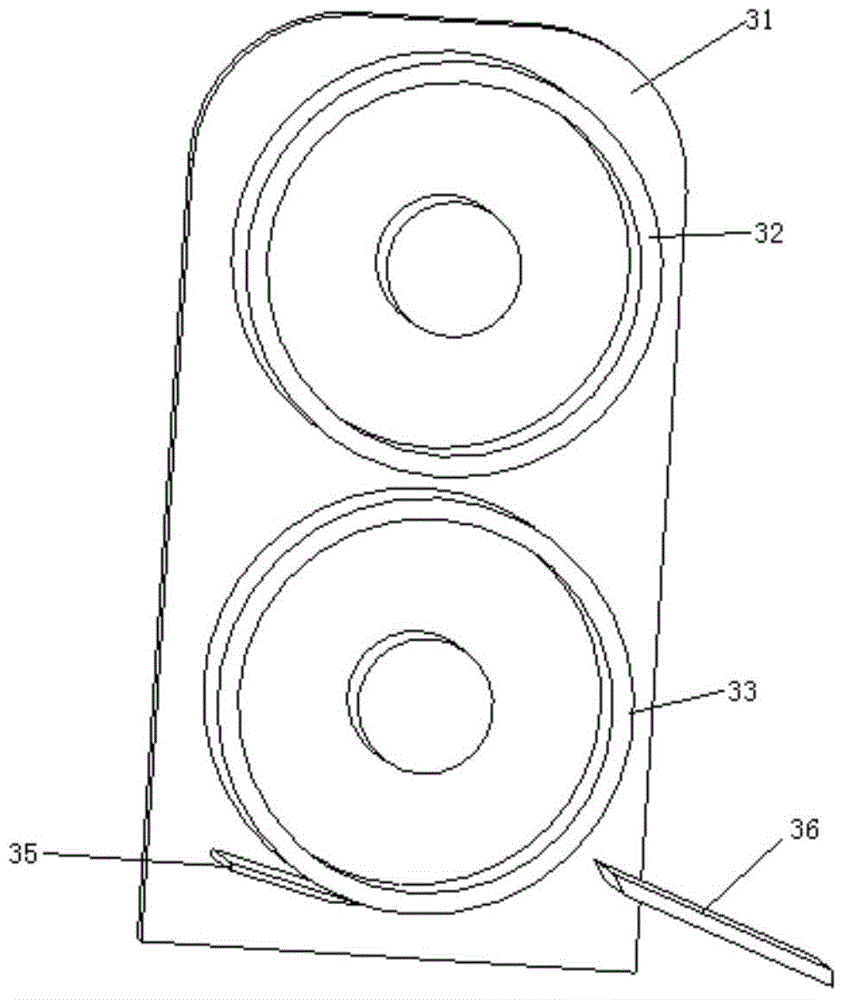

[0025] Such as Figure 2-Figure 3 As shown, the vibrating feeding mechanism 2 includes a hopper 21, a vibration generating device 22, and a conveying slide 23. The hopper 21 is fixed to the front end of the worktable 1 by two symmetrical support rods 27. The rear side wall of the hopper 21 A discharge port 24 is opened at the bottom end. The vibration generator 22 stands at the front end of the worktable 1 and is connected to the bottom of the hopper 21. The front end of the conveying slide 23 is connected to the bottom of the discharge port 24, and the bottom of the rear end is supported by The rod 27 stands on the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com