Electrowelding glasses adopting resin protective lenses

A resin lens and lens technology, applied in the field of glasses, can solve the problems of non-wear resistance, low safety performance, troublesome users, etc., and achieve the effect of good impact resistance and anti-static effect, high safety performance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

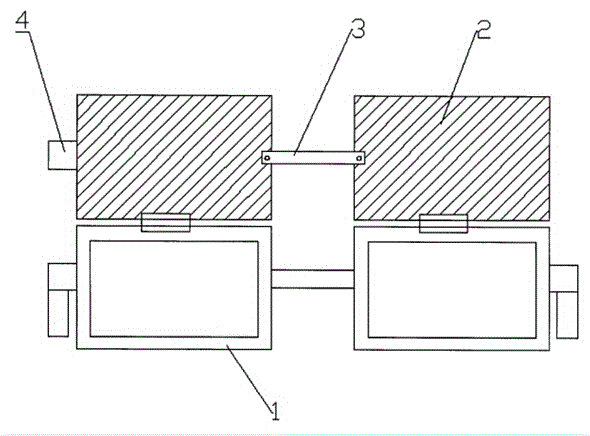

[0015] This embodiment provides a kind of welding glasses adopting resin protective lenses, such as figure 1 As shown, it includes a picture frame 1 and a resin lens 2. There are two resin lenses 2 and they are respectively hinged on the picture frame 1. The two resin lenses 2 are fixed together by a connecting rod 3; one of the two resin lenses 2 formed in one A toggle block 4 is arranged on the side. When the effect needs to be checked for spot welding, the two lenses 2 can be lifted up and opened by simply pushing the toggle block 4 upwards, without taking off the glasses, which is convenient for use.

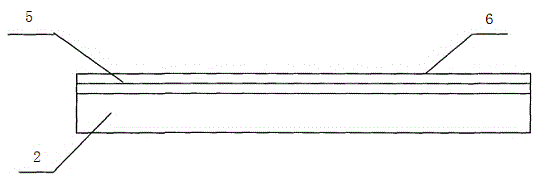

[0016] Such as figure 2 As shown, the resin lens 2 is a diethylene glycol allyl carbonate resin lens, which is light in weight and high in light transmittance; the front surface of the resin lens is provided with a tempered glass layer 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com