Plant extraction equipment for large-scale continuous production

An extraction equipment and large-scale technology, applied in solid solvent extraction and other directions, can solve the problems of hidden safety accidents, incompleteness, huge equipment investment, etc., and achieve the effects of reasonable and compact equipment structure, reduced equipment size, and simple operation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

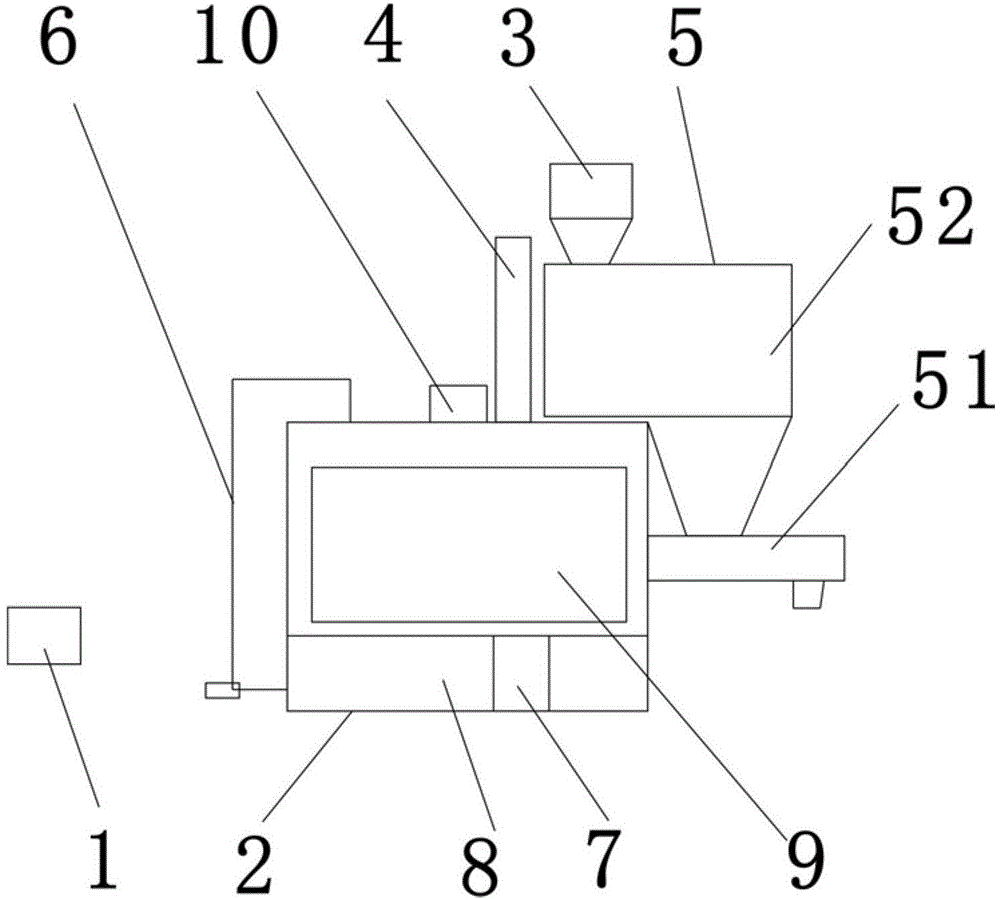

[0056] figure 1 It is a structural schematic diagram of a circular Soxhlet plant continuous extraction device in Example 1 of the present invention. Such as figure 1 As shown, a plant extraction device for large-scale continuous production includes a control device 1, a main body Soxhlet extraction device 2, a feeding device 3 arranged on the main body, a tail gas recovery device 4 and a slag discharge device 5.

[0057] The control device 1 is individually boxed and automatically controls the operation of the entire equipment.

[0058] The main body Soxhlet extraction device 2 is a circular box. The main body is a steel structure, welded by stainless steel materials. The top of the Soxhlet extraction device of the main body is provided with an inlet and outlet sealed opening, and the upper part of the opening is provided with a feeding device 3; an exhaust gas recovery device 4 is installed in the middle of the upper part to facilitate the recycling of condensed exhaust ga...

Embodiment 2

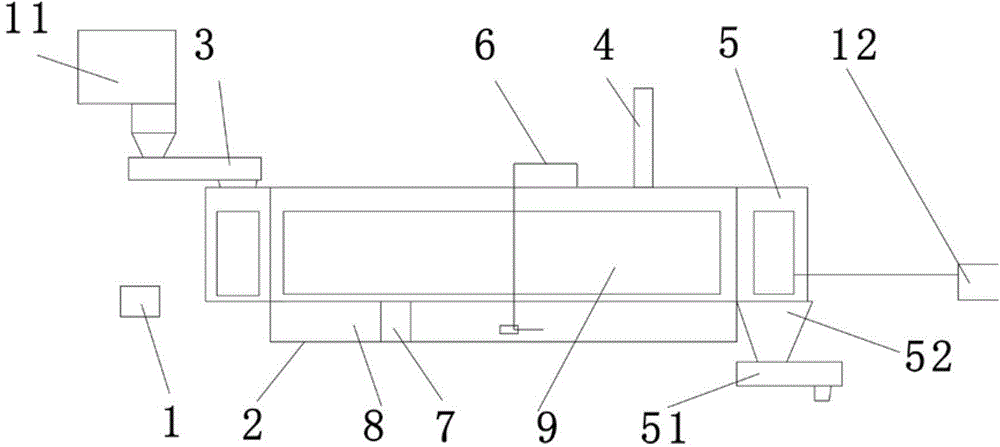

[0069] figure 2 It is a structural schematic diagram of a circular Soxhlet plant continuous extraction device in Example 2 of the present invention. Such as figure 2 As shown, a plant extraction device for large-scale continuous production includes a control device 1, a main body Soxhlet extraction device 2, a feeding device 3 arranged on the main body, a tail gas recovery device 4 and a slag discharge device 5.

[0070] The control device 1 is individually boxed and automatically controls the operation of the entire equipment.

[0071] The main body Soxhlet extraction device 2 is a rectangular box. The main body is stainless steel structure, welded by stainless steel material. The top of the Soxhlet extraction device of the main body is provided with an inlet and outlet sealing opening, and the upper part of the opening is provided with a feeding device 3; there is an exhaust gas recovery device 4 in the middle of the upper part, which is convenient for the recycling of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com